Method for smooth blasting excavation of large-diameter surge shaft and long-footage pilot well in soft-rock and extremely-soft-rock area

A technology of smooth blasting and surge wells, which is applied to the smooth blasting excavation method of pilot wells with large diameter surge wells in extremely soft rock areas, soft rock fields, and can solve the problems affecting the progress, cost, quality and safety of surge wells , Surrounding rock and lining concrete deformation, and lining work difficulties, etc., to improve the construction method, shorten the construction period, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

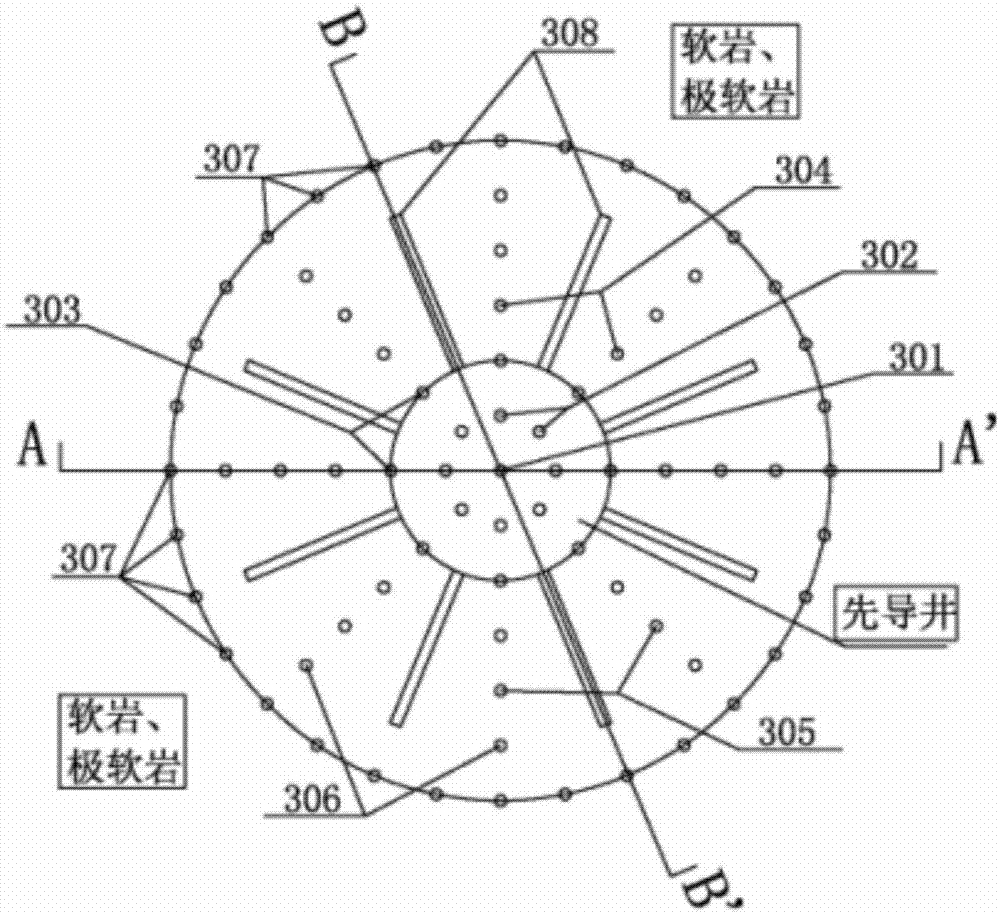

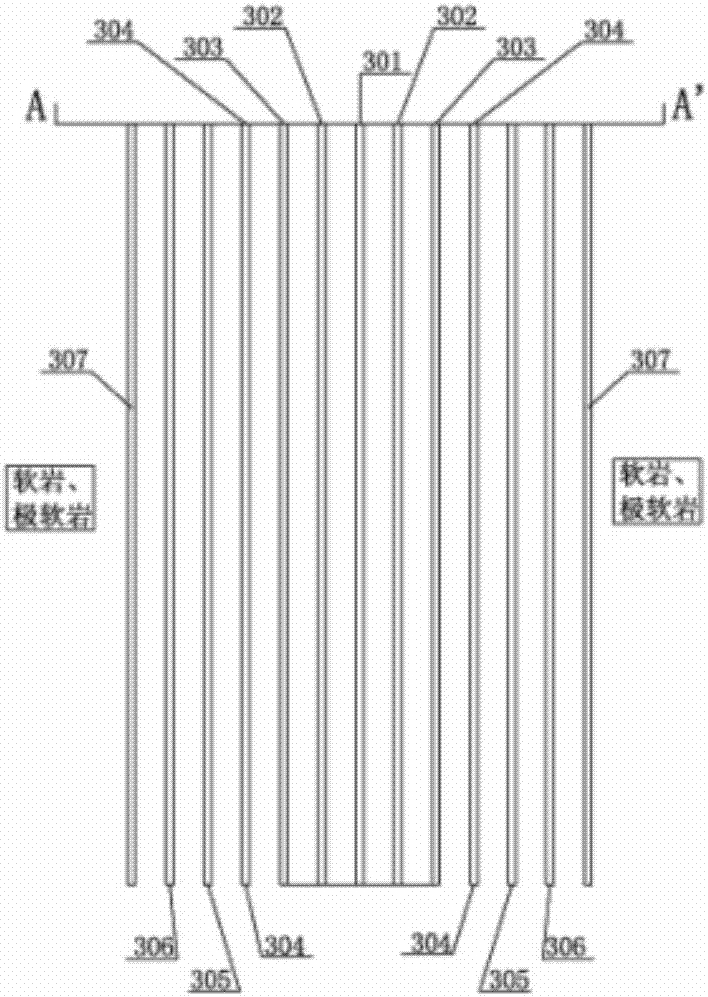

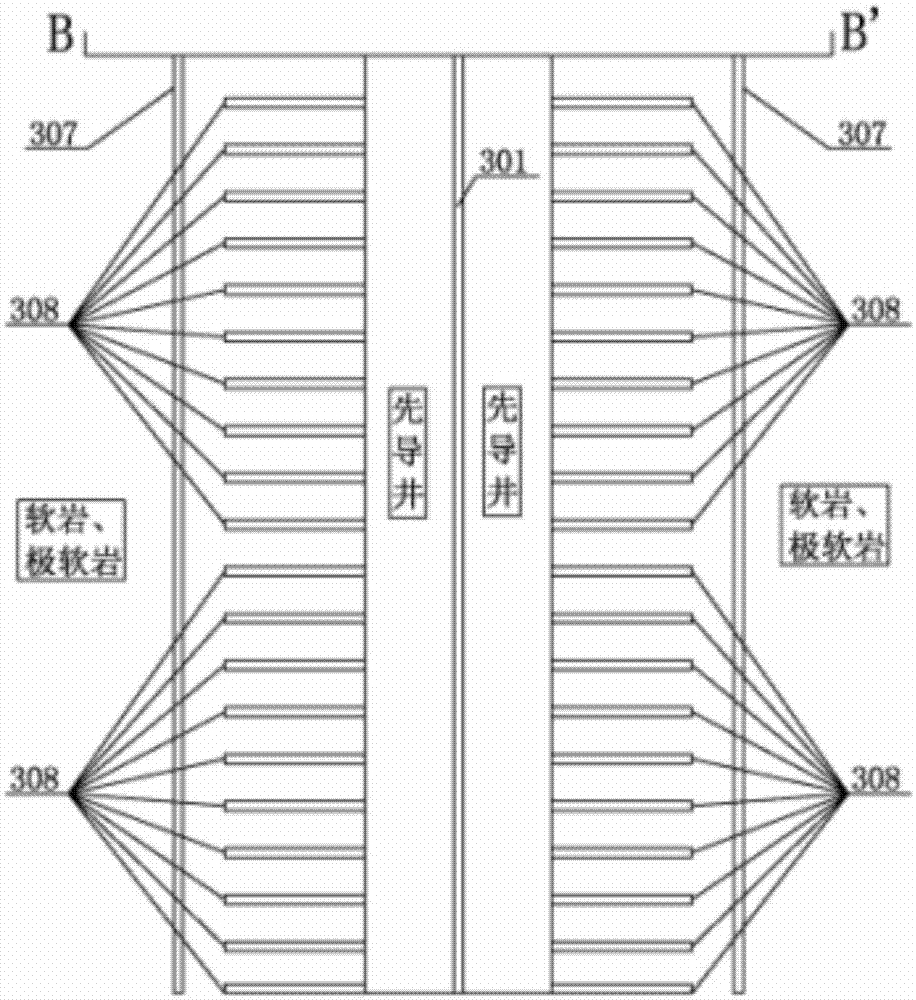

[0034] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] Take a surge well with a diameter of 12 meters and a depth of 20 meters as an example to implement the technical proposal of the present invention.

[0036] A smooth surface blasting excavation method of a large-diameter surge well with a length and footage of a pilot well in soft rock and extremely soft rock areas is characterized in that it includes the following steps:

[0037] (A) Long footage pilot well excavation

[0038] The pilot well is arranged in the center of the circular excavation surface, forming a concentric circle structure with the excavation surface. The excavation depth of the pilot well runs through the surge well, and the diameter of the pilot well is one-third of the diameter of the surge well;

[0039] I. Layout of blast holes for pilot wells

[0040] A central blast hole 301 is arranged at the center of the pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com