Cutting device for power cable stripping

A technology of power cable and cutting device, which is applied in the direction of cable installation device, cable installation, dismantling/armored cable equipment, etc., to prevent deviation of cutting position, improve stability, and improve portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

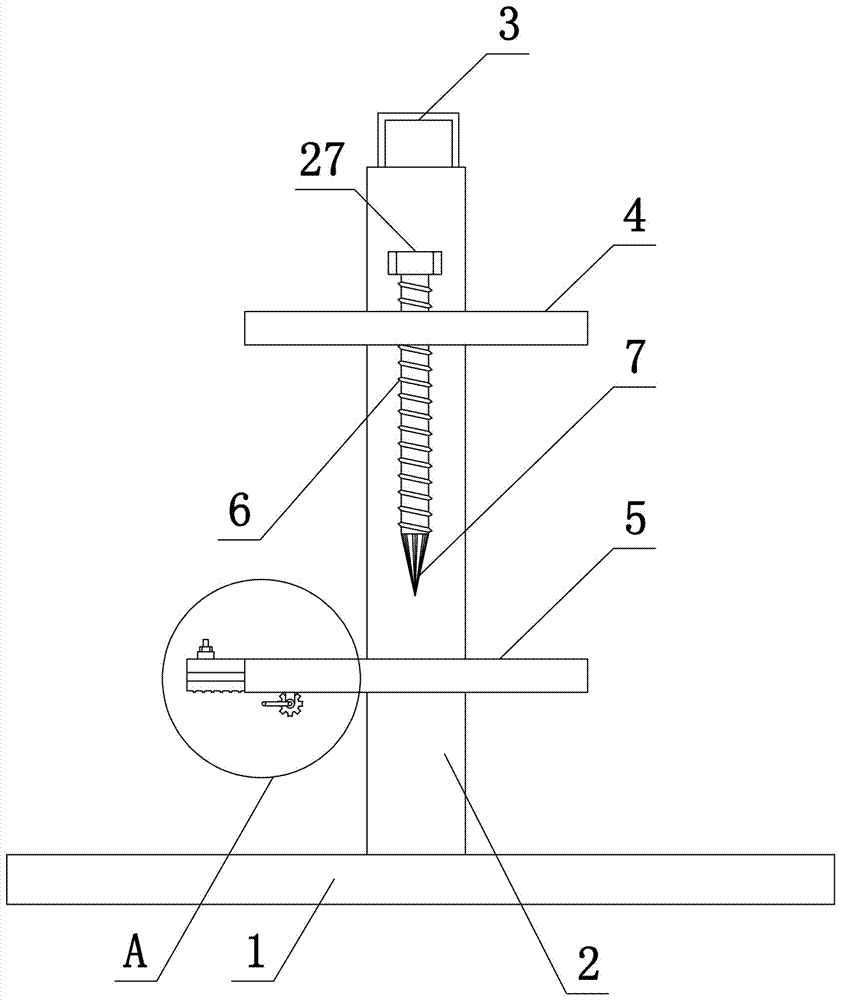

[0034] Such as Figure 1-4 As shown, the present invention includes a support base 1, the upper end surface of the support base 1 is fixedly connected to the support arm 2, the upper end surface of the support arm 2 is fixedly connected to the handle 3, and the support arm 2 is fixedly connected to the upper support plate 4 and the lower support plate 5 in the horizontal direction. , the upper support plate 4 is provided with a threaded hole in the vertical direction, the threaded hole is internally threaded to connect the first screw 6, the upper end of the first screw 6 is integrally formed with a hexagonal nut 27, the lower end of the first screw 6 is welded with an insulating skin cutter 7, and the insulating skin Cutting knife 7 is a hexagonal pyramid structure, wherein the edge of the hexagonal pyramid is a blade;

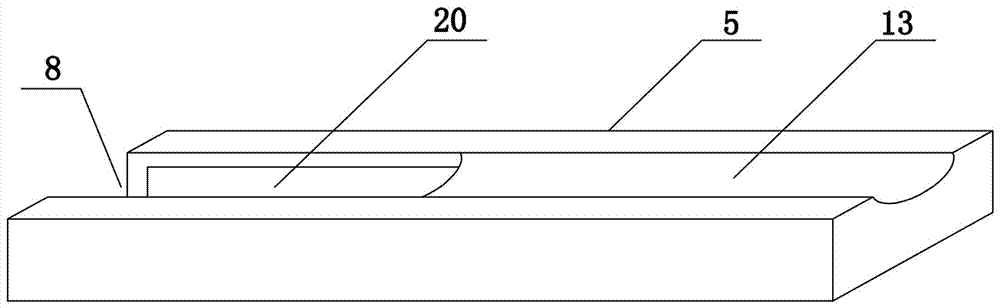

[0035]The left end of the lower support plate 5 is provided with an elongated groove 8, and the spur rack 9 is slidably connected in the elongated groove 8, ...

Embodiment 2

[0037] Such as Figure 1-5 As shown, the present invention comprises a support base 1, a support arm 2 is arranged on the upper end surface of the support base 1, a handle 3 is arranged on the upper end surface of the support arm 2, an upper support plate 4 and a lower support plate 5 in the horizontal direction are arranged on the support arm 2, and the upper support plate 4. Provide a threaded hole in the vertical direction, the threaded hole is internally threaded to connect the first screw rod 6, the upper end of the first screw rod 6 is integrally formed with a hexagonal nut 27, and the lower end of the first screw rod 6 is provided with an insulating skin cutting knife 7, and the insulating skin cutting knife 7 is Hexagonal pyramid structure, in which the edge of the hexagonal pyramid is the blade;

[0038] The left end of the lower support plate 5 is provided with an elongated groove 8, and the spur rack 9 is slidably connected in the elongated groove 8, and the gear 10...

Embodiment 3

[0041] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 6 As shown, the upper end surface of the spur rack 9 is provided with a first wire groove 28, and the lower end surface of the wire pressure plate 16 is provided with a second wire groove 29. This structure effectively fits the outer wall of the cable wire by installing two wire grooves on the spur rack 9. Fixed to prevent the problem of deformation of the cable wires during the clamping and fixing process of the cable wires by the wire pressing plate 16 and the spur rack 9, especially when used on a steel strand cable, it can effectively prevent the loosening of the ends of the steel strand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com