Magnetic fluid sealing local water soaking type ultrasonic detection instrument and detection method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

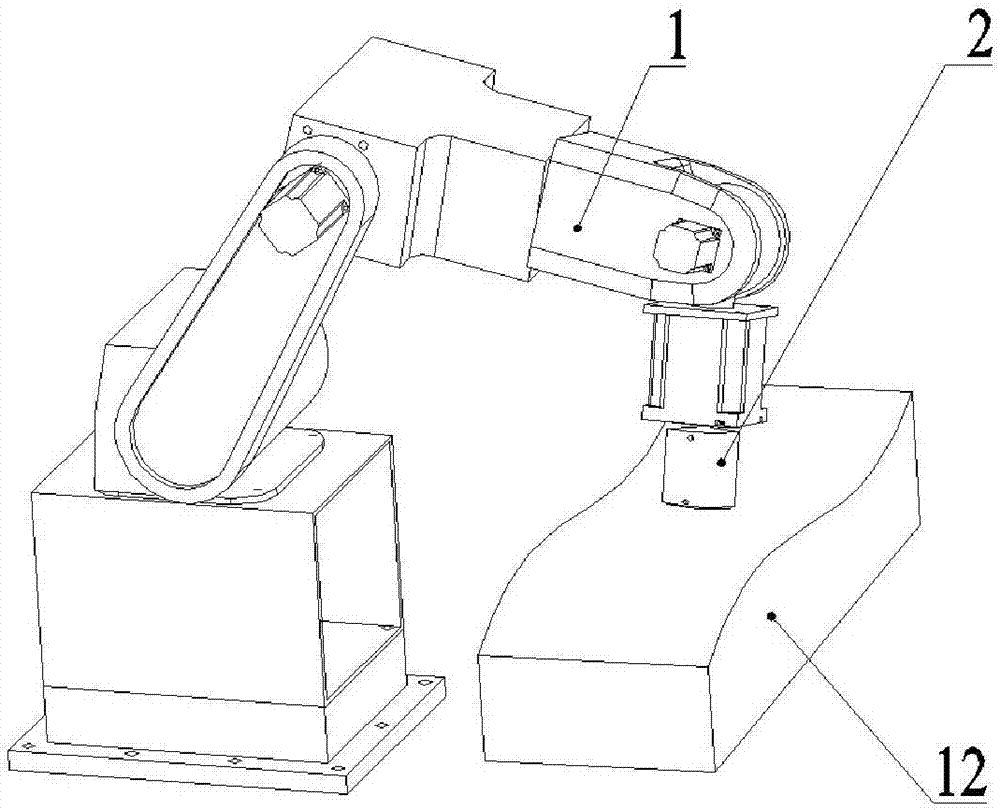

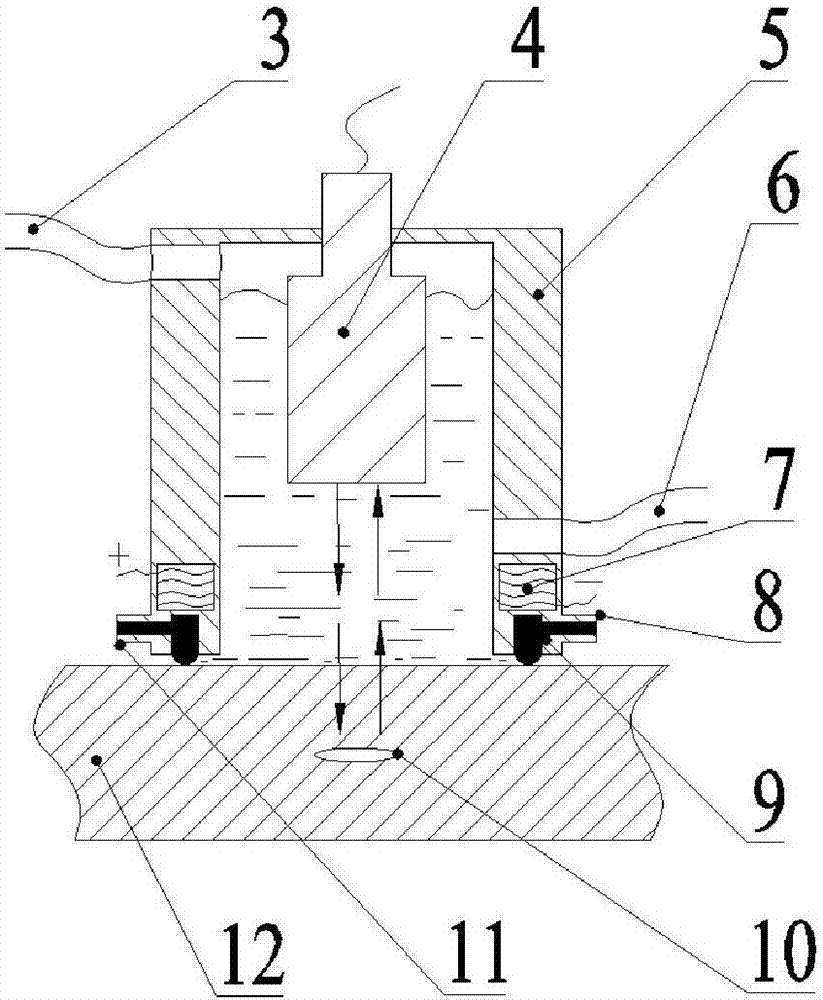

[0014] The present invention proposes a magnetic fluid sealed partial water immersion ultrasonic detector, which is mainly composed of a space curved surface scanning unit 1 and a local water immersion ultrasonic flaw detection unit 2, such as figure 1 shown. The spatial curved surface scanning unit 1 is mainly composed of a six-degree-of-freedom robot arm and its control system. Partial water immersion ultrasonic flaw detection unit 2 is mainly composed of ultrasonic probe 4, water storage cavity 5, magnetic fluid storage cavity 9, water inlet pipe 3, water outlet pipe 6, magnetic fluid inlet pipe 8, magnetic fluid outlet pipe 11, magnetic sensor Composed of a coil 7, a water pump and a magnetic fluid pump, the water pump transports or discharges water to the water storage cavity 5 through the water inlet pipe 3 or the water outlet pipe 6; Cavity 9 inputs ferrofluid or discharges ferrofluid, such as figure 2 Shown, the water pump and magnetic fluid pump are not shown in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com