A kind of steel plate girder bridge and its construction method

A construction method and a bottom-bearing technology, applied in bridges, bridge construction, bridge maintenance, etc., can solve problems such as potential safety hazards, train speed restriction, weak lateral connection, etc., achieve convenient disassembly and assembly, improve lateral stiffness, enhance The effect of horizontal linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

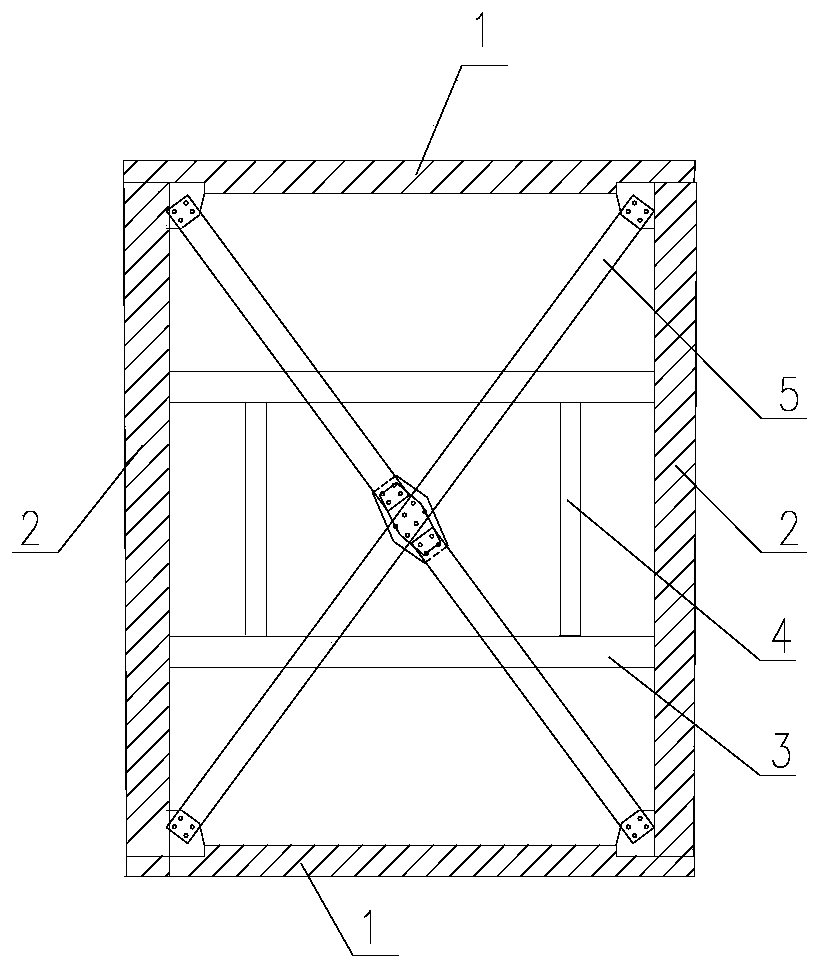

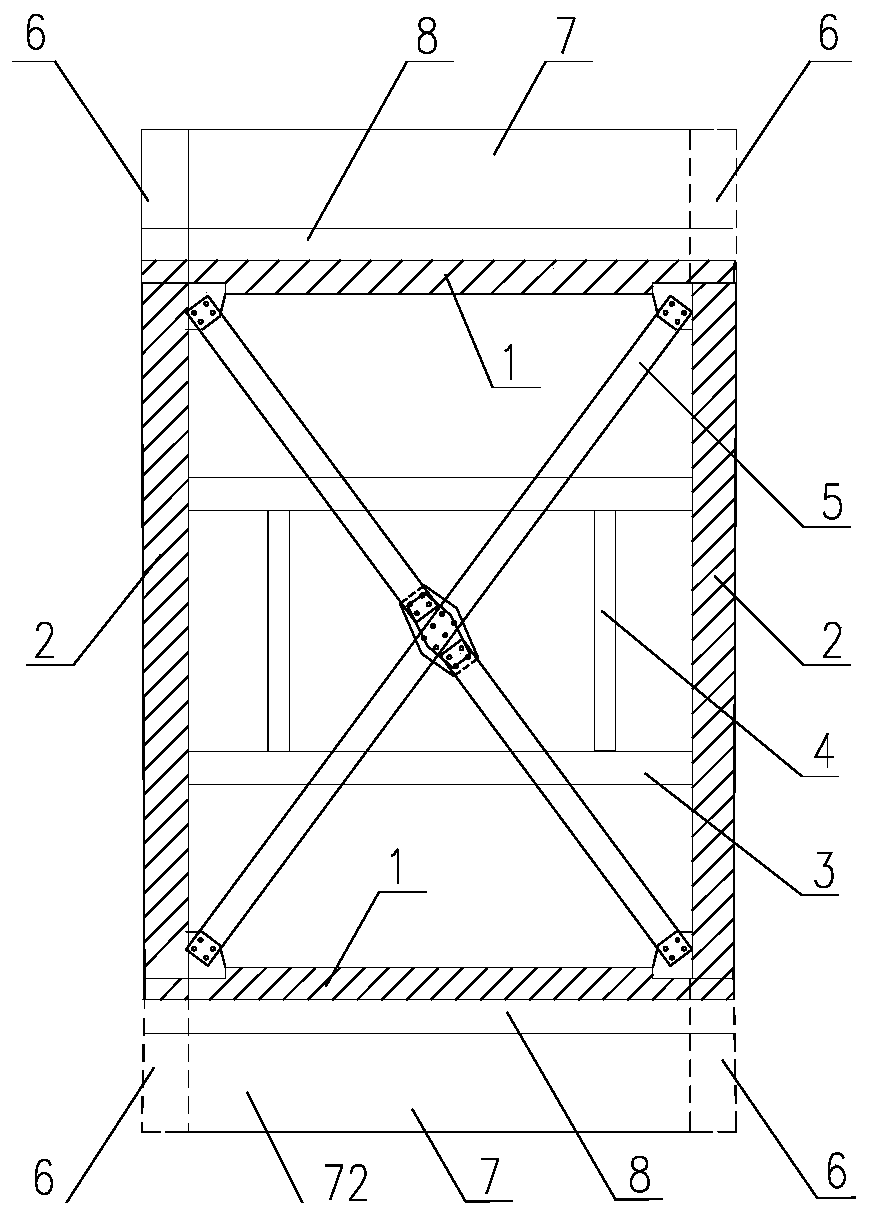

[0026] see Figure 2 to Figure 4 As shown, the embodiment of the present invention provides an under-supported steel plate girder bridge, which includes a bridge body, and the bridge body includes two main longitudinal girders 1 and a crossbeam 2 between the two main longitudinal girders 1, and the main longitudinal girder 1 Including the web 11, the top of the web 11 is provided with a horizontally extending upper flange plate 12, the bottom of the web 11 is provided with a horizontally extending lower flange plate 13, the bottom of the beam 2 is provided with a transverse connecting plate 6, and the transverse connecting plate 6 is two Each end is fixedly connected with a reinforcing component 7, and the bridge body is resisted between the two reinforcing components 7. The reinforcement assembly 7 is parallel to the main longitudinal beam 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com