Calibrating device and calibrating method for rotation center of rotation driving mechanism

A technology of rotating drive mechanism and rotating center, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of long calibration time, high instrument cost, and poor economy, and achieve low cost, high calibration efficiency, and good economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The "horizontal rotation" mentioned in this embodiment means that the rotation axis is in the vertical direction; the "vertical rotation" means that the rotation axis is in the horizontal direction; The center of the formed circle.

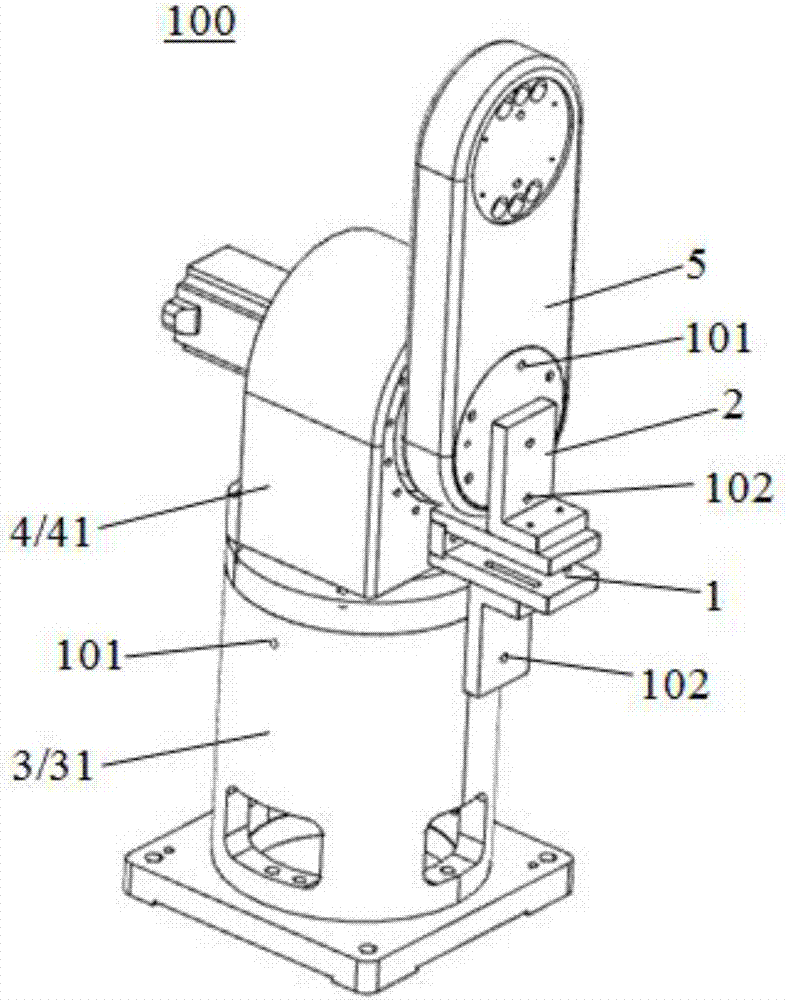

[0030] Please refer to Figure 1-Figure 2 , the present embodiment is a rotation center calibration device 100 for a rotary drive mechanism, which is used to calibrate the center of the rotary drive mechanism, and it includes an installation adjustment plate 1 and a calibration plate 2 fixed on the installation adjustment plate 1, and the installation adjustment plate 1 is subject to the The above-mentioned rotary drive mechanism performs a rotary motion, and the rotary drive mechanism is provided with a plurality of first pin holes 101 in an equiangular ring around its rotation axis, and a plurality of second pin holes 102 are provided on the calibration plate 2, and one of the second pin holes 102 The axis of and the axis of the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com