Full coverage type one-time smooth electrode light emitting diode and manufacturing method thereof

A light-emitting diode, full-coverage technology, applied to circuits, electrical components, semiconductor devices, etc., can solve problems such as poor adhesion of metal layers, inability to carry out large-scale mass production, and affect product quality and yield, so as to reduce pollution and solution contact denaturation, avoiding electrode edge shedding, improving quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] 1. Manufacturing process:

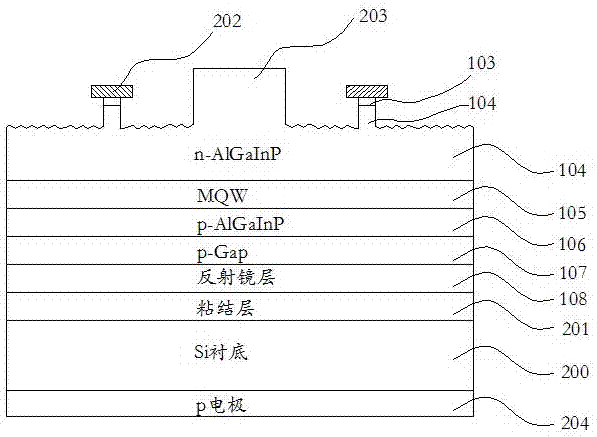

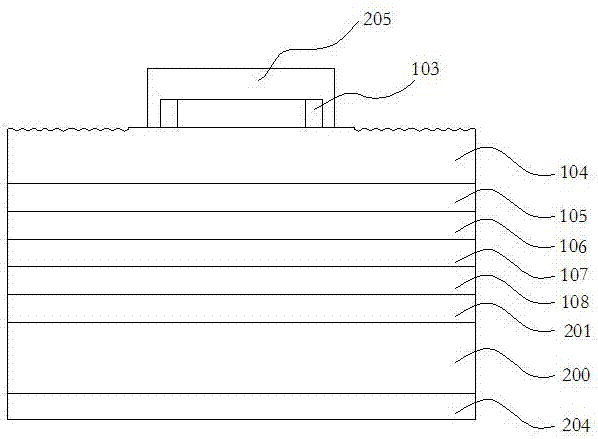

[0027] 1. Preparation of the light-emitting diode epitaxial wafer: on one side of a temporary GaAs substrate 100, the buffer layer 101, the barrier layer 102, the n-GaAs ohmic contact layer 103, and n-AIGaInP are used to epitaxially grow the buffer layer 101, the barrier layer 102, and the n-AIGaInP in sequence. Layer 104, MQW multiple quantum well active layer 105, p-AIGaInP confinement layer 106, and p-GaP window layer 107.

[0028] The mirror layer 108 is vapor-deposited on the p-GaP window layer 107, and SiO 2 Evaporate, in SiO 2 Conductive small holes are opened on the layer, and then Ag is evaporated.

[0029] The mirror layer 108 also functions to form an ohmic contact with the p-GaP window layer 107. Among them, it uses SiO with conductive small holes 2 The layer can adjust the number, distribution, aperture, and spacing of small holes according to actual needs, so as to adjust the conductive effect and reflection effect of the chip, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com