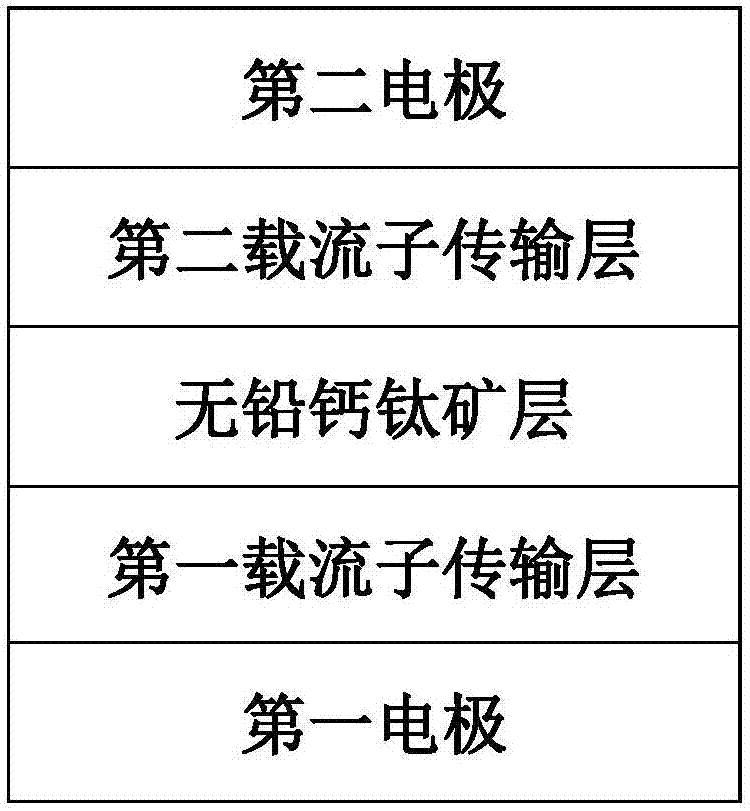

Lead-free perovskite solar cell

A solar cell, lead-free perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of lead element toxicity, high cost of metal electrodes, poor thermal stability of hole transport layers, etc. Sexual problems, reduce expensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] After the glass substrate covered with fluorine-doped tin oxide (FTO) was ultrasonically washed with detergent aqueous solution, deionized water, alcohol and acetone, TiO was wet spin-coated on the substrate. 2 , with a thickness of 100nm.

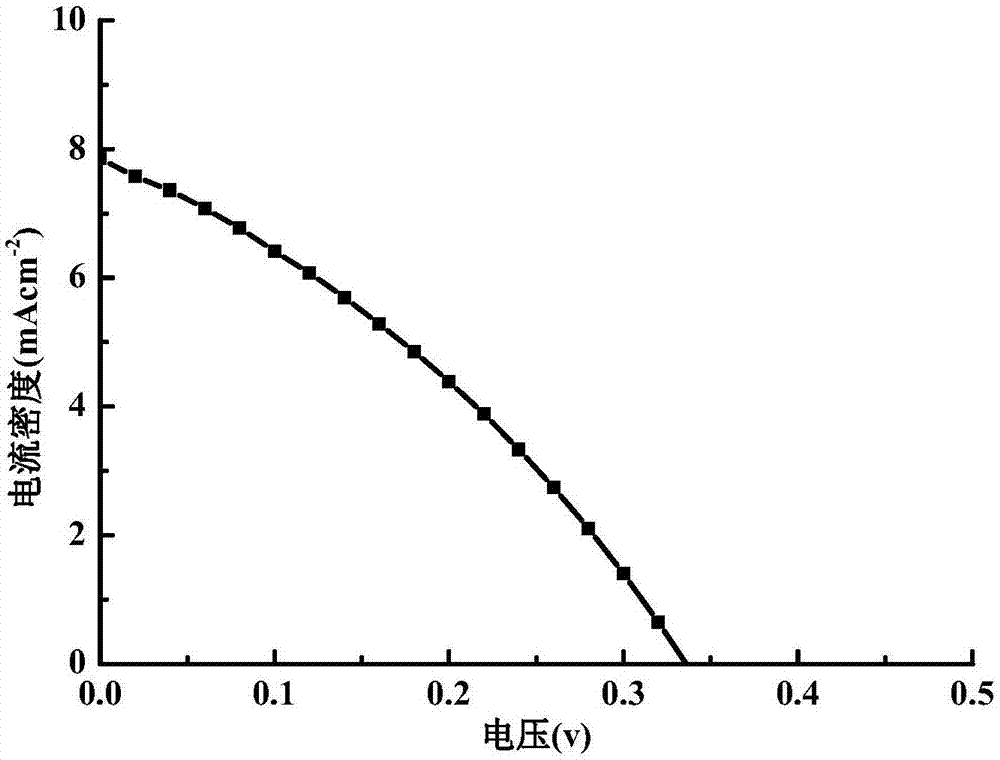

[0034] Then spin-coated CsSnBr with a thickness of 200 nm 3 For the lead-free perovskite layer, after heat treatment at 200 degrees for 20 minutes, put it into a vacuum evaporation machine to thermally evaporate a 60nm molybdenum oxide film and a 150nm aluminum electrode. Such as figure 2 As shown, the prepared solar cell has 7.85 mAcm -2 Short-circuit current, open-circuit voltage of 0.33 V, fill factor of 0.34, and cell efficiency of 0.88%.

Embodiment 2

[0036] After the glass substrate covered with indium tin oxide (ITO) was ultrasonically washed with aqueous detergent solution, deionized water, alcohol and acetone, CuI with a thickness of 150 nm was prepared on the substrate by vacuum evaporation method, and then CuI with a thickness of 100 nm was prepared continuously. SnBr 2 and a 100nm CsBr film, and then prepare a 100nm zinc oxide film by wet method, and finally prepare a 150nm aluminum alloy electrode containing 5% Li in vacuum, and anneal the prepared device at 230 degrees for 60 minutes in an anhydrous and oxygen-free environment 2 React with CsI to generate CsSnIBr 2 Lead-free perovskite layer. The as-prepared solar cell has a 7.56 mAcm -2 Short-circuit current, open-circuit voltage of 0.31V, fill factor of 0.32, and cell efficiency of 0.76%.

[0037]Above, the lead-free perovskite solar cell of the present invention can be known from the result of Example 1, using CsSnBr 3 Perovskite compound, inorganic electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com