Rice bran stabilization treatment method and radiofrequency heating device

A stabilization treatment, radio frequency heating technology, applied in food science, food preservation, application, etc., can solve the problems of unsatisfactory enzyme inactivation effect, large equipment footprint, high cost investment, small equipment investment, good heating and uniform heating The effect of sex, high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

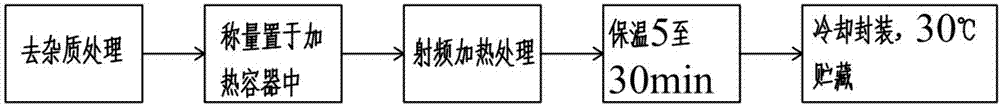

[0036] In Example 1, the rice bran stabilization treatment steps are as follows:

[0037] (1) Remove impurities from fresh rice bran through a 50-mesh sieve, weigh 2kg of rice bran, place it in a glass container, and flatten it to a thickness of 1.5cm; a 50-mesh sieve can remove most impurities, such as rice husk, broken Rice, etc., glass is a thermally stable material, and can ensure the passability of radio frequency, and flattening can also make the processing process more uniform.

[0038] (2) Place the glass container containing rice bran between the two polar plates of the radio frequency heating equipment, fix the distance between the upper and lower plates to 15cm, and set the radio frequency temperature to 120°C through the equipment control panel; the distance and the radio frequency temperature are obtained through experiments The better parameters obtained ensure the effect of protease inactivation, but correspondingly reduce the oil yield.

[0039] (4) Start the ...

Embodiment 2

[0041] In Example 2, the rice bran stabilization treatment steps are as follows:

[0042] (1) Remove impurities from fresh rice bran through a 50-mesh sieve, weigh 1.5kg of rice bran, place it in a plastic container, and flatten it so that the thickness is 1cm; the 50-mesh sieve can remove most impurities, such as rice husk, broken Rice, etc., plastics have good stability below 180 ° C, and are light in weight, which can ensure the passability of radio frequency, and flattening also makes the processing process more uniform.

[0043] (2) Place the plastic container containing rice bran between the two polar plates of the radio frequency heating equipment, fix the distance between the upper and lower plates to 20cm, and set the radio frequency temperature to 90°C through the equipment control panel; the distance and the radio frequency temperature are obtained through experiments Another preferred parameter obtained is that the protease removal effect is worse than that of Exam...

Embodiment 3

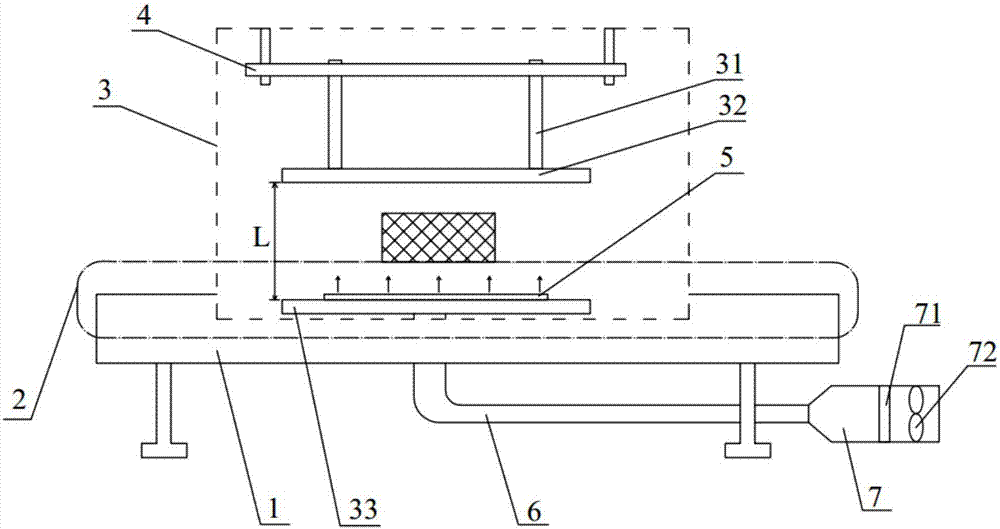

[0046]In Example 3, the radio frequency heating equipment used for rice bran stabilization treatment includes a support platform 1, a conveyor belt 2, a radio frequency unit 3, a hot air distributor 5, a hot air pipeline 6, a hot air generator 7, etc., and the conveyor belt 2 is installed On the support platform 1 , the hot air distributor 5 is placed in the radio frequency unit 3 , and the hot air distributor 5 is connected with the hot air generating device 7 through the hot air pipe 6 . The above structure forms three major systems, namely the conveying system, the radio frequency processing system, and the hot air processing system. These systems are simple in composition and easy to manufacture and install. The radio frequency unit 2 is composed of relatively arranged upper and lower plates 32 / 33, telescopic rods 31, upper frame 4, etc., the upper plate 32 is connected to the upper frame 4 through the telescopic rod 31, and the lower plate 33 is set It is connected with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com