Fan blade

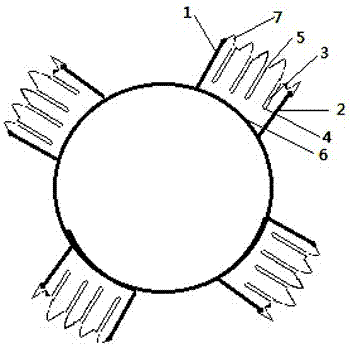

A fan blade and blade technology is applied in the field of fan structure design to achieve the effect of suppressing eddy current detachment and reducing backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A small single-rotor fan for household use has 12 incisions on the blade, the incisions penetrate the front and rear surfaces of the blade, the incision closest to the leading edge of the fan blade is located at 1 / 10 arc length from the leading edge of the fan blade, and the incision closest to the trailing edge of the fan blade Located 1 / 10 of the arc length from the trailing edge of the fan blade, between the two rows of slits 1 / 10 of the arc length from the leading edge and the trailing edge of the fan blade, several slits are arranged in sequence, with a distance of 10mm between the slits, and the lower ends of the slits are closed at the distance from At 8mm from the lower edge of the blade, the upper end of the incision is opened on the upper edge of the blade; the inclination angle of the incision against the wind is 65°, and the incision width is 3mm.

Embodiment 2

[0016] For household counter-rotating double-rotor fans, the front and rear blades are arranged in pairs, and the cutouts are arranged on each blade as in Example 1.

Embodiment 3

[0018] For a small single-rotor fan for household use, the blades are arranged with cutouts as in Example 1. In addition, the upper edge of the fan blades is set in a zigzag shape with a tooth width of 5 mm and a tooth pitch of 6 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth width | aaaaa | aaaaa |

| Tooth pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com