Main cable layered anti-sliding structure for main saddles of suspension bridge

A main saddle, suspension bridge technology, applied in suspension bridges, bridges, bridge parts, etc., can solve the problems of weakening the stiffness of the middle tower, limited pressure, and increasing engineering costs, and achieves improved anti-skid performance, improved selection space, and improved anti-skid. horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

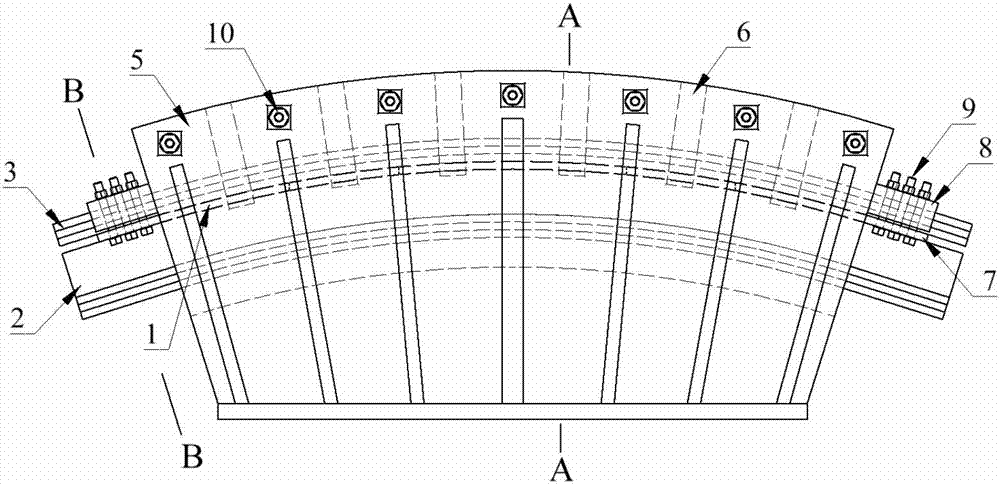

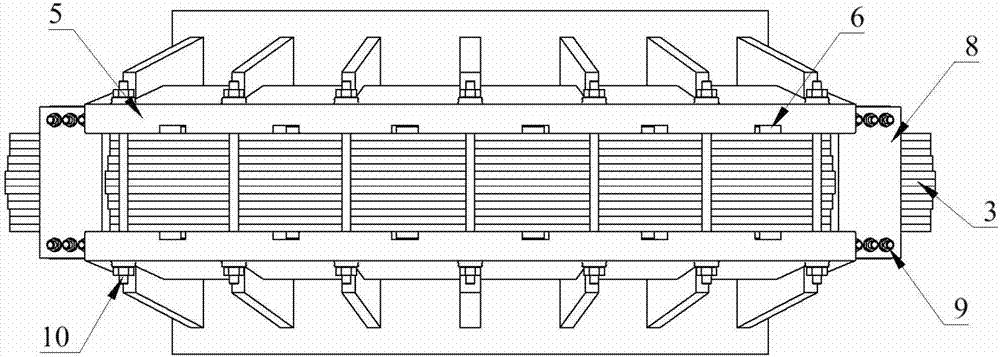

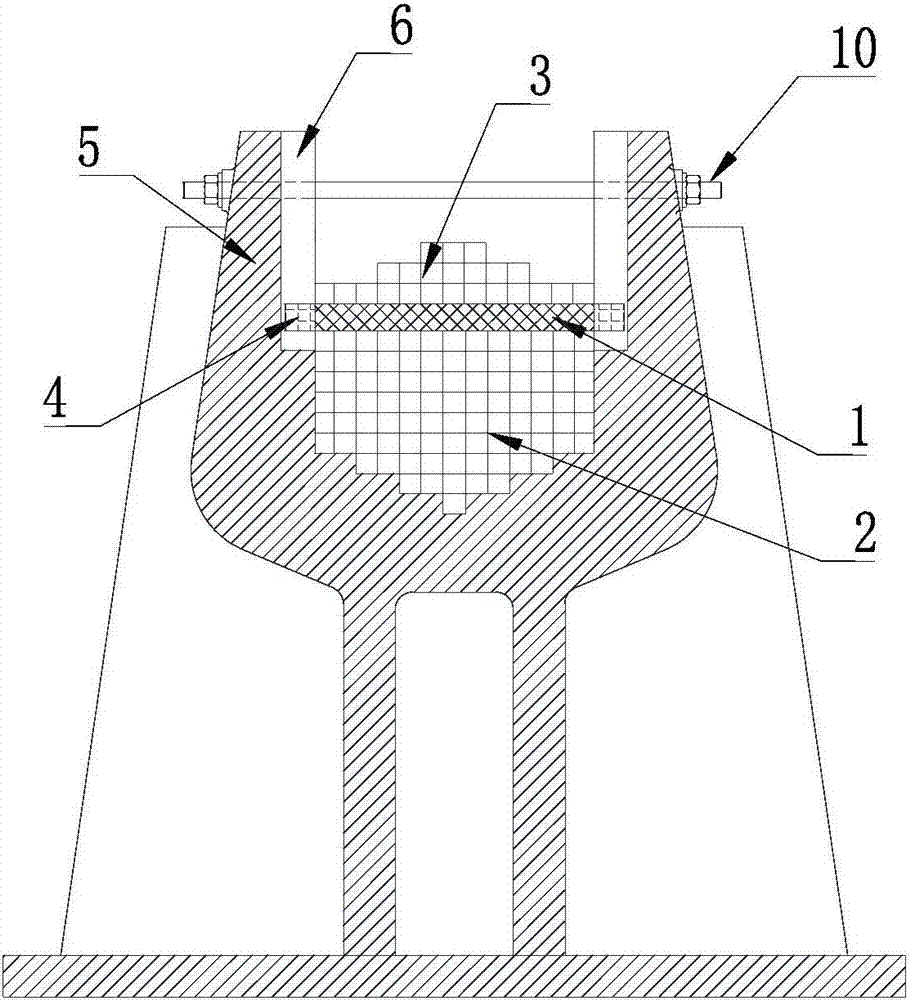

[0019] exist Figure 1 to Figure 5 In the shown embodiment of the layered anti-skid structure of the main cable, several friction splints 1 are provided along the longitudinal direction of the saddle groove of the main saddle, so that the main cable strands are divided into lower strands 2 and upper strands 3 . Both upper and lower surfaces of the friction splint 1 are designed as arc surfaces, so that the main cable strands can be in close contact with the friction splint 1 . Both sides of each friction splint 1 are provided with a tenon 4, which can move up and down along the slot 6 on the side wall 5 of the main saddle, so that the pressure of the upper strand 3 acting on the friction splint 1 can be transmitted to the lower layer Cable stock 2. Due to the longitudinal constraint of the groove 6 on the tenon 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com