Urea pumping system

A technology of urea pump and urea tank, which is applied in the direction of exhaust gas treatment, machine/engine, mechanical equipment, etc. It can solve the problems of necessary compressed air source, easy crystallization of urea, complex structure, etc., and achieve good effect, low cost and stable pressure sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

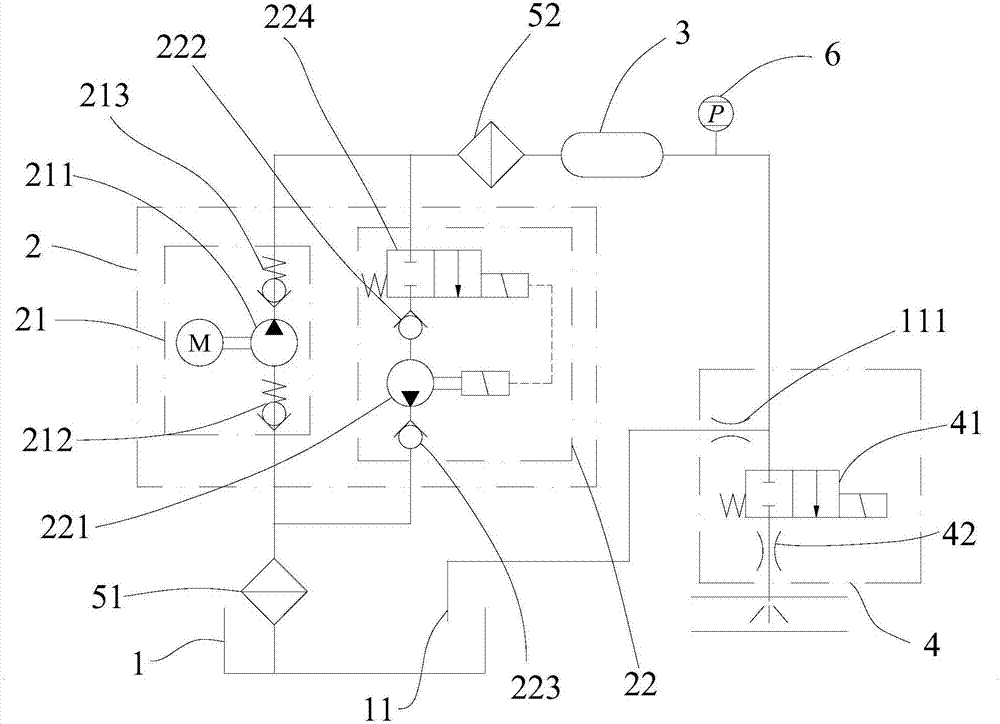

[0022] Such as figure 1 As shown, the urea pumping system in this embodiment includes a urea tank 1, a urea pump module 2, an accumulator 3, and a nozzle module 4 connected in sequence through pipelines, and the urea pump module 2 includes a parallel set for pumping urea The liquid in the tank 1 is pumped to the main pump 21 of the nozzle module 4 and the auxiliary pump 22 for reversely sucking the liquid in the pipeline back to the urea tank 1. The nozzle module 4 includes a first solenoid valve 41 and an atomizing nozzle , the first electromagnetic valve 41 is respectively connected to the accumulator 3 and the atomizing nozzle through pipelines, and the pipeline between the first electromagnetic valve 41 and the accumulator 3 is provided with a return pipeline 11 communicated with the urea tank 1, and the return pipe A first damping hole 111 is opened on the road 11 .

[0023] The main pump 21 transports the solution in the forward direction, and the auxiliary pump 22 reve...

