Water-based auto parts anti-corrosion coating and preparation method thereof

A technology for auto parts and anti-corrosion coatings, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor corrosion resistance and outdoor weather resistance, slow drying speed of paint film, poor water resistance, etc. Achieve the effect of improving anti-ultraviolet radiation performance, improving anti-aging performance and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

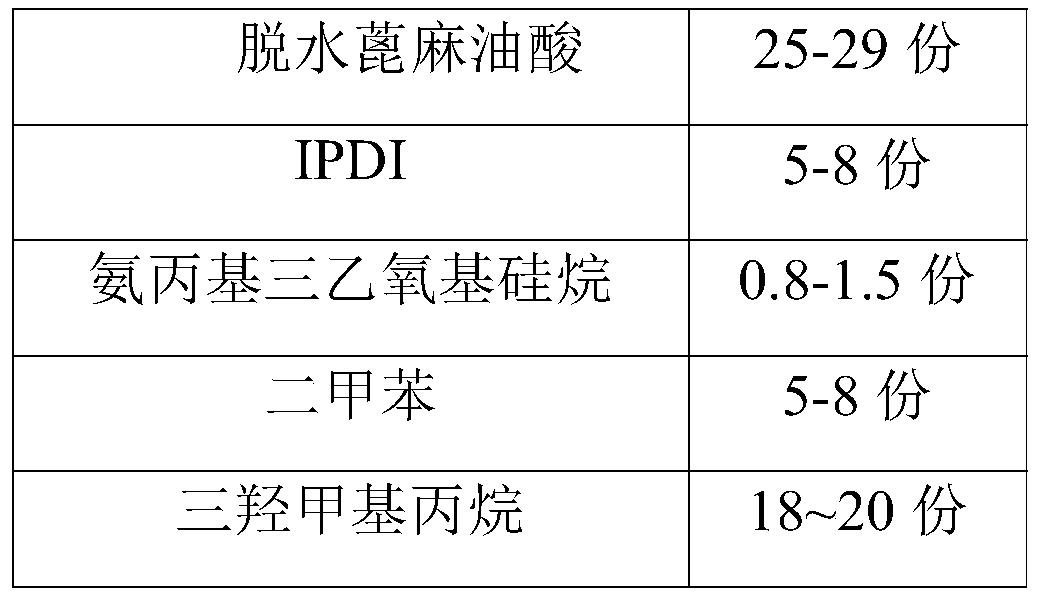

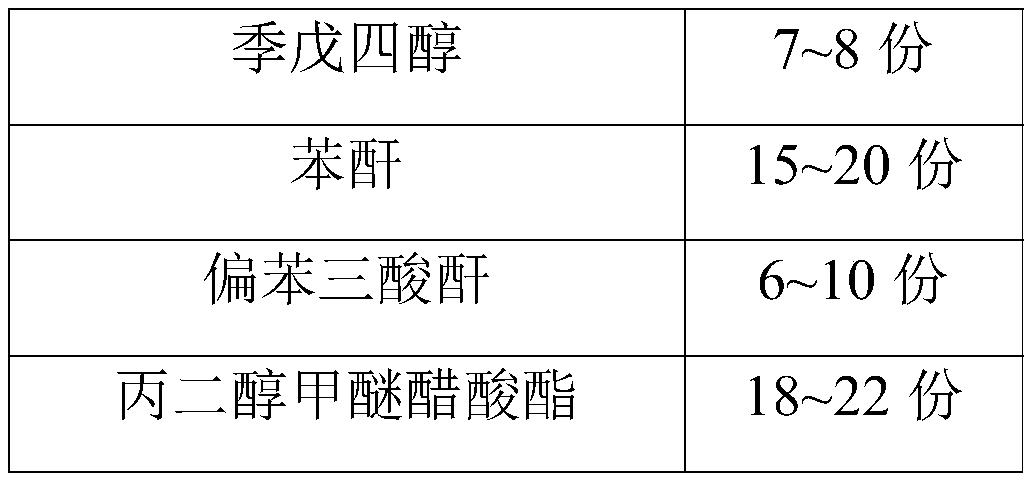

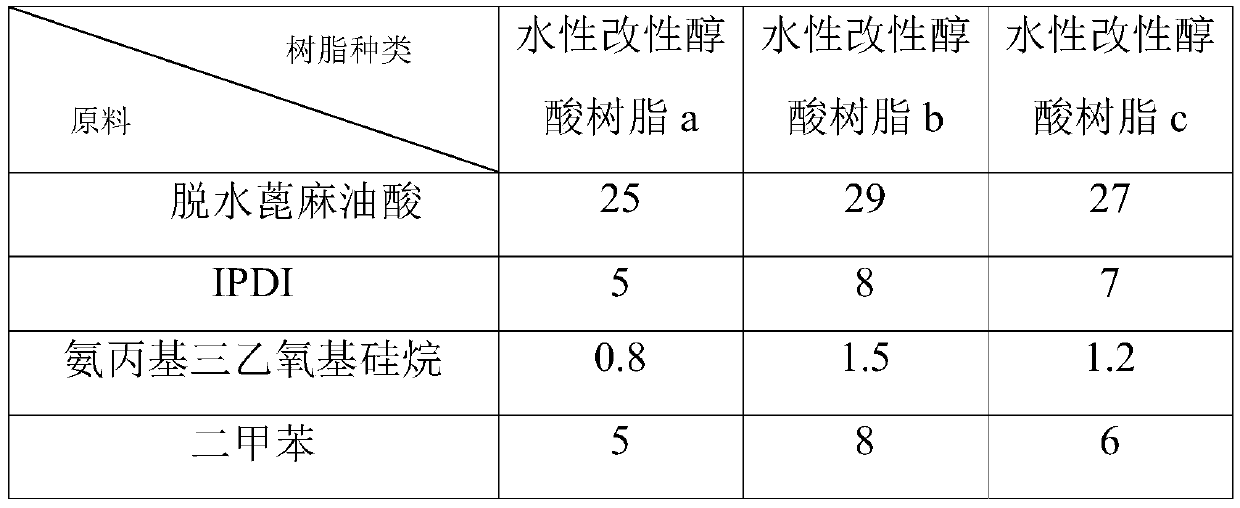

[0032] Preparation of water-based modified alkyd resin:

[0033] Water-based modified alkyd resin a, water-based modified alkyd resin b, and water-based modified alkyd resin c were prepared using the formula weight composition shown in the following table.

[0034]

[0035]

[0036] The preparation method of water-based modified alkyd resin is as follows:

[0037] Step a: Add dehydrated ricinoleic acid, phthalic anhydride, trimethylolpropane, pentaerythritol, and xylene into the reactor according to the formula amount, feed nitrogen, heat to 200-230°C for reaction, and measure the acid value every 30 minutes;

[0038] Step b: When the acid value drops to 8-12mgKOH / g, cool down to 80-100°C, add IPDI and aminopropyltriethoxysilane, and react for 2h;

[0039] Step c: After heating up to 200-230°C, add trimellitic anhydride, measure the acid value every 30 minutes, and when the acid value drops to 15-30mgKOH / g, cool down to below 100°C and add propylene glycol methyl ether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com