Drawer type paper roll box

A paper roll box and drawer type technology, applied in the field of paper roll boxes, can solve the problems of poor cutter safety, pollution, inconvenient operation, etc., and achieve the effects of limiting toilet paper waste, ensuring smooth cutting, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

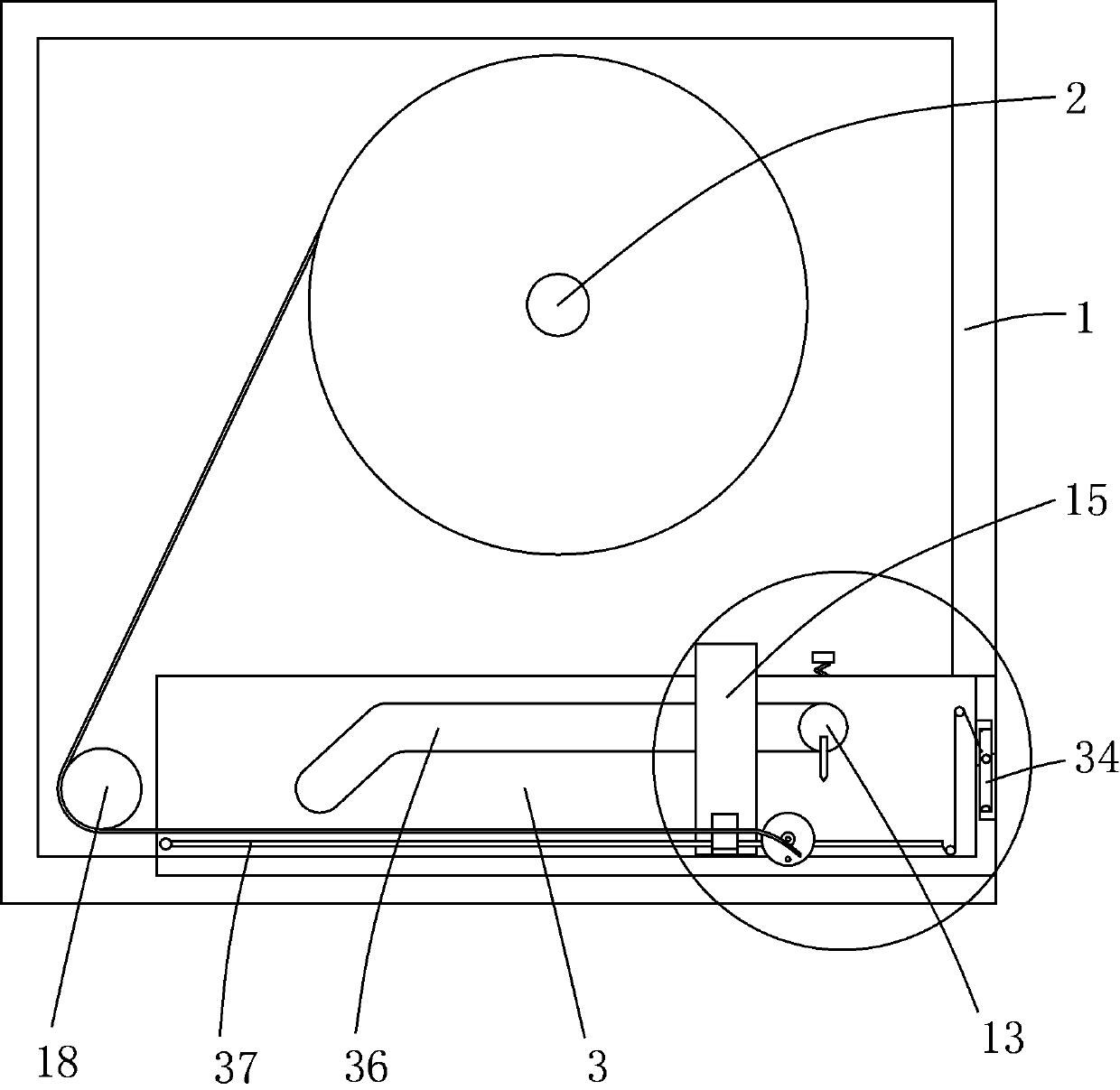

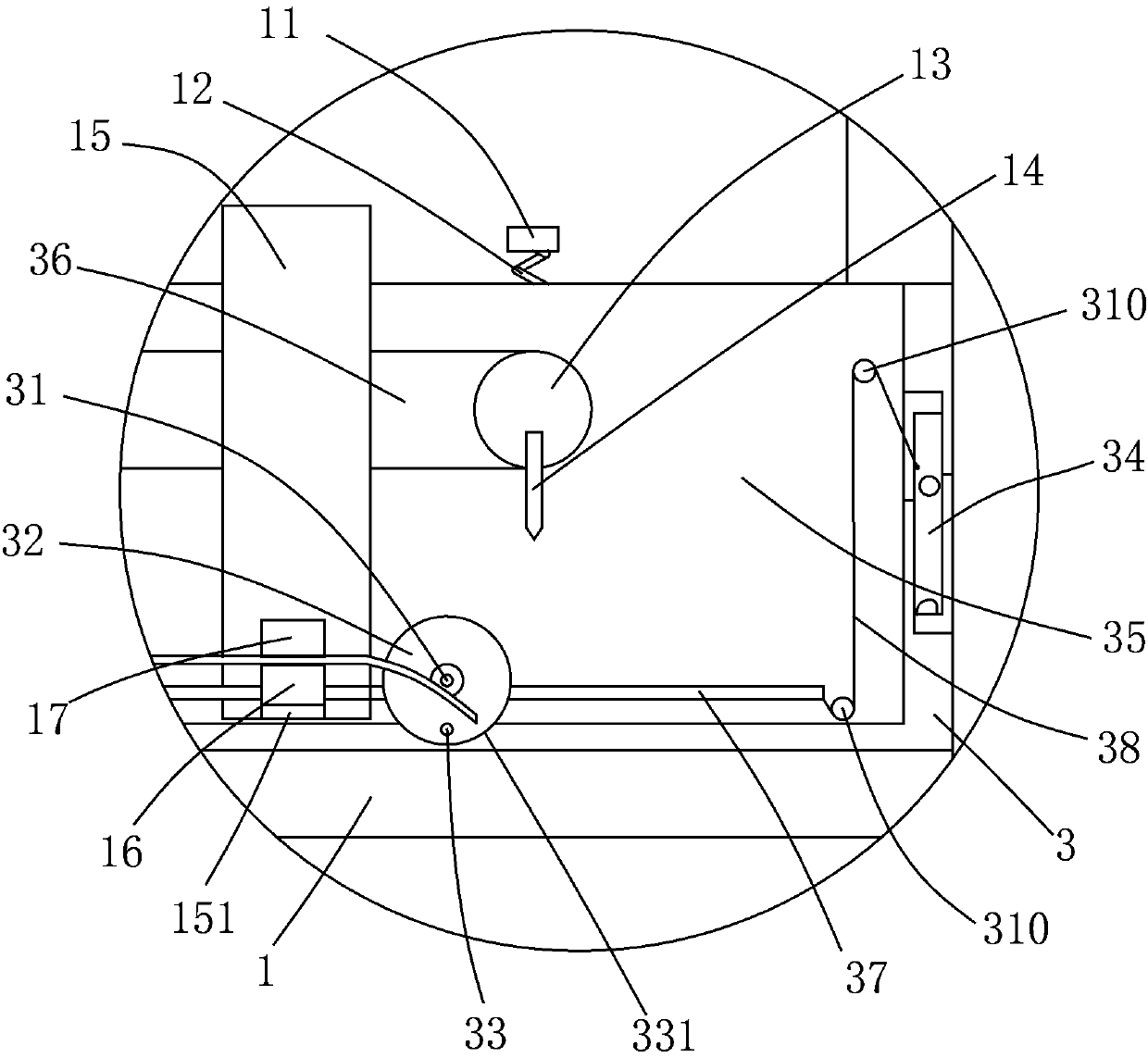

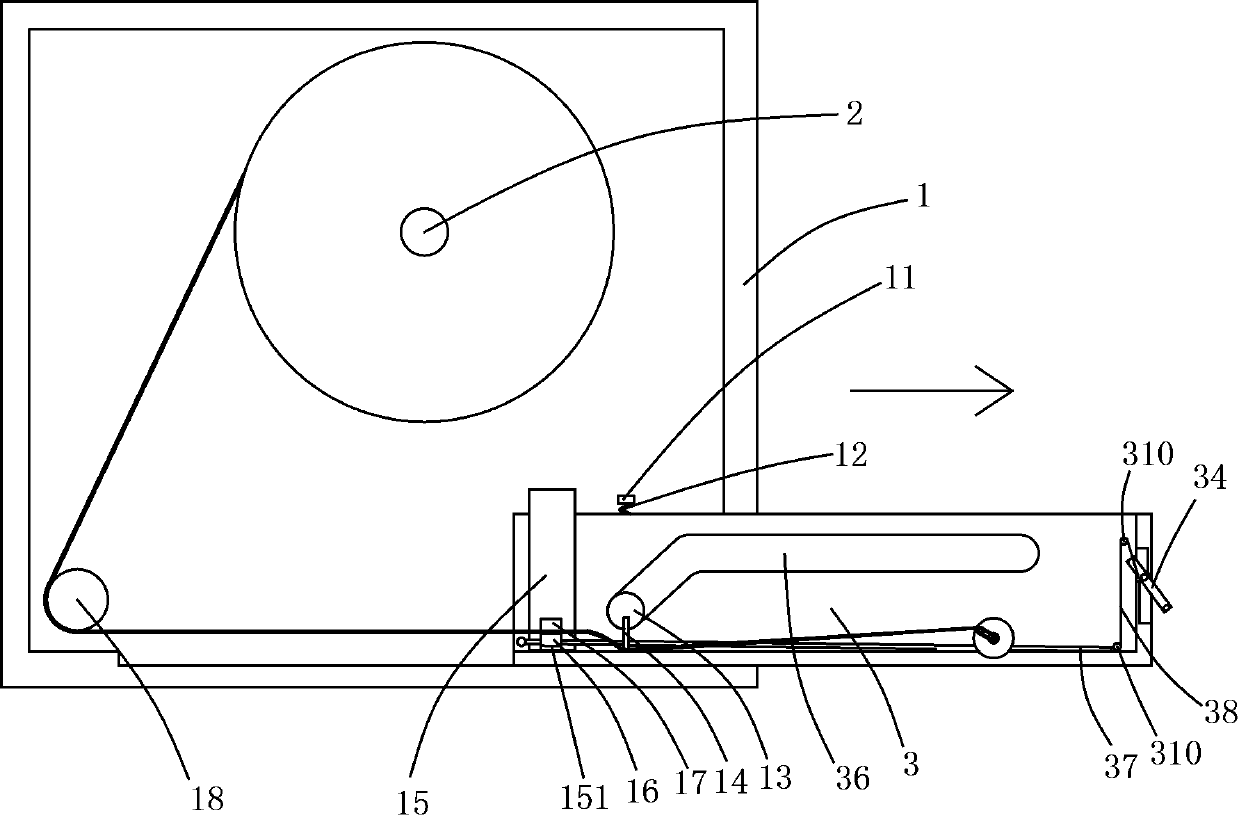

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 6 , a drawer type paper roll box, including a box body 1, a rotating shaft 2 for installing paper rolls is arranged in the box body 1, a drawer 3 is arranged at the bottom of the box body 1, and rolls are installed on both sides of the drawer 3. Around the shaft 31, the winding shaft 31 is connected with a rotating disk 32 through a one-way bearing, the rotating disk 32 is provided with a winding rod 33, and the winding shaft 31 located outside the drawer 3 is fixed with a second A pulley 311, the outside of the drawer 3 is also rotatably provided with a second pulley 39, the first pulley 311 and the second pulley 39 are driven by the belt 4, and the second pulley 39 is coaxially fixed with a gear 391, so The box body 1 is provided with a rack 110 matching the gear 391, guide holes 36 are provided on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com