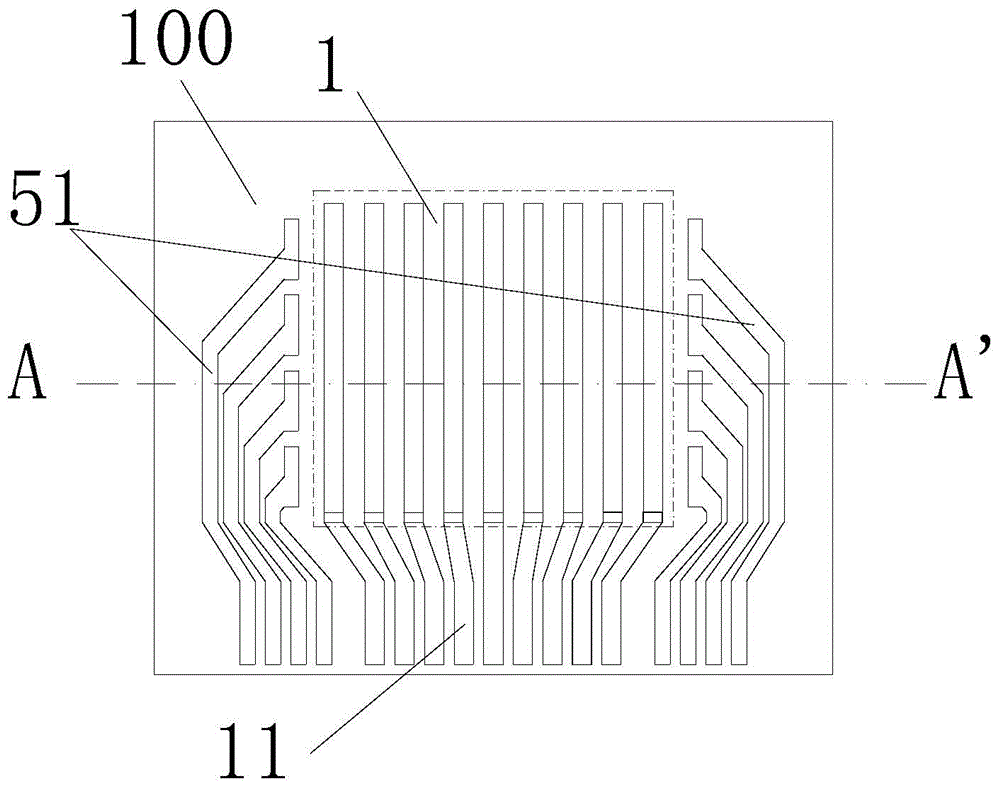

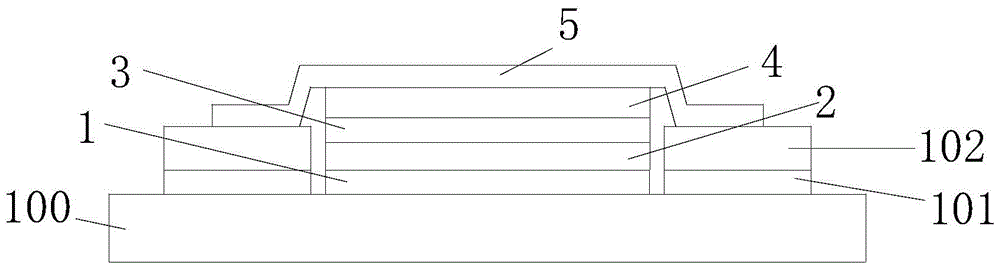

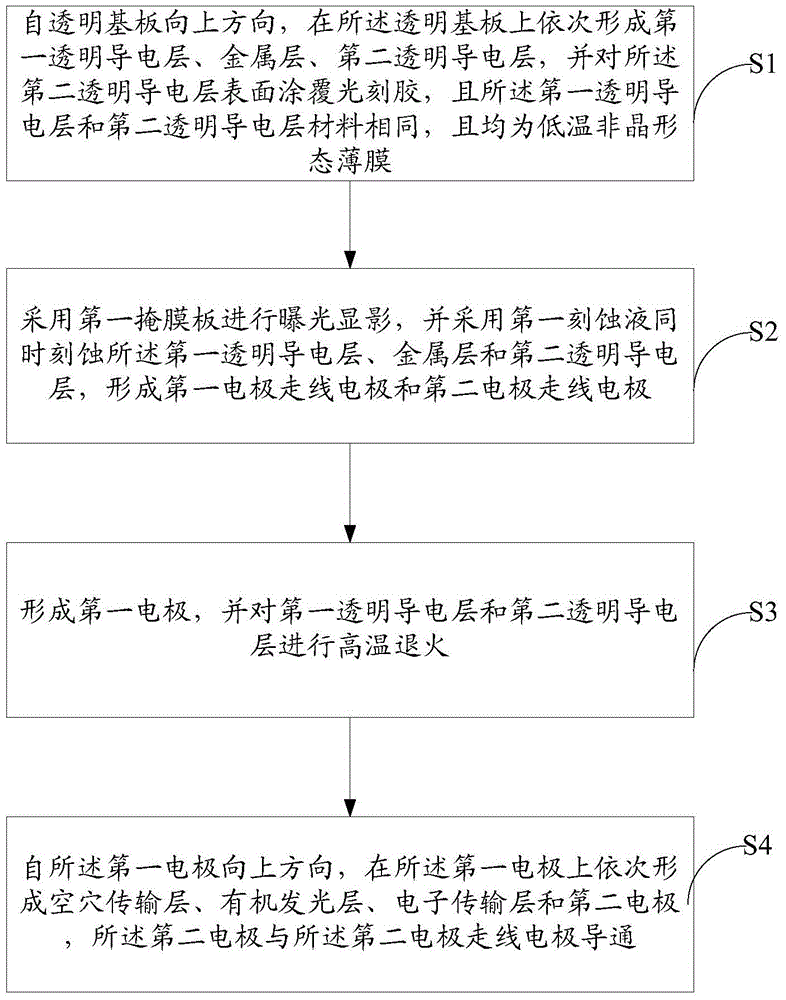

A low-power organic electroluminescent display device and manufacturing method

A technology of display device and manufacturing method, which is applied in the direction of electric solid state device, semiconductor/solid state device manufacturing, electrical components, etc., can solve the problems of low product yield, complicated process, excessive etching of the second conductive layer, etc. The effect of low, power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] As described in the background technology, but in the production process of existing OLEDs, especially in the production process of the first electrode wiring electrodes and the second electrode wiring electrodes, not only the process is complicated, but also the first electrode wiring electrodes and the second electrode wiring electrodes often appear. The phenomenon that the second conductive layer of the second electrode wiring electrode is etched too much leads to a low yield rate of the product. The inventor found that the cause of this defect is mainly due to the use of layered exposure etching when making the first electrode wiring electrodes and the second electrode wiring electrodes, that is, the first electrode wiring area and the second electrode wiring area need to be The wiring area is subjected to two exposures and etching, and the position shift is prone to occur in the two exposures and etchings, which leads to the phenomenon that the second conductive lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com