Impermeable anti-skid exposed slope vegetation recovery matrix layer structure

A technology for vegetation restoration and matrix layer, applied in botany equipment and methods, horticulture, fertilization methods, etc., can solve the problems of low-quality stable materials and life expectancy of less than 10 years

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

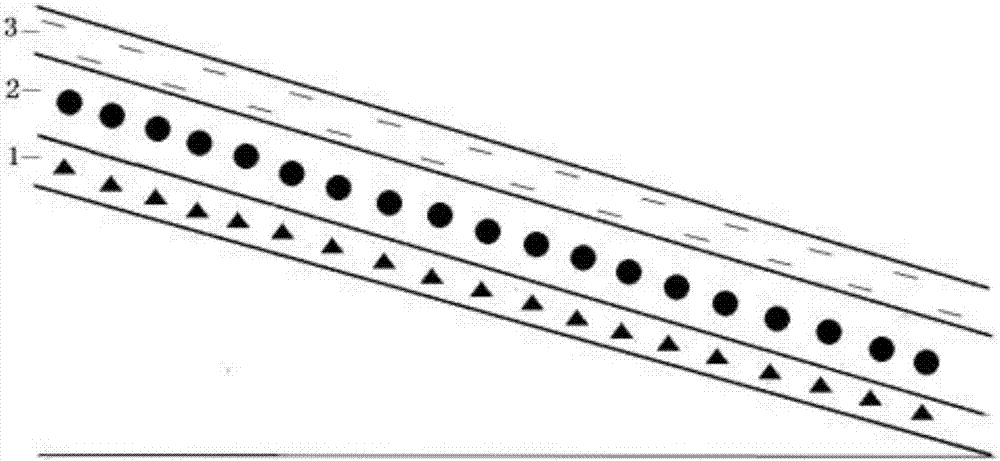

[0038] The structure is:

[0039] 1) Bottom isolation layer: Use clay with a particle size of 0.02mm, and the laying thickness is 5cm;

[0040] 2) Middle drainage layer: Use crushed stone with a particle size of 0.5cm, and the laying thickness is 15cm;

[0041] 3) Surface planting layer: use foreign soil spraying substrate, and the spraying thickness is 10cm.

[0042] Results: Example 2 did not form effective surface runoff under the conditions of a slope of 15° and a precipitation lower than 405mm / h; no water seeped out within 60 minutes under the matrix layer structure.

Embodiment 3

[0044] The structure is:

[0045] 1) Bottom isolation layer: Use clay with a particle size of 0.02mm, and the laying thickness is 5cm;

[0046] 2) Middle drainage layer: Use crushed stone with a particle size of 0.5cm, and the laying thickness is 15cm;

[0047] 3) The surface planting layer: use foreign soil spraying substrate, and the spraying thickness is 15cm.

[0048] Results: Example 3 did not form effective surface runoff under the conditions of a slope of 15° and a precipitation lower than 385 mm / h; no water seeped out within 80 minutes under the matrix layer structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com