Dredging robot and application method thereof

A technology of robots and silt, applied in the direction of earth movers/excavators, waterway systems, water supply devices, etc., can solve problems such as unsatisfactory cleaning of hidden dangers, affecting people's normal travel and life, and failure to perform normal functions. To achieve the realization of intelligent automatic operation, high-quality application effect, and ensure the effect of normal progress or retrogression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described below with reference to the accompanying drawings.

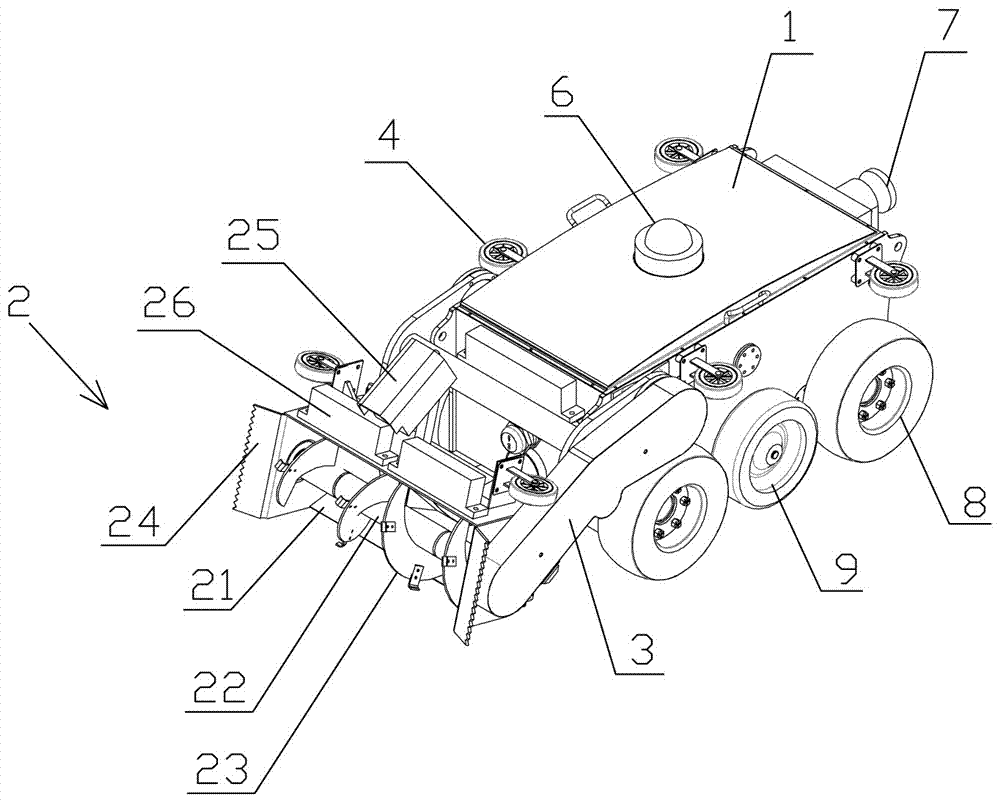

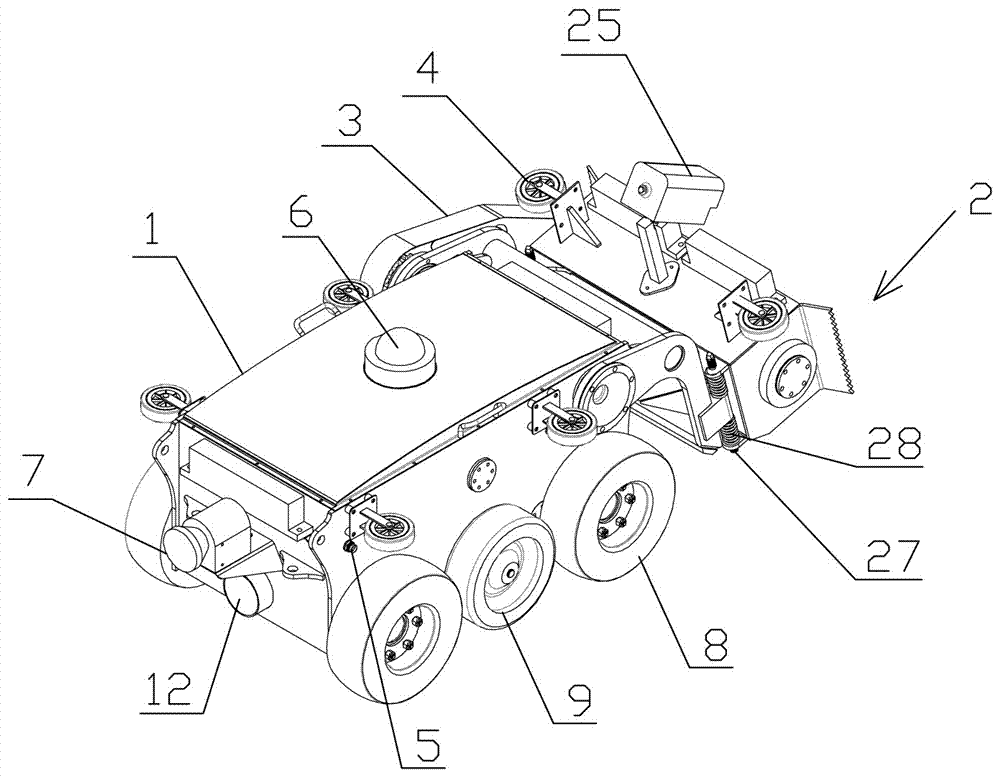

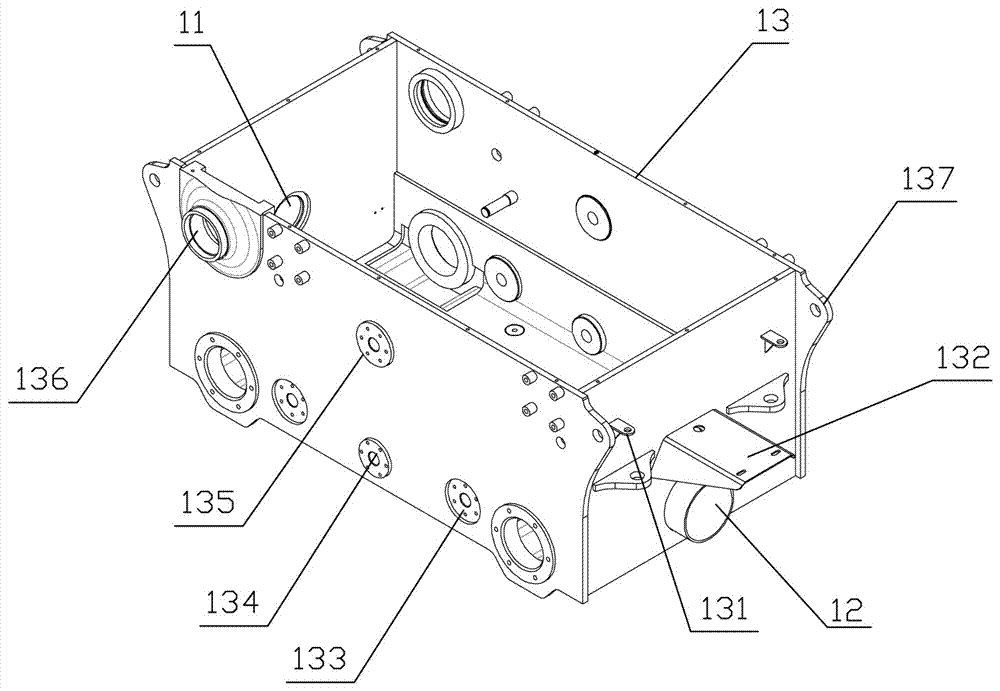

[0038] Such as Figure 1 to Figure 5As shown, a dredging robot includes a car body 1, a working device 2 for crushing and collecting sludge, and a lifting mechanism 3 for adjusting the working installation position of the working device 2. The lifting mechanism 3 Installed at the front end of the car body 1, the working device 2 is movably mounted on the lifting mechanism 3; the front side wall of the car body 1 is provided with a mud inlet 11, the car body 1 is provided with a conveying pipe 12 on the rear end side wall, and the interior of the car body 1 is provided with a penetrating conveying pipe (not shown in the figure due to the viewing angle), and the front end of the penetrating conveying pipe communicates with the mud inlet 11 , the rear end of the penetrating conveying pipe communicates with the conveying pipe 12, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com