Preparation method of a temperature-sensitive chelating gel concrete internal curing agent

An internal and curing agent technology for concrete, applied in the field of building material admixtures, can solve problems such as poor release performance, reduced concrete work performance, and can not meet construction requirements, etc. The effect of early cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

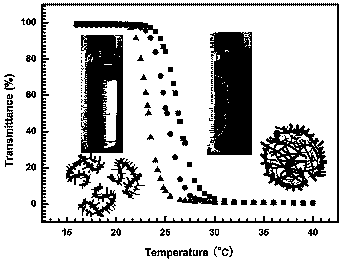

Method used

Image

Examples

Embodiment 1

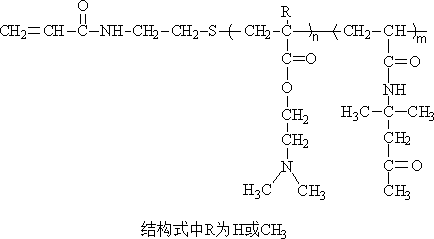

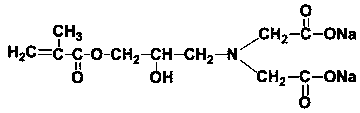

[0025] A preparation method of temperature-sensitive chelating gel concrete internal curing agent, comprising the following steps:

[0026] (1) Dissolve 36g of acrylic acid in 180g of distilled water, stir and mix evenly, add 20g of sodium hydroxide three times under the condition of ice water cooling to adjust the pH to neutral, add 12g of chelating functional monomer, 11g of propylene in sequence under stirring Stir the amide to dissolve completely, and then slowly add 12g of temperature-sensitive macromonomer several times under the action of strong stirring. For N,N-methylenebisacrylamide, continue to pass nitrogen gas for 30-60 minutes, seal, and keep the temperature at 20-50°C for 8-24h.

[0027] (2) Cut the product obtained above into pieces, then put it into an oven, and heat it at 85~90 o C Dry at constant temperature for 6~8h, crush the dried product with a pulverizer, and then sieve it with a sieve until the granular temperature-sensitive chelating gel concrete int...

Embodiment 2

[0030] A preparation method of temperature-sensitive chelating gel concrete internal curing agent, comprising the following steps:

[0031] (1) Dissolve 48g of sodium methacrylsulfonate in 180g of distilled water and stir to dissolve, then add 12g of chelating functional monomer and 19g of N-methacrylamide to dissolve completely under stirring, and then divide under strong stirring Slowly add 12g of temperature-sensitive macromonomer several times to dissolve completely, and then add 3g of potassium persulfate and 3g of sodium sulfite composite initiator, 3g of N,N-methylenebisacrylamide in sequence after passing nitrogen gas for 30 minutes, and continue Blow nitrogen for 30-60 minutes, seal, and keep the temperature at 20-50°C for 8-24h.

[0032] (2) Cut the product obtained above into pieces, then put it into an oven, and heat it at 85~90 o C Dry at constant temperature for 6~8h, crush the dried product with a pulverizer, and then sieve it with a sieve until the granular te...

Embodiment 3

[0034] Embodiment 3 A preparation method of temperature-sensitive chelating gel concrete internal curing agent, comprising the following steps:

[0035] (1) Dissolve 36g of 2-acrylamido-2-methylpropanesulfonic acid in 180g of distilled water, stir and mix evenly, add 7g of sodium hydroxide under ice water cooling condition to adjust the pH to neutral, then add Stir 12g of chelating functional monomer and 21g of acrylamide to completely dissolve, and then slowly add 12g of temperature-sensitive macromonomer several times under the action of strong stirring. Ammonium and 3g ascorbic acid composite initiator, 6g ethylene glycol bisacryloyl ester, continue to pass nitrogen gas for 30-60 minutes, seal, and keep the temperature at 20-50°C for 8-24h.

[0036] (2) Cut the product obtained above into pieces, then put it into an oven, and heat it at 85~90 o C Dry at constant temperature for 6~8h, crush the dried product with a pulverizer, and then sieve it with a sieve until the granul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com