Composite Floor Slab with Lattice Two-way Beam and Its Construction Method

A technology of combining floor slabs and construction methods, applied in the directions of slabs, joists, girders, etc., to achieve the effects of improving on-site construction efficiency, light weight, construction safety and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

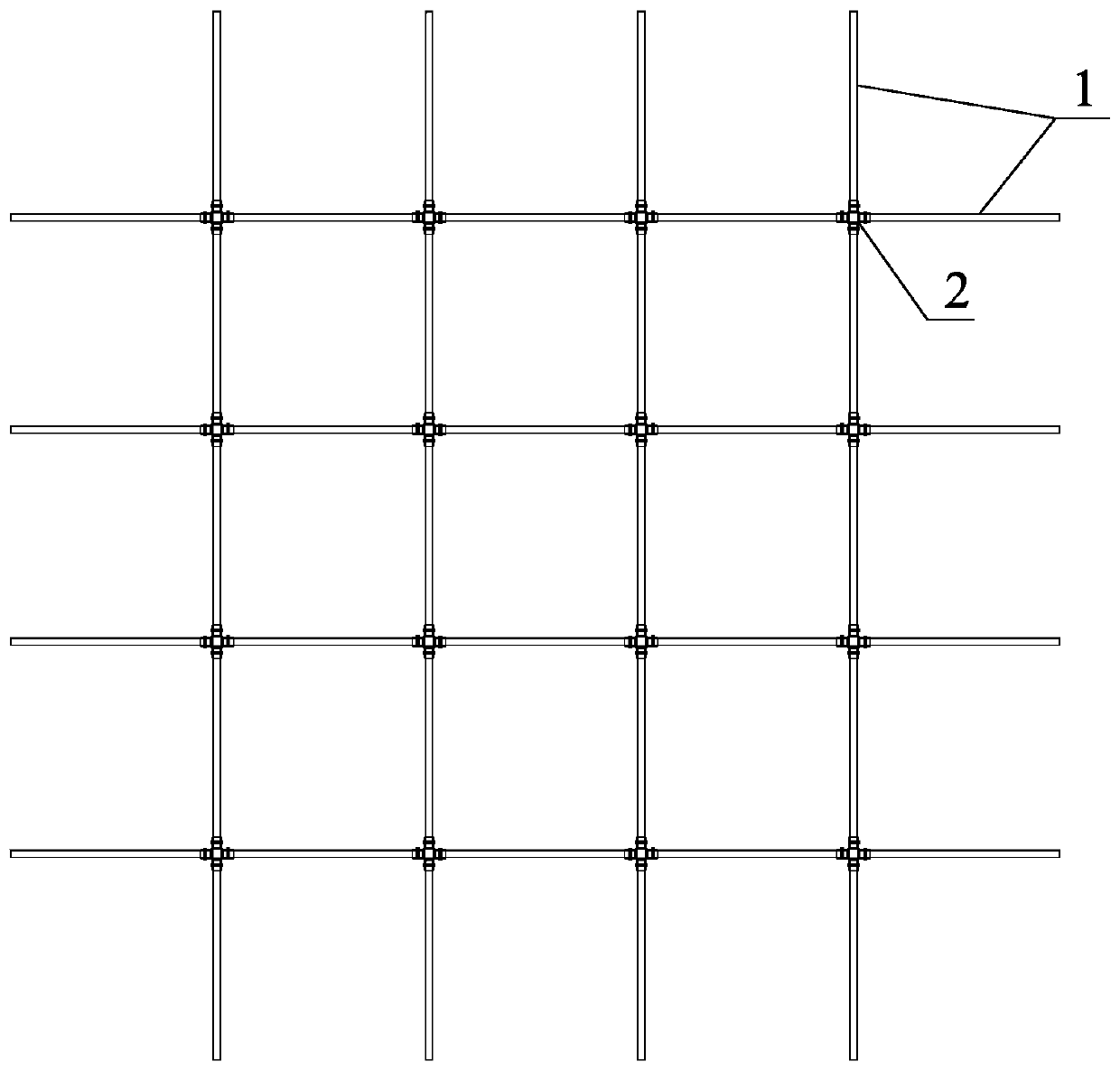

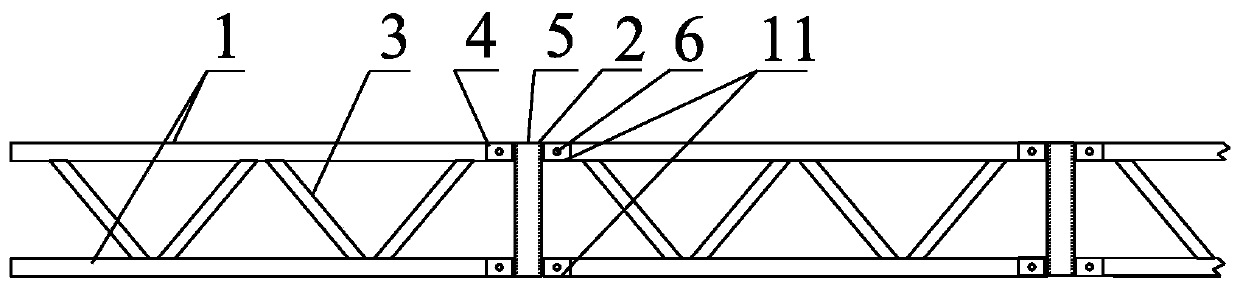

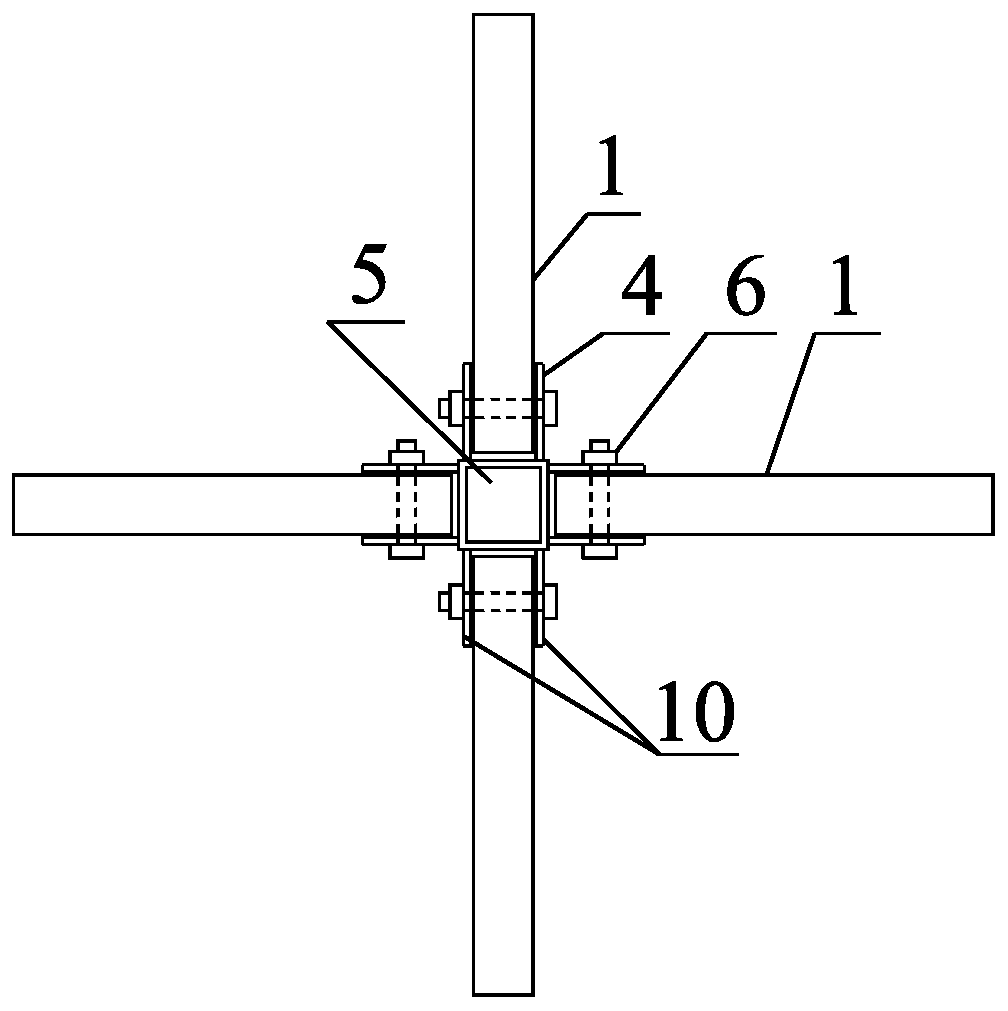

[0040] Such as figure 1 As shown, the trusses 9 are arranged in vertical and horizontal directions, and the trusses are segmented by two nodes, which can be made in a unified manner. The truss segments are connected to the node centerpieces of adjacent nodes. In this embodiment, the node centerpieces are vertical rectangles Tube 5, a typical rectangular tube is a square tube with the same length on each side of the cross-section, and the four outer sides of the square tube are connected with the truss section, such as figure 2 , the upper and lower chords of the four-section truss are fixedly connected to the upper and lower ends of the four sides of the square tube respectively.

[0041] A specific fixed connection method such as figure 2 , image 3 As shown, connecting slots 4 are symmetrically welded at the connection between the upper end and the lower end of the four sides of the rectangular tube 5, and the connecting slot 4 is provided with a pair of parallel side pl...

Embodiment 2

[0045] Such as Figure 4 As shown, the truss 9 is connected to the node central piece from the vertical and horizontal directions, and the node central piece is a vertically welded gusset plate 7 ( Figure 6 ), the horizontal section of the gusset plate 7 is a centrally symmetrical cross, and the chords 1 of the upper and lower floors of the four-section truss are fixedly connected to the upper and lower ends of the four protruding wing plates of the gusset plate 7 respectively.

[0046] The chord 1 is formed by a pair of symmetrically arranged angle steels fixedly connected back to each other, each side wing plate of a pair of angle steels is on a horizontal plane, and the other side wing plate fixedly clamps the connecting plate 8, as Figure 6 As shown, in the upper chord, the horizontally arranged flaps are at the upper part, and the interconnected flaps are vertically arranged at the lower part of the upper chord; on the contrary, the horizontally arranged flaps are at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com