Nano modified melt-blown nonwoven fabric material and manufacturing method thereof

A melt-blown non-woven fabric and nano-modification technology, which is applied in the field of filter materials, can solve the problems of poor mechanical properties, low strength, and poor wear resistance of melt-blown fabrics, and achieve high-strength mechanical properties, good mechanical properties, and mechanical properties. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

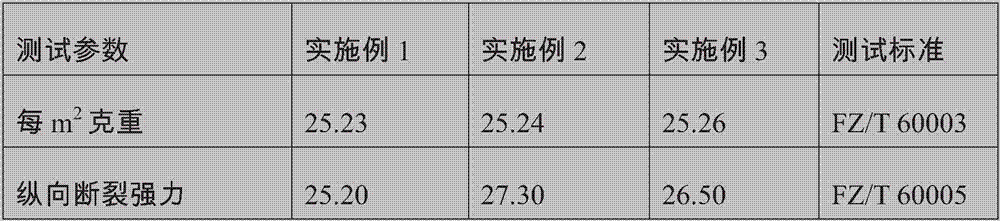

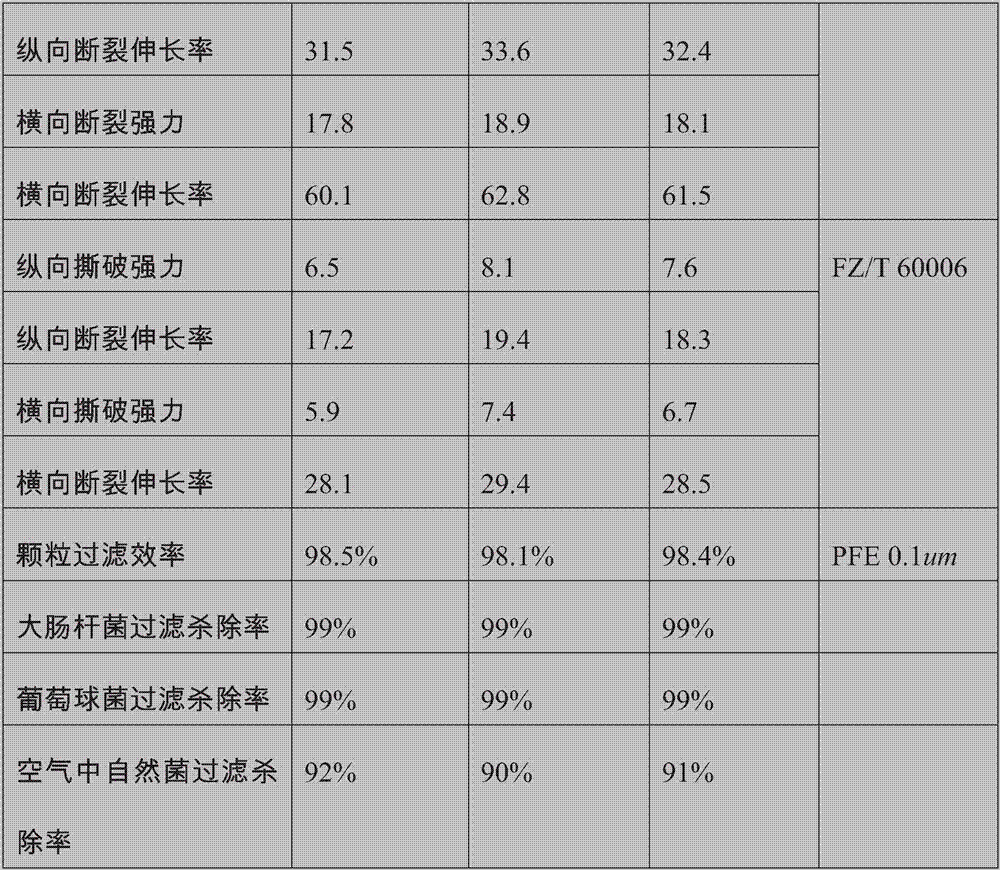

Examples

Embodiment 1

[0051] 1) Selecting nano silicon dioxide with a particle size of 20-25nm and titanium dioxide with a particle size of 5-10nm; drying at a temperature of 120°C to remove moisture;

[0052] 2) Uniformly dissolving nano-silica and nano-titanium dioxide in toluene at a mass fraction of 1% and 4% respectively, and then adding 0.2% mass fraction of a coupling agent;

[0053] 3) Use ultrasonic mixing and oscillation for 20 minutes;

[0054] 4) Put the mixed solution in a water bath reflux reaction device, react for 180 minutes, and the temperature is 95°C;

[0055] 5) washing with absolute ethanol and drying after suction filtration to obtain modified nano-silica and nano-titanium dioxide;

[0056] 6) Mix the modified nano-silica and nano-titanium dioxide mixture with polypropylene chips at a mass percentage of 5%, and make polypropylene melt-blown non-woven fabrics through melt-blown nonwoven molding equipment;

[0057] 7) Electret treatment is carried out on the non-woven fabric ...

Embodiment 2

[0060] 1) select nano silicon dioxide with a particle size of 20-25nm, and titanium dioxide with a particle size of 5-10nm; dry at a temperature of 100°C to remove moisture;

[0061] 2) Uniformly dissolving nano silicon dioxide and nano titanium dioxide in toluene at a mass fraction of 6% and 1% respectively, and then adding 0.3% mass fraction of a coupling agent;

[0062] 3) Use ultrasonic mixing and oscillation for 20 minutes;

[0063] 4) Put the mixed solution in a water bath reflux reaction device, react for 180 minutes, and the temperature is 95°C;

[0064] 5) Clean and filter with absolute ethanol and then dry;

[0065] 6) Mix the modified nano silicon dioxide and nano titanium dioxide mixture with polypropylene slices at a mass percentage of 8%, and make polypropylene melt blown nonwoven fabric through melt blown nonwoven forming equipment;

[0066] 7) Electret treatment is carried out on the non-woven fabric through a corona electret process to obtain a nano-modified...

Embodiment 3

[0068] 1) select nano silicon dioxide with a particle size of 20-25nm, and titanium dioxide with a particle size of 5-10nm; dry at a temperature of 140°C to remove moisture;

[0069] 2) Uniformly dissolving nano-silica and nano-titanium dioxide in toluene at a mass fraction of 3% and 2%, respectively, and then adding a coupling agent of 0.1% mass fraction;

[0070] 3) Use ultrasonic mixing and oscillation for 40 minutes;

[0071] 4) Put the mixed solution in a water bath reflux reaction device, and react for 200 minutes at a temperature of 105°C;

[0072] 5) Clean and filter with absolute ethanol and then dry;

[0073] 6) Mix the modified nano silicon dioxide and nano titanium dioxide mixture with polypropylene slices at a mass percentage of 4%, and make polypropylene melt blown nonwoven fabric through melt blown nonwoven forming equipment;

[0074] 7) Electret treatment is carried out on the non-woven fabric through a corona electret process to obtain a nano-modified melt-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com