Use method of high-speed sizing machine warp beam brake belt and warp beam brake belt

A brake belt and sizing machine technology, applied in the field of warp beam brake belt and high-speed sizing machine warp beam brake belt, can solve the problem of increasing maintenance time and machine material cost, shortening the use length of iron chain, and sizing return. The problem of increased wire rate, etc., can achieve the effect of large pressing surface, improving efficiency and no expansion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

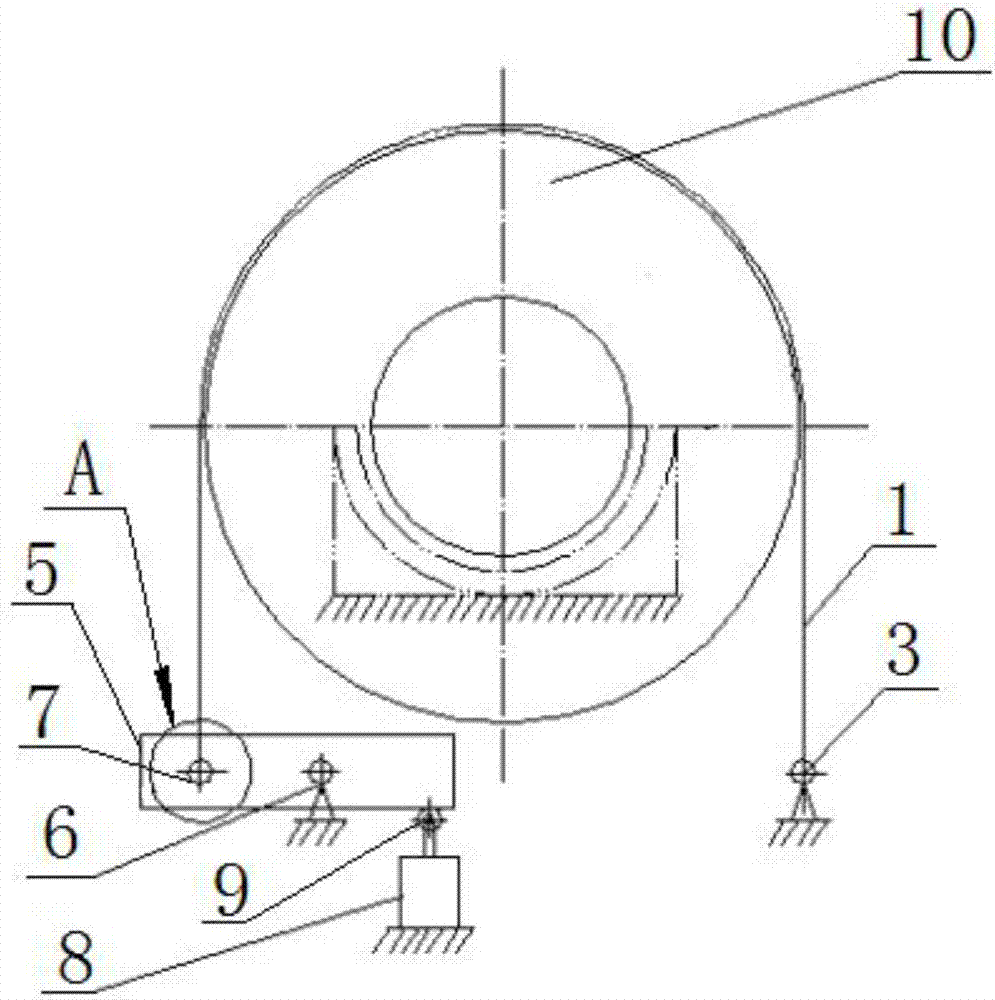

[0026] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

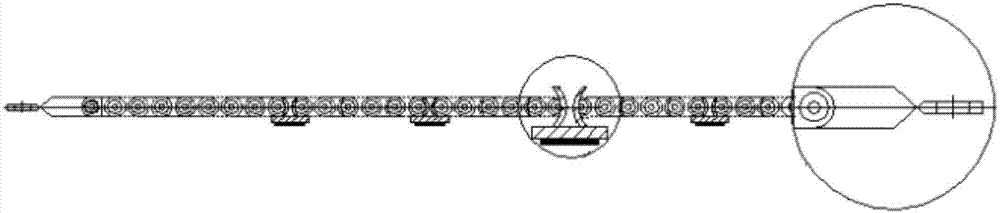

[0027] Referring to the accompanying drawings, it can be seen that the method for using the warp beam braking band of a high-speed sizing machine is characterized in that: comprising the following steps:

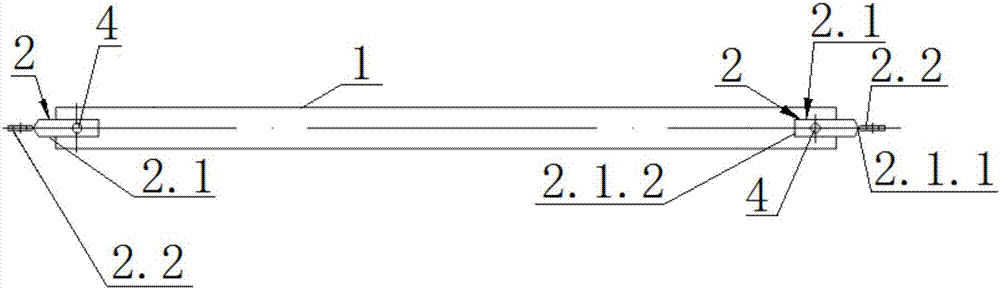

[0028] Step 1: Fix the two base belt connecting pendants 2 to the left and right ends of the warp beam braking band respectively, and the warp beam braking band is the base braking band 1;

[0029] Step 2: Fix one end of the hook 2.2 at one end of the base brake band 1 to the fixed fulcrum 3 of the brake band; fix one end of the hook 2.2 at the other end of the base brake band 1 on the hanging post 7; brake the base Belt 1 is tensioned o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com