Embodiment 2

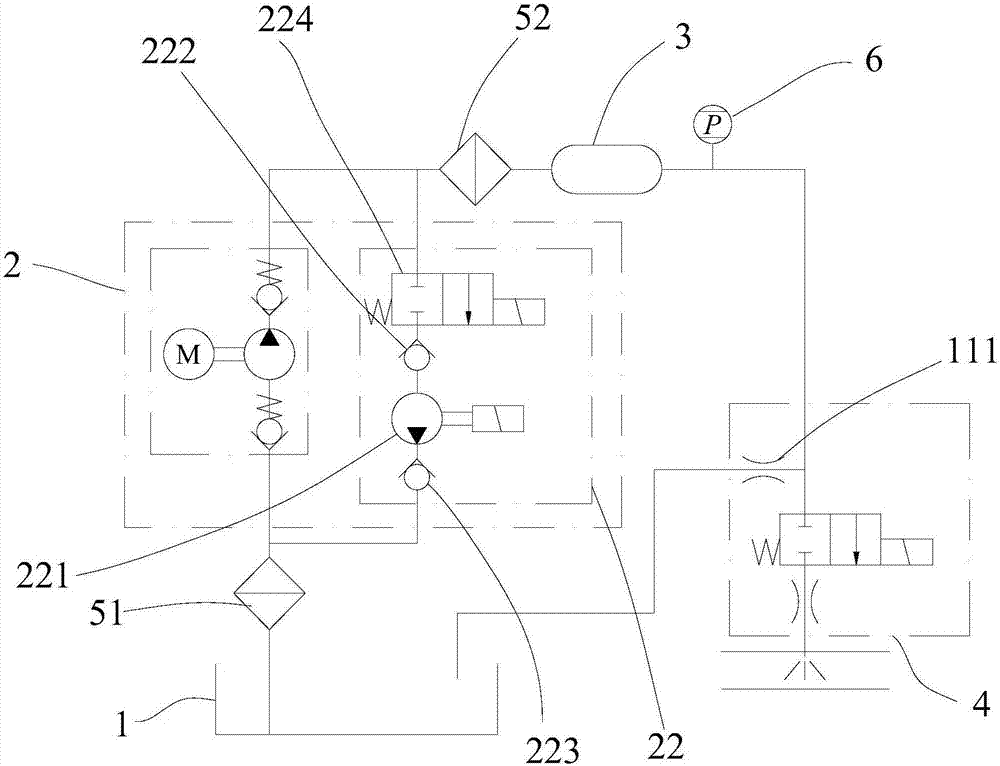

[0034] Such as figure 2 As shown, the main difference between this embodiment and Embodiment 1 is that the electromagnetically driven pump 221 and the second electromagnetic valve 224 are driven and controlled separately. All the other parts are identical to the structure of embodiment 1.

Embodiment 3

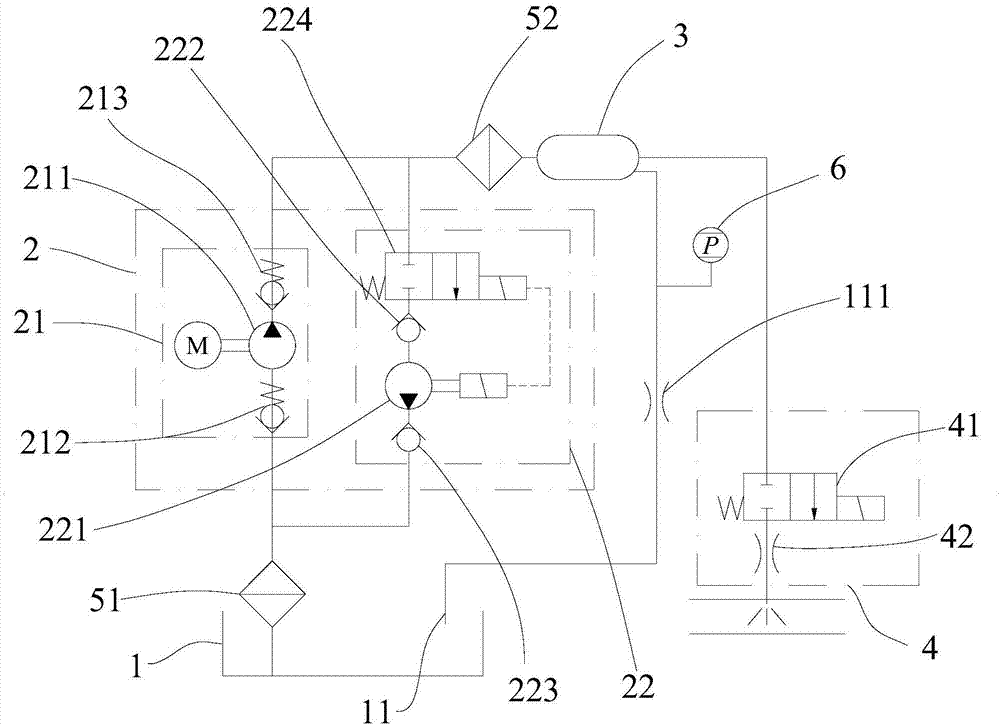

[0036] Such as image 3 As shown, the main difference between this embodiment and Embodiment 1 is that: the return pipeline 11 is arranged to be connected with the accumulator 3 , and the pressure sensor 6 is arranged on the return pipeline 11 . All the other parts are identical to the structure of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com