Lifting appliance capable of adjusting steel rail posture in lifting process

A spreader and attitude technology, which is applied in the field of spreaders to adjust the attitude of rails, can solve the problems of time-consuming, labor-intensive, personal injury, etc., and achieve the effects of expanding application scenarios, improving production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

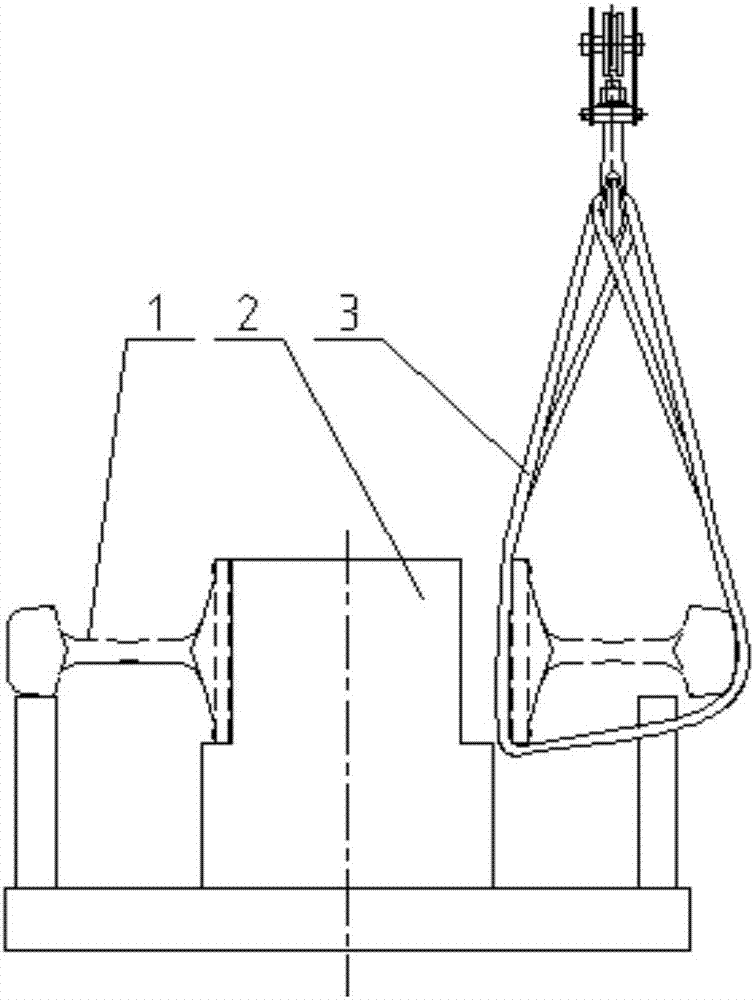

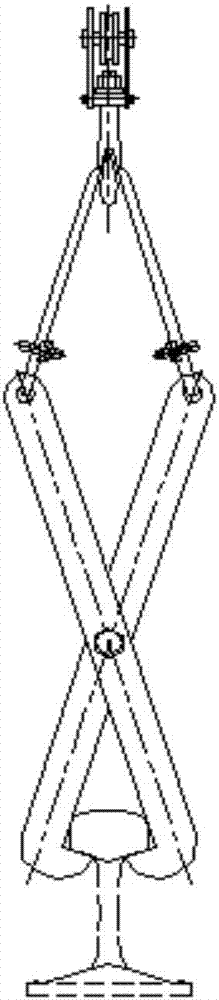

[0029] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] The hanger capable of adjusting rail posture during hoisting according to the present invention includes a clamp and a steel wire rope for hoisting; the clamp is composed of inner tong handles 6 and outer tong handles 5 which are cross-nested and installed;

[0031] The inner pliers handle 6 is bent in Z-shape as a whole to form a lifting handle and a jaw handle;

[0032] The outer tong handle 5 is composed of two scoop-shaped bent parts of the same shape, and the two bent parts are superimposed side by side and fixedly installed at a distance to form a lifting handle and a jaw handle; the end of the jaw handle faces upwards as the outer The head of the pliers handle 5 is welded to a connecting plate 10 at the end of the pliers handle, which is used to fix the head and limit the distance between the two bent parts. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com