Preparation method of 4-hydroxy ciclosporin

A technology of hydroxycyclosporine and cyclosporine, which is applied in the field of organic synthesis and can solve problems such as difficult industrial production, low yield, and difficult purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

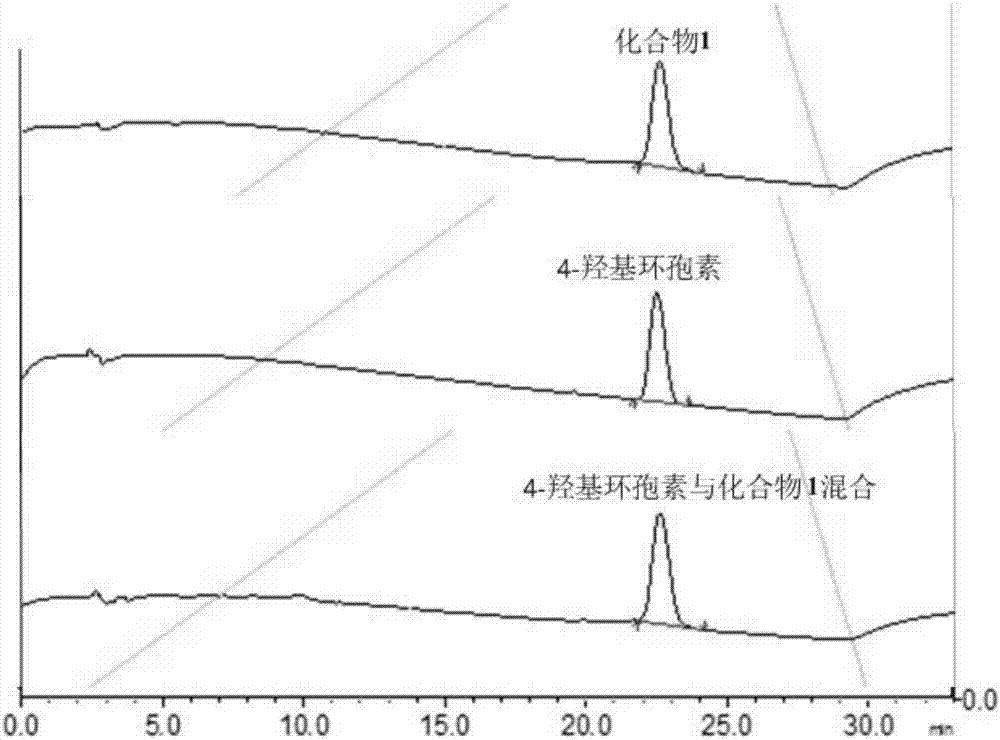

Image

Examples

preparation example Construction

[0049] Concrete, the preparation method of 4-hydroxycyclosporin comprises the following steps:

[0050] Step 1. Dissolve compound 2 and the first reactant in the first organic solvent at -20°C to 35°C (preferably in ice bath), and then add 3- Chloro-2-methylpropene, then heated to 58°C-62°C (preferably 60°C) and fully reacted (reaction time is preferably 2h), then added water and adjusted the pH to 7 with an acidic regulator, purified after sufficient reaction to obtain Compound 3.

[0051] The first reactant is selected from NaH, KH, K 2 CO and Cs 2 CO 3 at least one of the .

[0052] The acid regulator is hydrochloric acid, citric acid, sulfuric acid or fluoboric acid. Preferably, the acid regulator is hydrochloric acid (with a concentration of 0.5 mol / L-12 mol / L).

[0053] The structural formulas of compound 2, 3-chloro-2-methylpropene and compound 3 are as follows,

[0054] Compound 2: Compound 3:

[0055] In step 1, NaH and 3-chloro-2-methylpropene were added ...

Embodiment 1

[0137] Step 1. Compound 2 (diethyl acetylaminomalonate, 217.1 g, 1.0 mol) was dissolved in 2.0 L of DMF, and then NaH (60 wt% dissolved in kerosene, 48.0 g, 1.2 mol) was added. 3-Chloro-2-methylpropene (108.7 g, 117.5 mL, 1.2 mol) was then added under ice cooling, and the addition was completed within 30 min. The temperature was then heated to 60°C and maintained for 2 hours. Water (2.0 L) was then added, and the pH of the solution was adjusted to 7 with 1.0 mol / L HCl. At room temperature, reacted for 12 h, the precipitated white solid was collected by filtration, washed with distilled water (2×1 L), and finally dried in a vacuum oven to obtain compound 3 (247.0 g, 91%).

[0138] Step 2. Dissolve compound 3 (108.6 g, 0.5 mol) in 0.5 L of ethanol, add 0.5 L of 3.0 M NaOH aqueous solution, react under reflux for 3 h, then remove ethanol, and then adjust the pH with concentrated hydrochloric acid (12 mol / L) The value was 7, refluxed for 2h, and then the pH value of the solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com