Flexible shed tunnel

A shed-hole and flexible technology, applied in construction, protective equipment and other directions, can solve the problems of limited energy consumption capacity, difficult replacement, large area of a single mesh, etc., to achieve low cost, reasonable energy consumption form, and clever concept. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

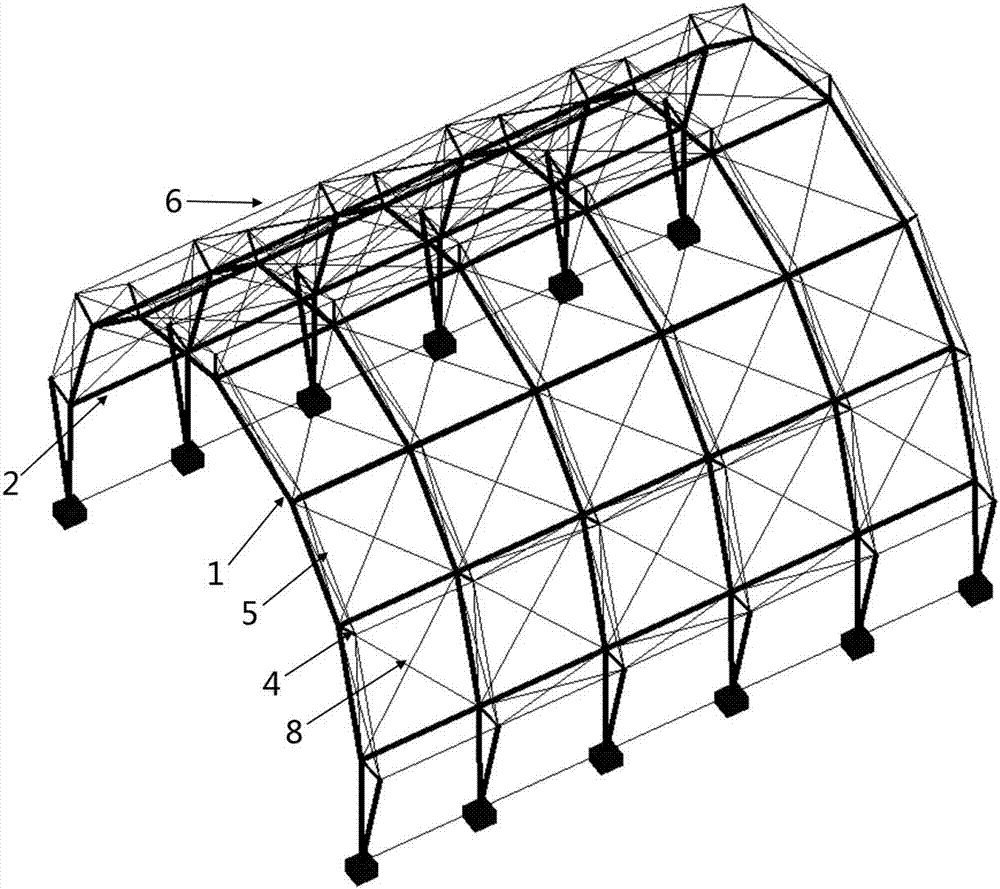

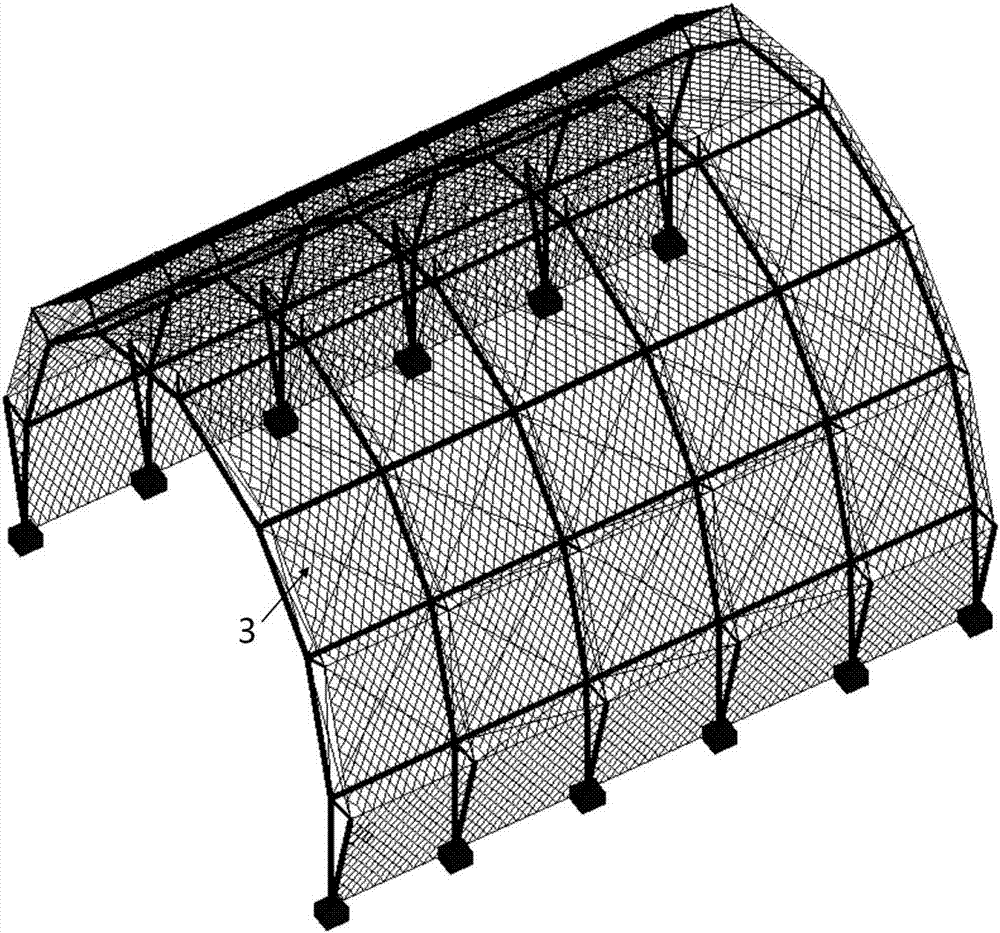

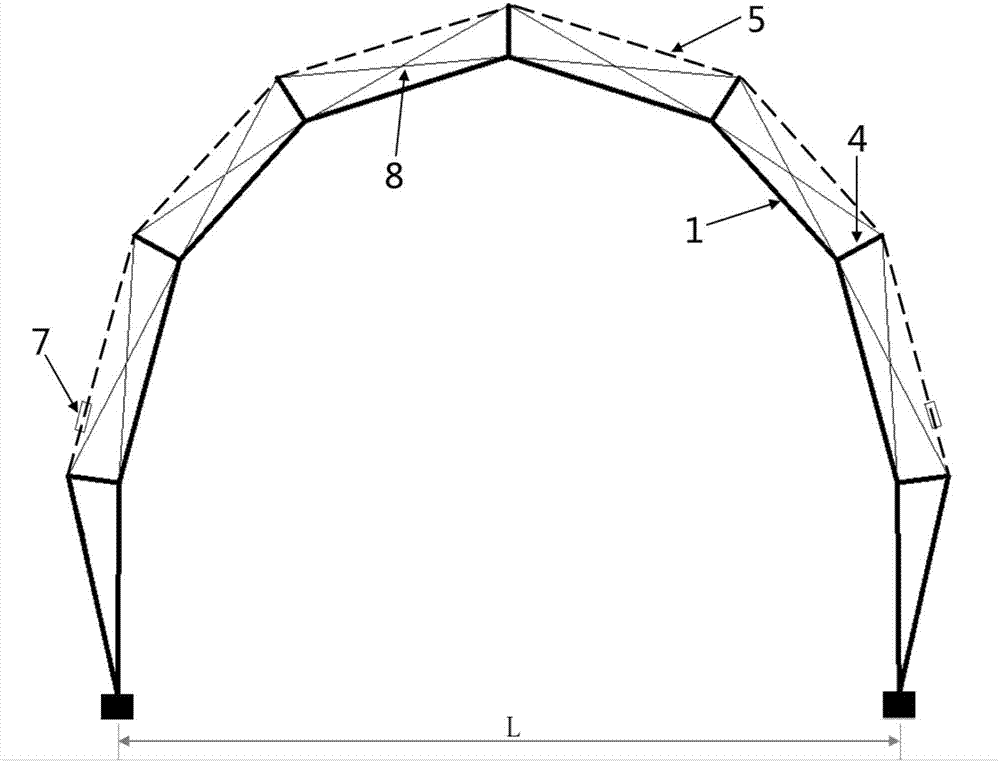

[0029] Such as Figure 1-Figure 4 As shown, the flexible shed of the present invention includes a bottom support structure and an interception net 3, a buffer layer is arranged on the bottom support structure, and the interception net 3 is arranged on the buffer layer. The underlying support structure includes a plurality of support arches 1 and tie rods 2 arranged at intervals. The buffer layer is a space cable truss, and the space cable truss includes a cable column 4 arranged at the intersection of the support arch 1 and the tie rod 2 and a hoop support rope slidably connected to the cable column 4 5 and the vertical support rope 6, the top surface of the space cable support truss is connected to the intercepting net 3. The supporting rope column 4 is provided with a circumferential chute and a longitudinal chute (not shown) that do not interfere with each other, the circumferential support rope 5 is placed in the circumferential chute, and the longitudinal support rope 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com