Horizontal wall reserved hole manufacturing and plugging device and method

A plugging device and a technology for manufacturing devices, which are applied in the field preparation of building components, building construction, building maintenance, etc., can solve the problems of concrete or mortar hardening shrinkage, water seepage, water leakage, and impervious structures affecting structural impermeability, etc. problem, achieve the effect of improving water seepage and ensuring the effect of water stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

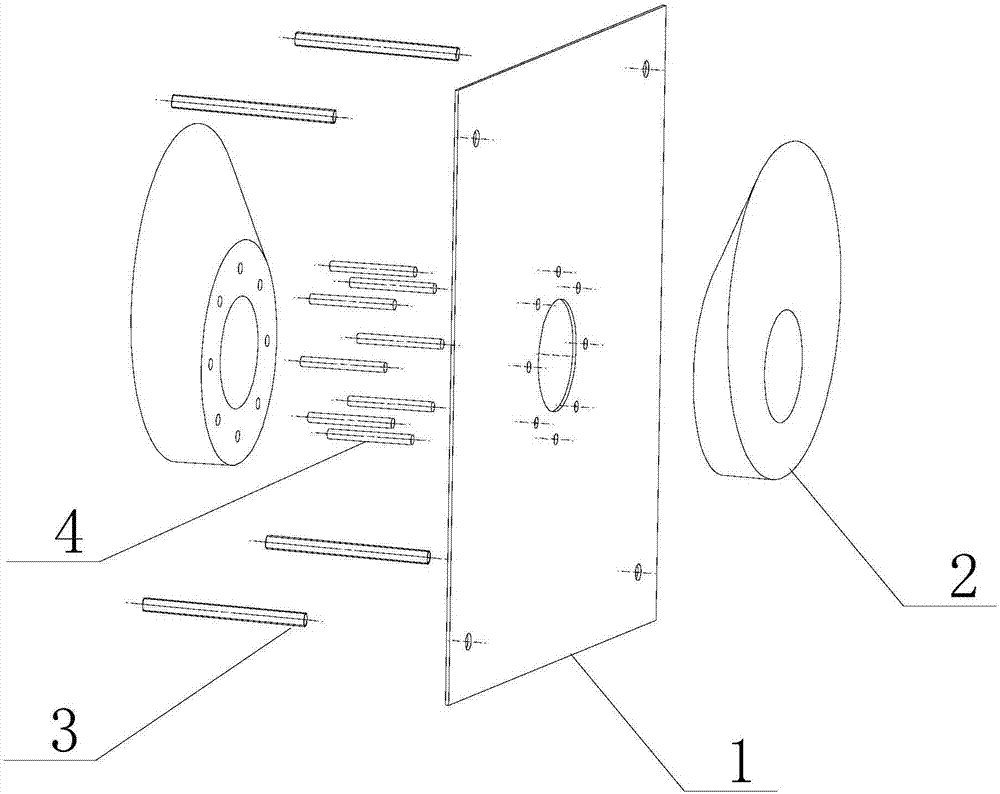

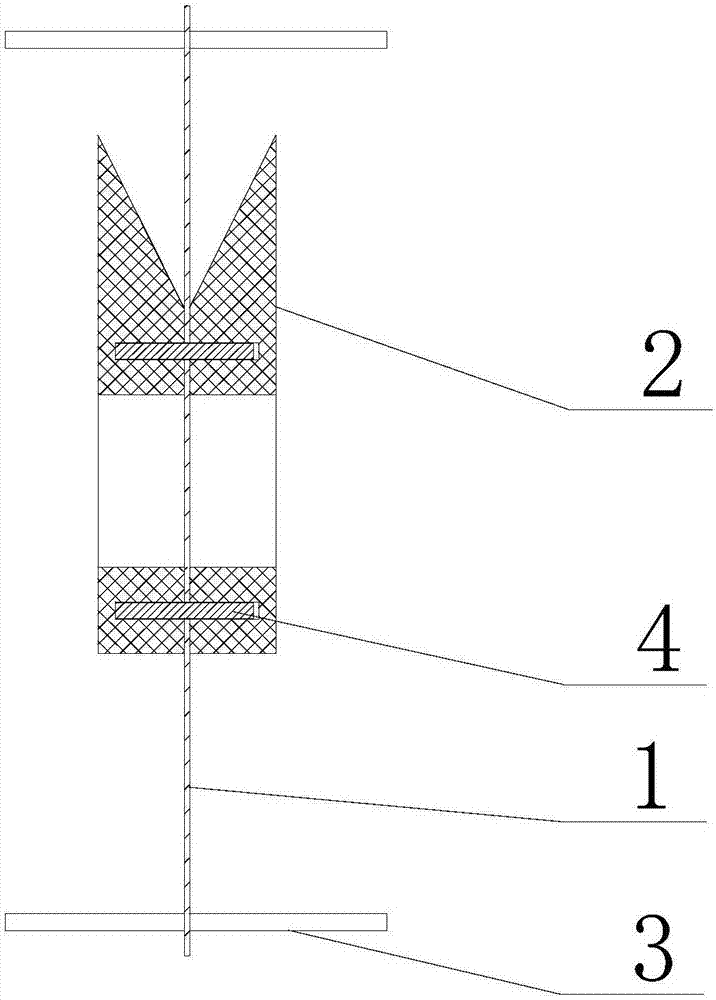

[0039] A manufacturing device for horizontally reserved holes in the wall, such as Figure 1~3 As shown, it includes: a water stop plate 1, two hole forming parts 2, multiple pins 4 and multiple screw rods 3, such as Figure 4 As shown, the water stop plate 1 is fixed in the middle of the wall, and a reserved hole 101 is opened in the center of the water stop plate 1, and a plurality of first pin holes 102 are opened on the water stop plate 1 and the outer periphery of the reserved hole 101. The outermost side of the plate 1 is also provided with a plurality of first screw holes 103, such as image 3 As shown, one pin 4 is arranged in each first pin hole 102, and the screw rod 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com