Low-nitrogen gas boiler burner

A gas-fired boiler and burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of high primary air combustion composition requirements, affecting thermal efficiency, NOx emissions, and affecting production safety, etc., to reduce temperature, Reduced residence time and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

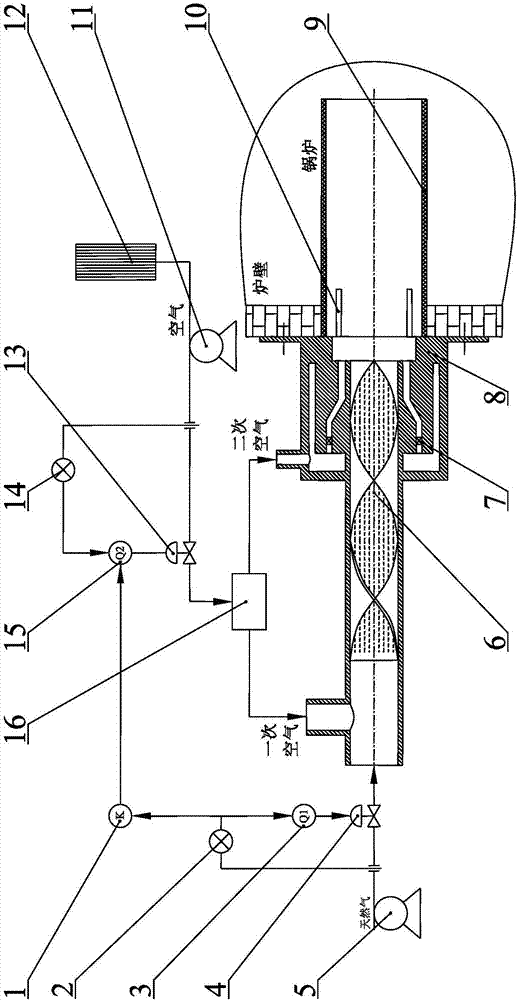

[0014] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] see figure 1 , flow signal transmitter 2, flow controller 3, control valve 4 and gas source 5 constitute a gas flow control circuit; flow signal transmitter 14, flow controller 15, control valve 13, fan 11 and air filter 12 constitutes an air flow control circuit; a ratio device 1 is set between the gas flow control circuit and the air flow control circuit; one end of the proportional flow valve 16 is connected to the air flow control circuit, and the other end is respectively connected to the primary air inlet and secondary air The inlets are connected; one end of the igniter 10 is fixed on the mixing pipe 8, and one end goes deep into the boiler; one end of the metal fiber combustion head 9 is installed concentrically through the furnace wall and the mixing pipe 8, and the other end is located in the boiler....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com