Plate double-surface synchronous polishing device

A polishing device and plate technology, applied in polishing machine tools, grinding/polishing equipment, grinding machines, etc., can solve the problems of plate deformation, limited position limit, uneven plate polishing, etc. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

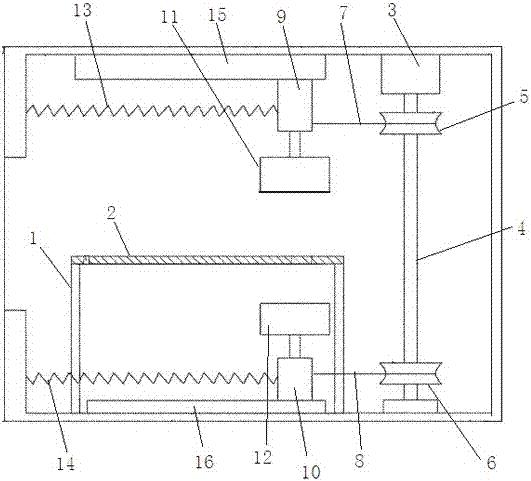

[0029] In order to prevent impurities from entering between the polishing head and the plate during the polishing process and destroy the polishing effect, the present invention also includes a closed casing, the plate support 1, the fixed end of the tension spring, the driving motor 3 and the mounting seat 15 (16) of the polishing mechanism are all fixed. on the closed case.

[0030] The mounting seat in the polishing mechanism is a fixed strip guide rail, the length direction of the strip guide rail is parallel to the telescopic direction of the extension spring, and the polishing machine is slidably connected to the strip guide rail. Such as figure 1 , The strip guide rail is fixed on the closed shell.

[0031] In order to facilitate the replacement of the plate to be polished, the polishing mechanism also includes a lifting drive mechanism, the lifting drive mechanism includes a telescopic rod, and the end of the telescopic rod is fixedly connected to the polishing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com