Pile detecting hole obstacle clearing device based on churn drill

A technology of cleaning device and impact drill, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of detection equipment not working normally, clogging, etc., and achieve the effect of ingenious structural design and good fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

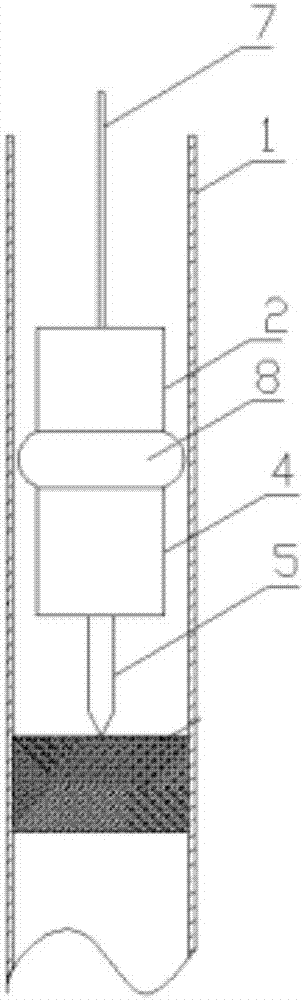

[0022] Embodiment 1: a kind of obstacle clearing device based on the measuring pile hole of percussion drill, as figure 1 As shown, it includes a connecting line 7, a counterweight 2, a pipe fixing device and a percussion drill 4, and the pipeline fixing device is located between the counterweight and the percussion drill, and the front end of the percussion drill is provided with a drill bit 5 , the connecting wire 7 is electrically connected to the impact drill 4;

[0023] The connection line 7 , the counterweight 2 , the pipe fixing device and the percussion drill 4 are all located in the pile measuring hole 1 .

[0024] The pipeline fixing device is an air bag 8 .

[0025] The airbag is a cylindrical airbag.

[0026] The connecting wires 7 include power wires and steel wires.

[0027] The drill bit 5 is a point drill bit, a needle drill bit or a cylinder drill bit.

Embodiment 2

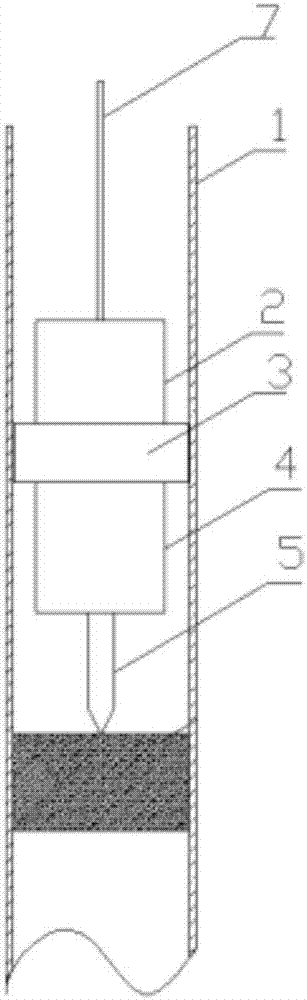

[0028] Embodiment 2: a kind of obstacle cleaning device based on the measuring pile hole of percussion drill, as figure 2 As shown, the structure is basically the same as that of Embodiment 1, except that the pipeline fixing device is a hydraulic telescopic device 3 .

[0029] Working principle or working process of the present invention are as follows:

[0030] The cleaning device is slowly put into the pipeline. When the drill bit encounters an obstacle in the pipeline, the counterweight generates a vertical downward force due to gravity. When the hydraulic expansion device receives the vertical force, it expands horizontally and fixes the cleaning device on the The inner wall of the pipe or the air bag deforms when it is under the pressure of the counterweight, and the diameter becomes larger, and it is close to the inner wall of the pile measuring hole pipe to prevent the impact drill from rotating in the horizontal direction of the pile measuring hole to achieve the purp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com