High-speed molding device and preparation method for conductive foam cotton

A technology of conductive foam and molding equipment, which is applied in the direction of electrical components, magnetic field/electric field shielding, local shielding, etc. It can solve the problems of inability to seal the conductive cloth, unguaranteed quality, low production efficiency, etc., and achieve convenience Adhesive backing, saving labor, improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

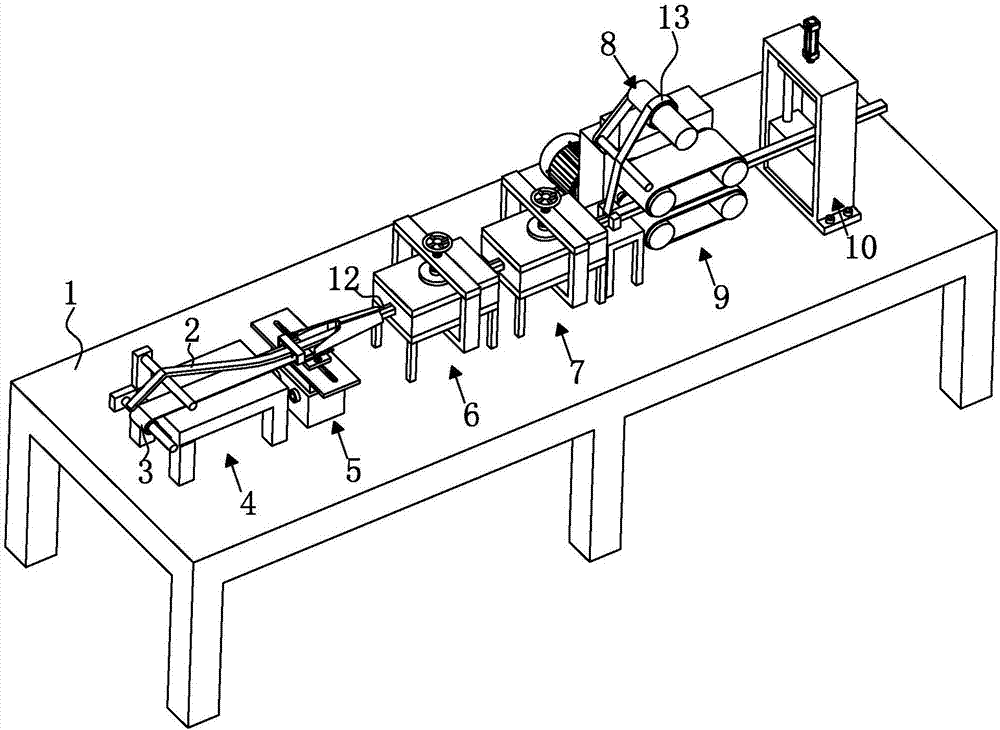

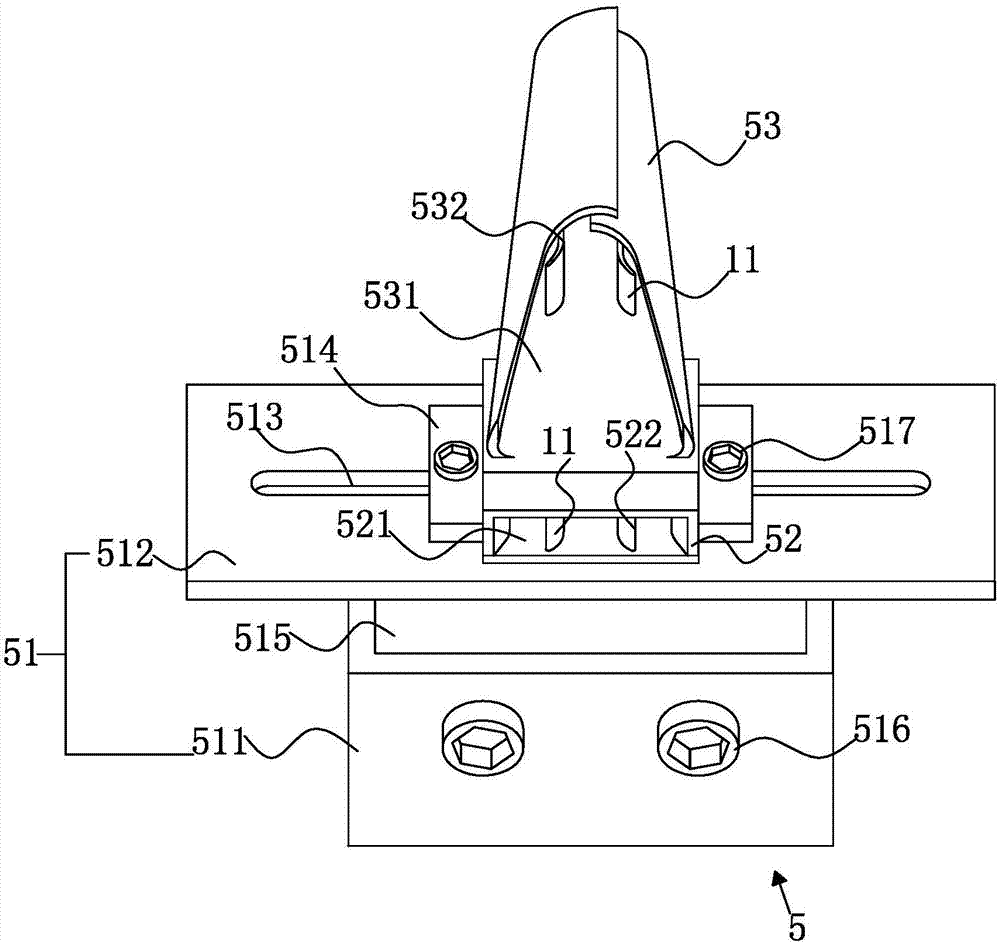

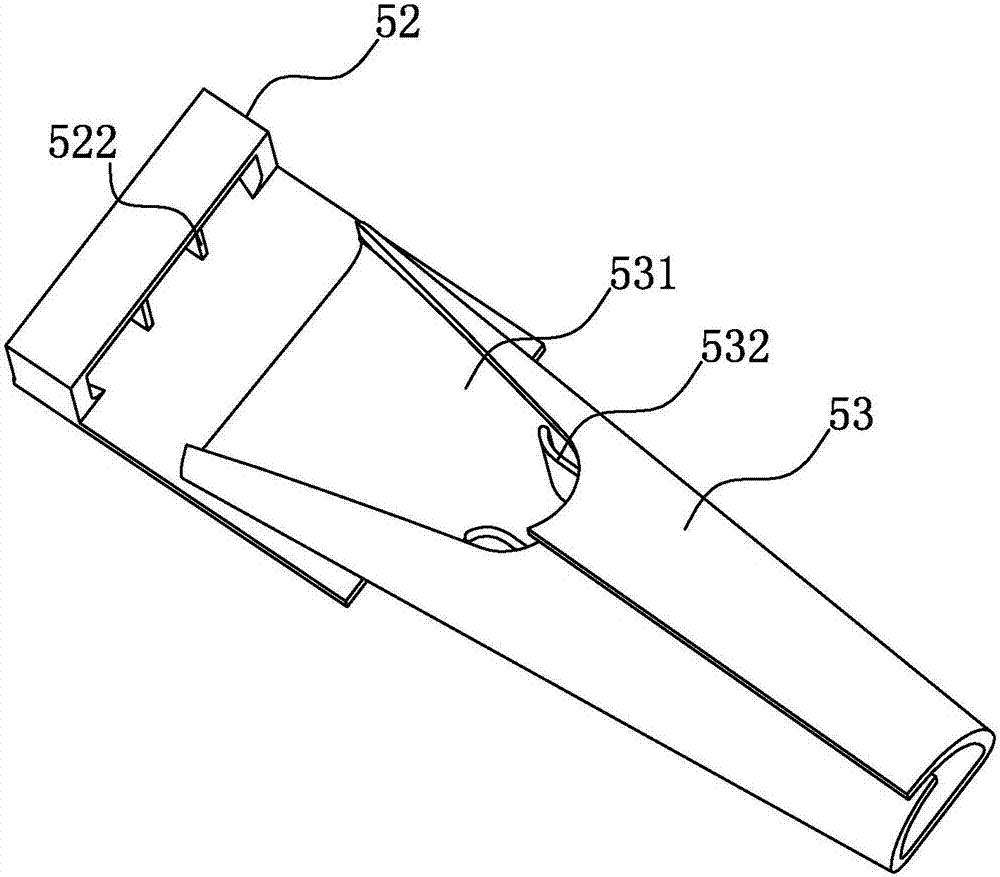

[0034] Please refer to Figure 1-Figure 6 , the structure of a high-speed molding equipment for conductive foam according to an embodiment of the present invention will be specifically described below.

[0035] like figure 1 As shown, a high-speed molding equipment for conductive foam according to an embodiment of the present invention includes: a workbench 1; a first feeding station, an overmolding station, a heating station, and a cooling station are arranged on the workbench 1 position, the second feeding station, the adhesive traction station and the cutting station; the first feeding station is provided with a first feeding device 4 for providing sponge strips 2 and conductive cloth 3; overmolding The station is provided with an overmolding device 5 for making the conductive cloth 3 wrap the sponge strip 2 to form the first processed body; The hot-melt glue melts so that the conductive cloth 3 and the sponge strip 2 are pasted by hot-melt glue to form a heating device 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com