Forming device and method of mesh-shaped steel framework

A forming device and steel skeleton technology, applied to wire mesh, other household appliances, household appliances, etc., can solve the problems of difficult adjustment of tension force, poor welding effect, increased resistance, etc., to save threading time, good welding quality, close contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through specific examples.

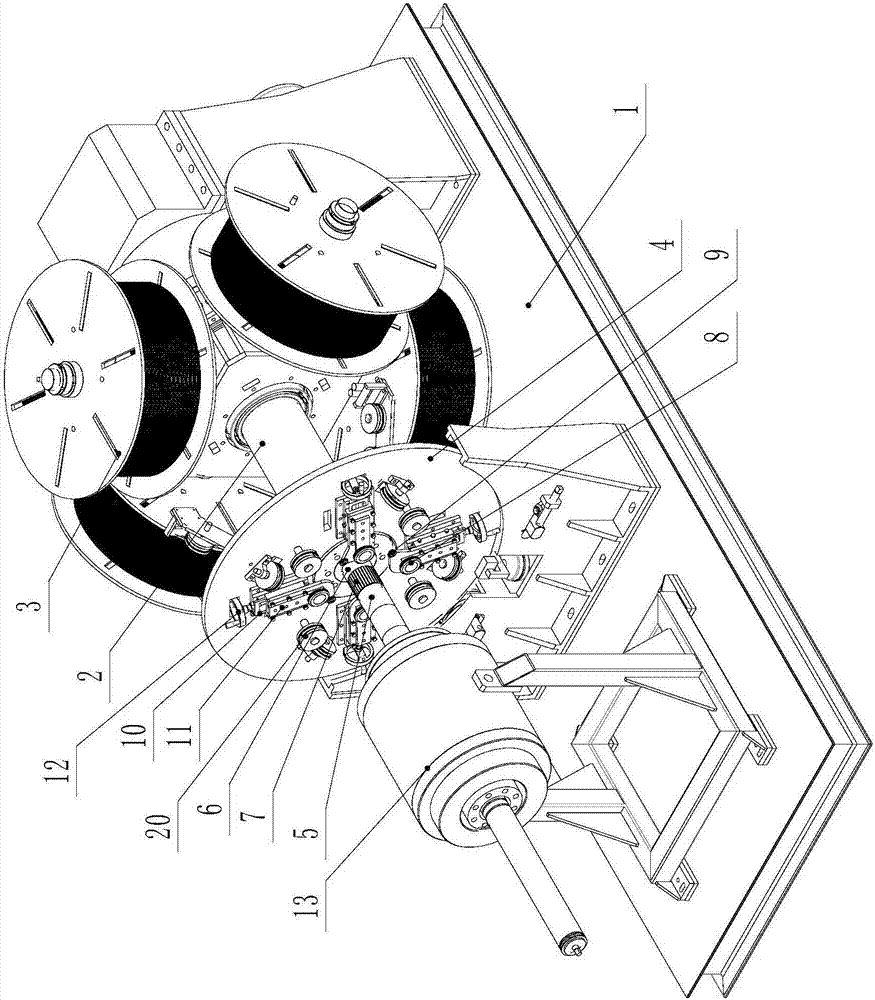

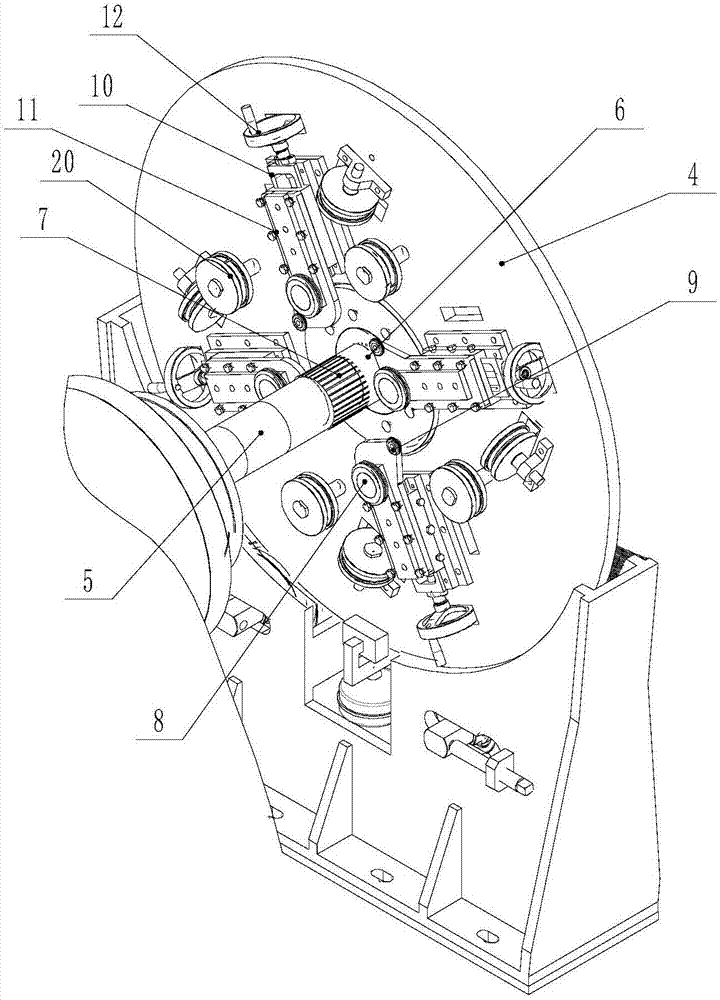

[0036] Such as Figure 1-11A forming device for a reticulated steel skeleton is shown, comprising a frame 1 on which a rotating frame 2 is rotatably installed, and the rotating frame 2 is driven by a rotating power device 16, wherein the frame 1 includes a machine seat and the upstream support and downstream support located on the machine base, the rotating frame 2 is installed between the upstream support and the downstream support, and the mode of this embodiment is that the upstream support and the downstream support are rotatably installed with A hollow support shaft 19, and the swivel frame 2 is mounted on the support shaft 19 through bearing rotation, and the inner hole of the hollow support shaft 19 constitutes an insertion hole. The rotary power unit 16 is driven by a motor and driven by a chain. The rotating frame 2 is provided with a rotating conductive ring 15 for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com