Automatic plate shearing system

A shearing and automatic technology, applied in the direction of shearing devices, shearing equipment, feeding devices, etc., can solve the problems of labor consumption, large plate quality, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

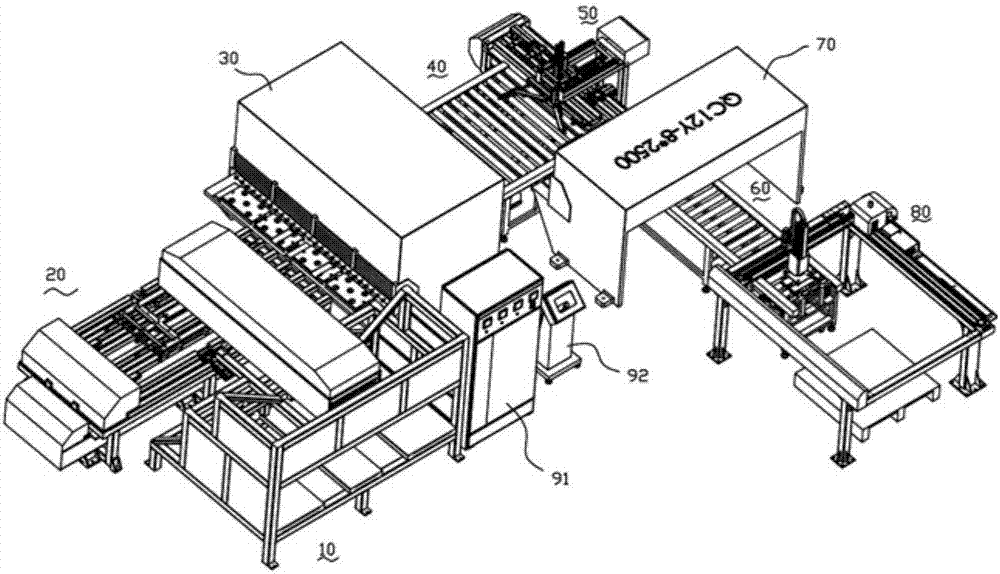

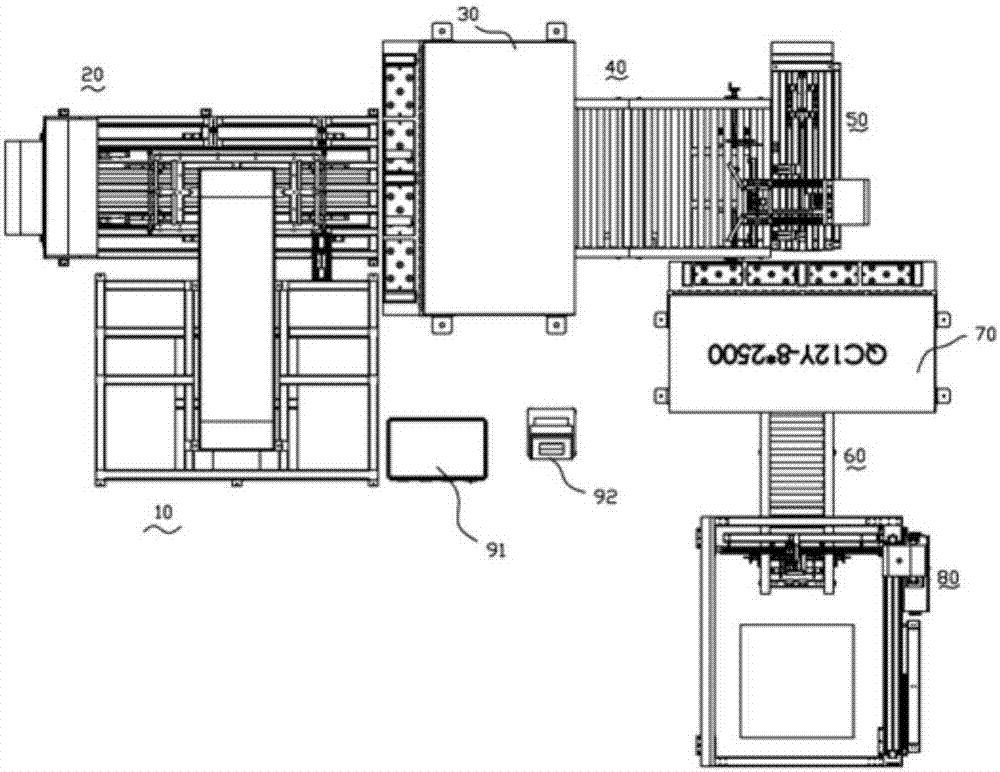

[0031] Such as Figure 1 to Figure 15 As shown, an automatic shearing system includes a raw material feeding and handling assembly 10, a raw material servo feeding assembly 20, a first shearing machine 30, a strip fixed-point transmission assembly 40, a strip feeding and handling assembly 50, and a second shearing machine 60. The finished product fixed-point transmission component 70 and the stacking and handling component 80, the material loading and handling component 10, the raw material servo feeding component 20, the first shearer 30, the strip fixed-point transmission component 40, the strip feeding and handling component 50, the first The second shearing machine 60, the finished product fixed-point transmission assembly 70 and the stacking and handling assembly 80 are arranged sequentially; the raw material loading and handling assembly 10 includes a raw material handling frame 11, and a motion box 13 is installed on the raw material handling frame 11, so that A horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com