Rigidity and stress calculation models of leaf spring torsional vibration damper of diesel engine

A technology of torsional vibration damper and calculation model, which is applied in calculation, computer-aided design, instrument, etc., can solve problems such as application in unfavorable design, complicated stiffness and stress calculation, and low calculation efficiency, and achieves reasonable design and calculation cycle. Short, computationally accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

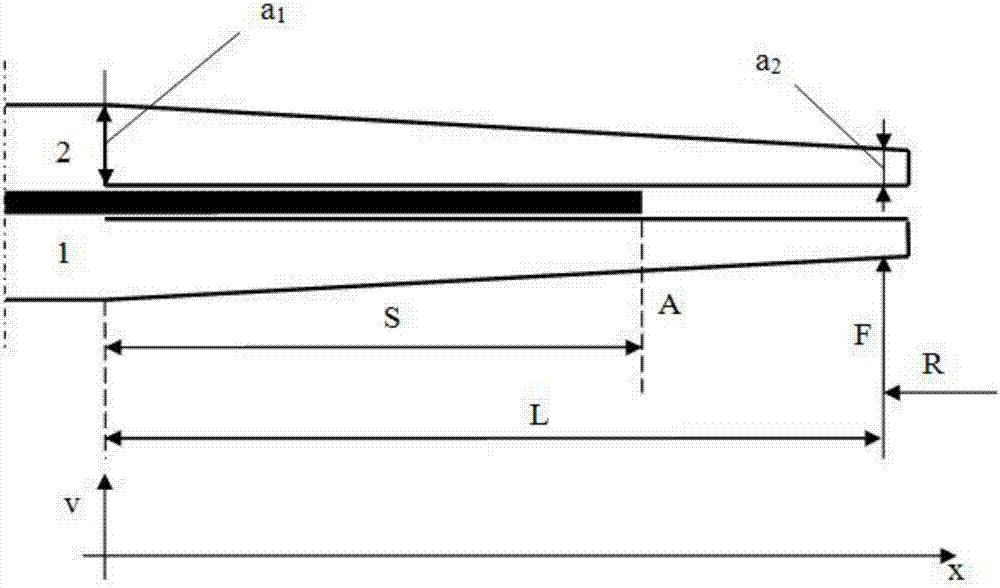

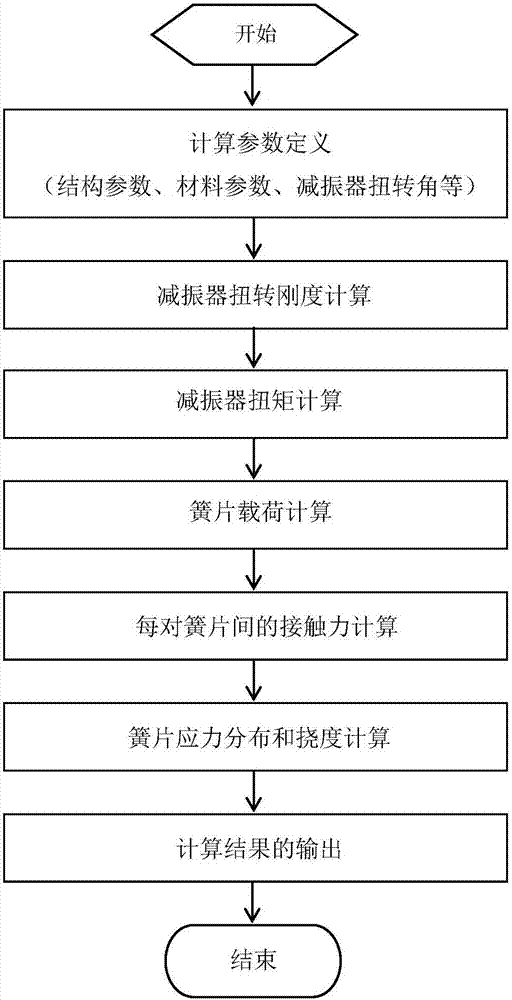

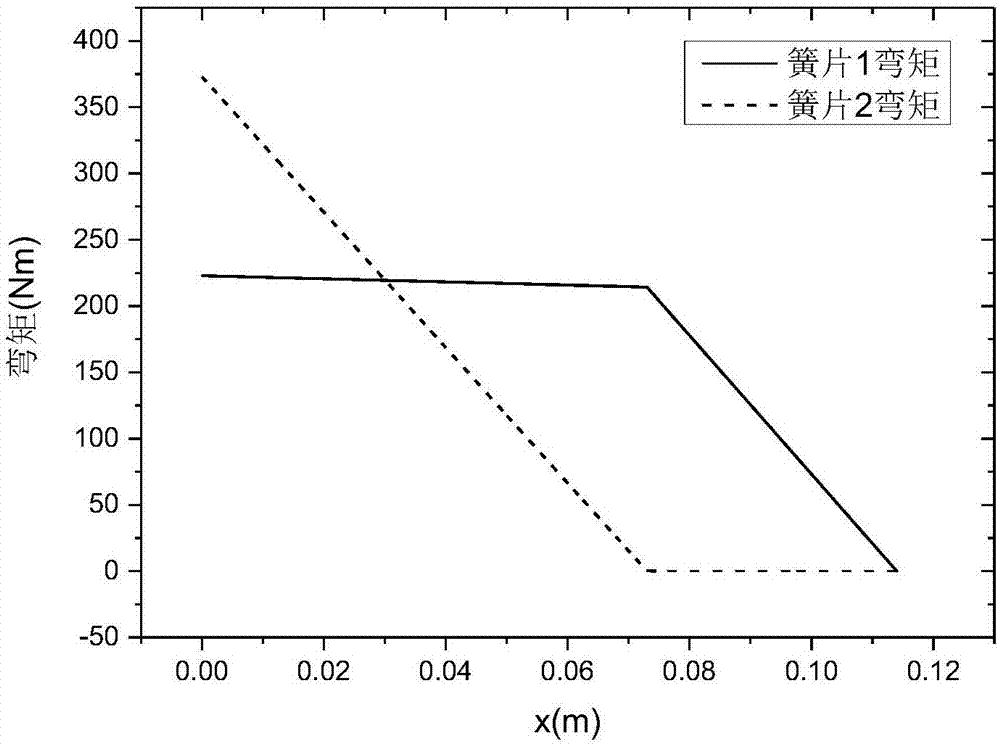

[0047] In the present invention, the formulas in the summary of the invention can be compiled in EXCEL software, and parameters can be input and calculated. An implementation example that the present invention provides, each parameter is set according to table 1, and the stiffness after calculation is 7420.9kN.m / rad; image 3 , the deflection curve see Figure 4 , the bending stress distribution curve is shown in Figure 5 . It can be seen from the deflection image that the two reeds only touch at point A, and the assumed calculation method is correct. It can be seen from the calculation results that the fixed end of the reed ( Figure 6 middle B) and gasket end ( Figure 6 Middle A) is the stress maximum, and the stress values of these two places are listed in Table 2 below.

[0048] Table 1 Shock absorber parameter list

[0049] serial number

variable

value

unit

1

n

24

2

R

0.21

m

3

L

0.114

m

4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com