Multi-grade seed cotton heavy impurity clearing and separating device

A technology for heavy trash and seed cotton, applied in the field of multi-stage seed cotton heavy trash cleaning device, can solve the problems that seed cotton dyeing reduces seed cotton quality and trash cleaning efficiency, cannot achieve the expected cleaning effect, and the heavy trash cleaning technology is single, etc. The effect of selecting work, low seed cotton loss and high impurity removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

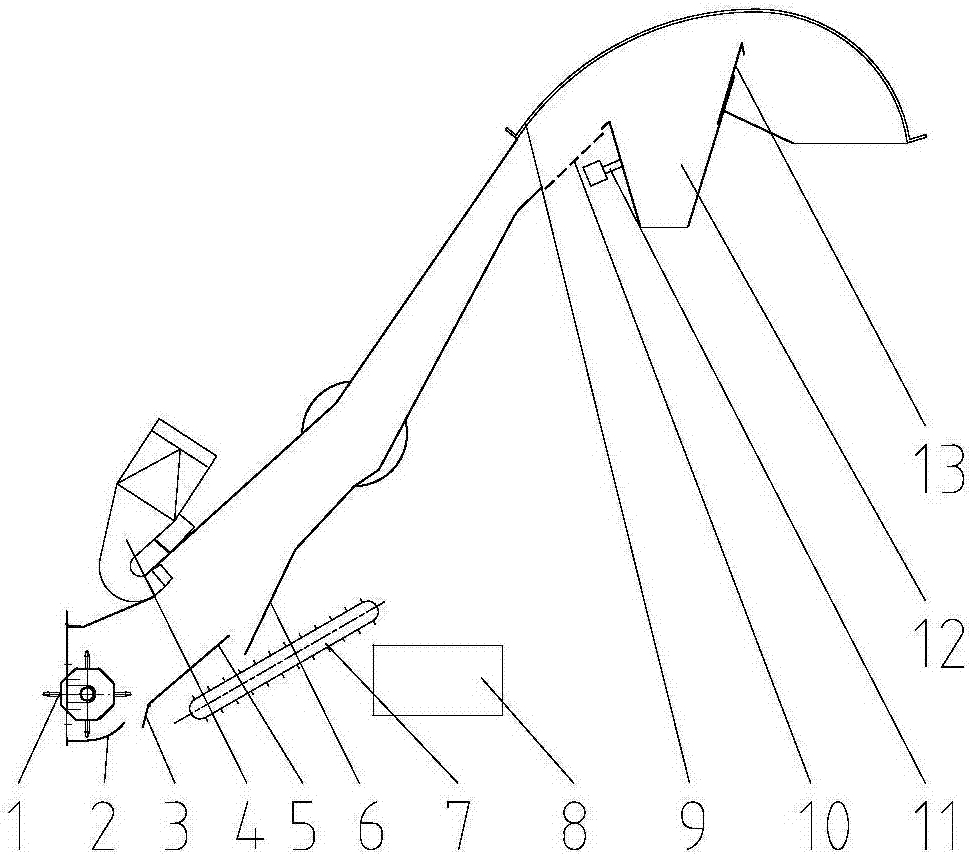

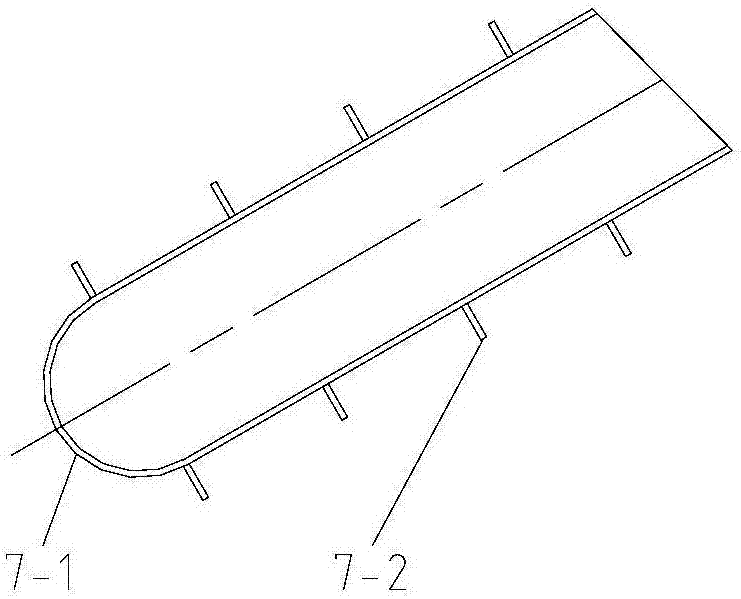

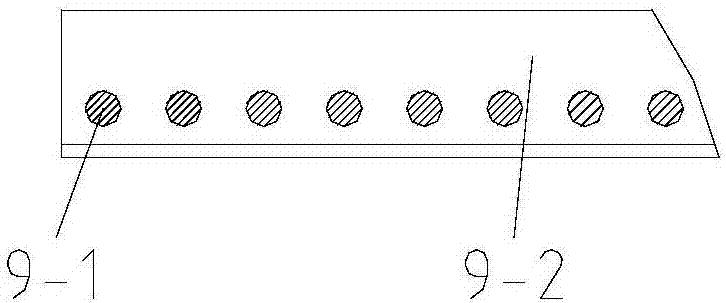

[0023] A kind of multistage seed cotton heavy impurity sorting device of the present embodiment, such as figure 1 , 2 , 3, the multi-stage seed cotton heavy-impurity clearing device is installed on the output end of the colored cotton machine picking platform, and the output end transports the collected seed cotton mass to the multi-stage seed cotton heavy-impurity clearing device, which is characterized in that: multi-stage heavy The miscellaneous sorting device as a whole has a long strip-shaped sequential hierarchy, which successively includes a first-level heavy miscellaneous removal mechanism, a second-level heavy miscellaneous recovery mechanism, a third-level heavy miscellaneous recovery mechanism, and a pipeline connected between the three; the first-level heavy miscellaneous The discharge mechanism includes a cotton picking roller 1 located at the front end of the primary heavy impurity removal mechanism, a primary arc deflector 2 and a primary heavy impurity separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com