Integrated ultrafiltration water purification device

A water purification device and packaged technology, which is applied in ultrafiltration, water pollutants, water/sewage treatment, etc., can solve problems such as different sizes, sewage treatment, and increased investment costs in the entire life cycle of ultrafiltration membrane systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

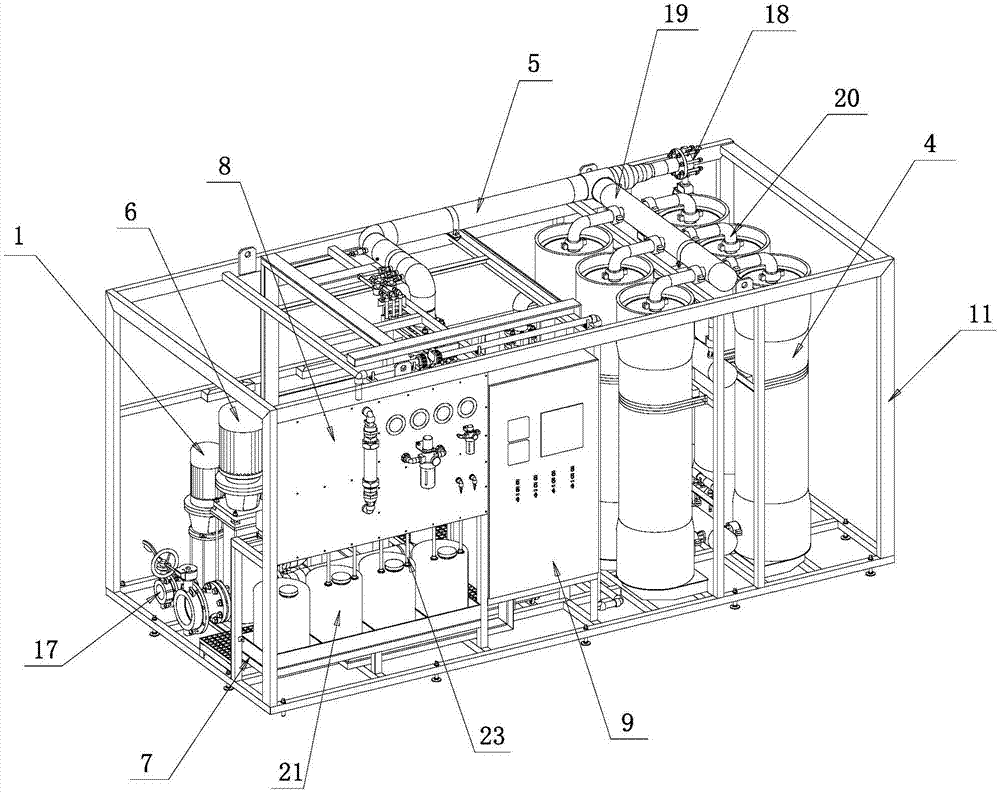

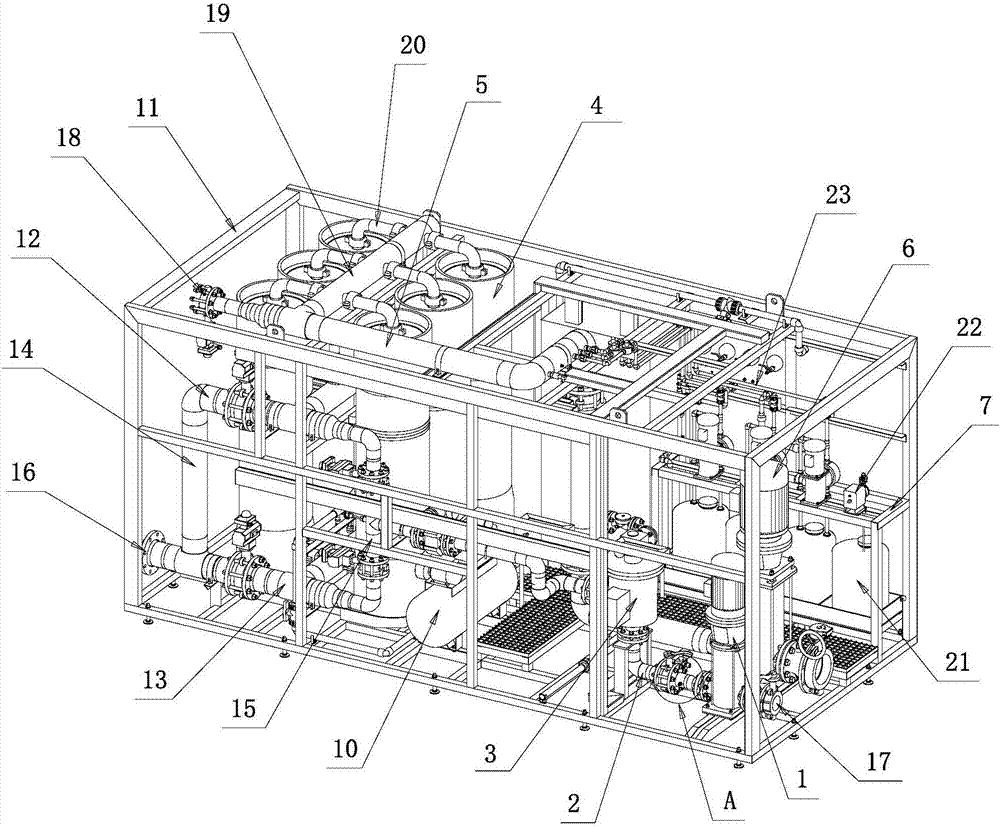

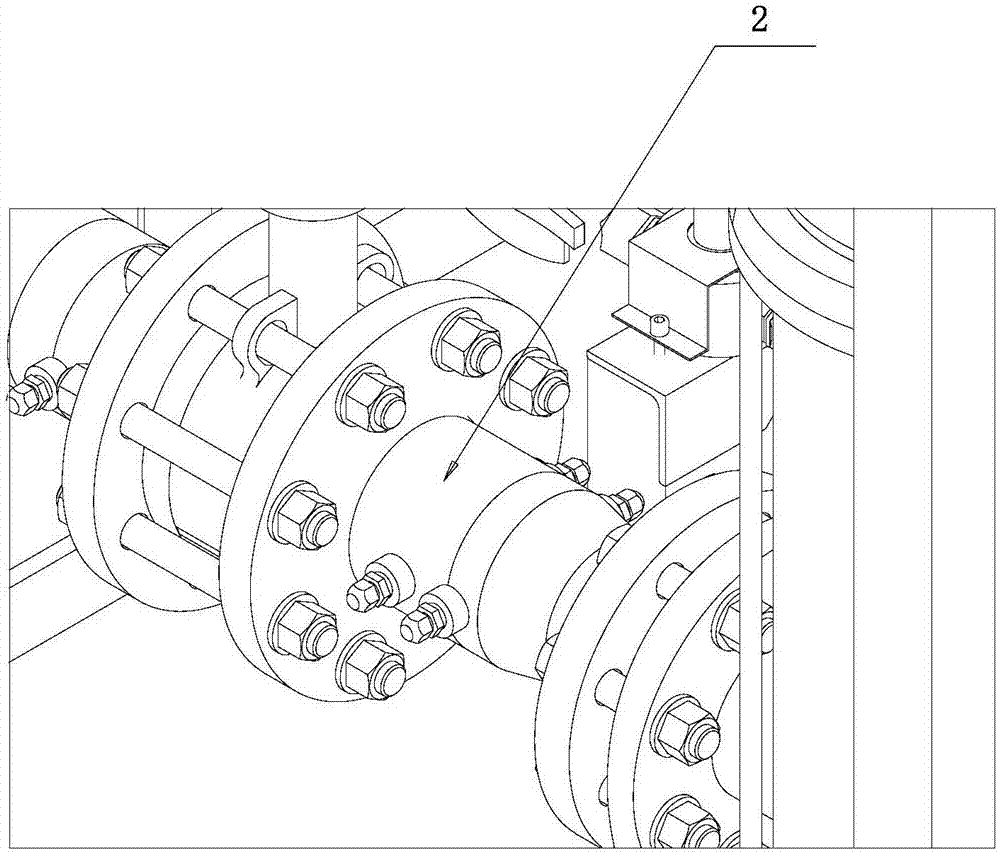

[0028] Below in conjunction with the drawings Figure 1 to Figure 3 The integrated ultrafiltration water purifier of the present invention will be described in further detail.

[0029] A collection type ultrafiltration water purification device of the present invention, please refer to Figure 1 to Figure 3 Related figures in the middle, including the container rack 11 and the ultrafiltration membrane module installed inside the container rack 11, the water inlet system, the water production system, the backwash system, the online cleaning and filtering device 3. The ultrafiltration membrane membrane set includes at least one vertical ultrafiltration membrane pressure vessel 4, and at least ten membrane filaments are arranged in plumb line in the ultrafiltration membrane pressure vessel 4. The front end of the water inlet system is in adjustable flow communication with the raw water arranged outside the container rack 11, and the back end of the water inlet system is in flow adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com