Three-way tensile pressure-high hydraulic gradient action concrete corrosion test device and method

A test device and concrete technology, which is applied in the field of simulation test, can solve the problems of studying the chemical erosion characteristics of hydraulic concrete, and achieve the effects of small space occupation, improved load stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with embodiment the present invention will be further described.

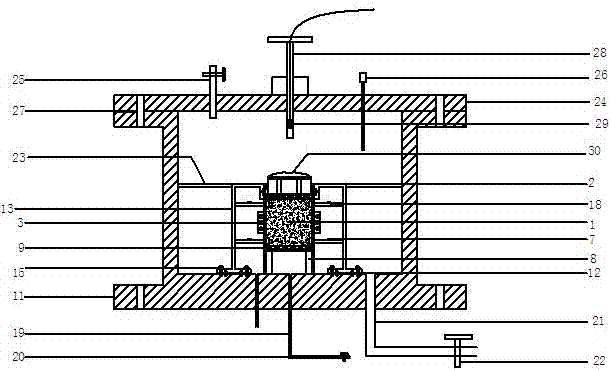

[0052] Such as Figure 1-3 Shown, a kind of three-way tensile pressure-high hydraulic gradient effect concrete dissolution test device, comprises solution chamber, sealing chamber and dissolution chamber, and described solution chamber is provided with sealing chamber, and sealing chamber is provided with dissolution chamber;

[0053] Described dissolution chamber comprises concrete standard specimen 1 and is respectively positioned at its top and bottom permeable stone 10 and bottom permeable stone 9,

[0054] Described sealing chamber comprises sealing chamber steel plate 13, and the bottom of sealing chamber steel plate 13 is fixed on the bottom surface in the solution chamber, and the outer wall top of described sealing chamber steel plate 13 connects the solution indoor sidewall by sealing chamber bracket 23;

[0055] The top of the solution chamber is provided with a water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com