Machining methods for inner walls of cylinders with thin-walled small half-blind deep holes and thin-walled small full-blind deep holes

A processing method and deep-hole cylinder technology, which are applied in metal processing equipment, reaming devices, manufacturing tools, etc., can solve the problems of thin-walled semi-blind and fully blind small deep-hole cylinder structure processing methods that are not mentioned, to prevent The effect of poor chip evacuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

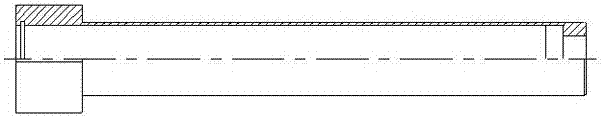

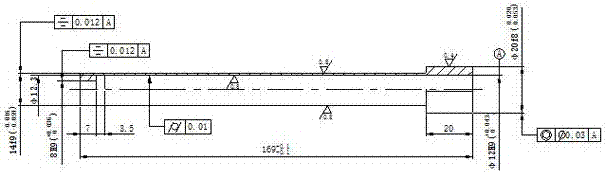

[0090] Such as figure 1 , image 3 As shown, a method for processing the inner wall of a thin-walled semi-blind small deep hole cylinder is carried out according to the following steps:

[0091] The first step, centering and alignment of the machining center

[0092] 1) Select the machining center that processes the inner wall of thin-walled semi-blind and fully blind small deep hole cylinders to ensure that the radial runout and axial runout of the spindle of the machining center are both ≤0.01mm;

[0093] 2) The workpiece is fastened with self-centering three claws, and the outer circle of the workpiece is used as the reference for alignment to ensure that the radial runout of the workpiece is ≤0.01mm;

[0094] The second step is to use non-standard hard alloy internal cooling drill to process the bottom hole

[0095] 1) The machining center mills the upper end face of the workpiece;

[0096] 2) Use the φ19.59 short bottom hole drill to process the guide hole with a dept...

Embodiment 2

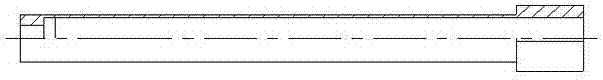

[0115] Such as figure 2 , Figure 4 As shown, a method for processing the inner wall of a thin-walled semi-blind small deep hole cylinder is carried out according to the following steps:

[0116] The first step, centering and alignment of the machining center

[0117] 1) Select the machining center that processes the inner wall of thin-walled semi-blind and fully blind small deep hole cylinders to ensure that the radial runout and axial runout of the spindle of the machining center are both ≤0.01mm;

[0118] 2) The workpiece is fastened with self-centering three claws, and the outer circle of the workpiece is used as the reference for alignment to ensure that the radial runout of the workpiece is ≤0.01mm;

[0119] The second step is to use non-standard hard alloy internal cooling drill to process the bottom hole

[0120] 1) The machining center mills the upper end face of the workpiece;

[0121] 2) Use the φ11.59 short bottom hole drill to process the guide hole with a de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com