Manned spacecraft extravehicular maintenance ground simulating system

A manned spacecraft and ground simulation technology, applied in the field of manned spacecraft test, can solve the problem of being unable to simulate any relative position between test personnel and maintenance equipment, and achieve the effect of improving continuity, effectiveness and test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

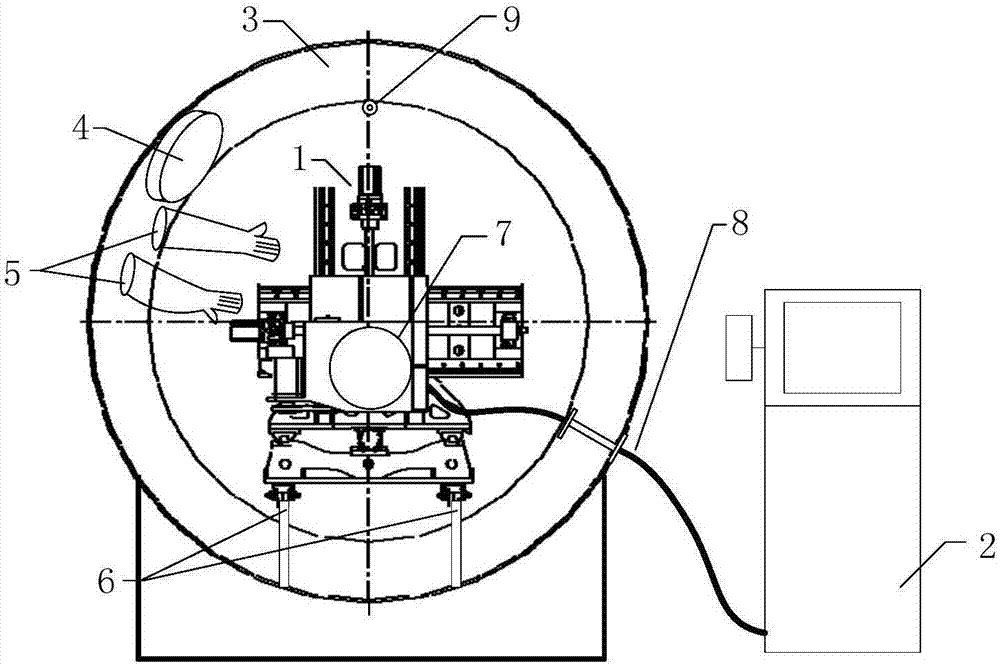

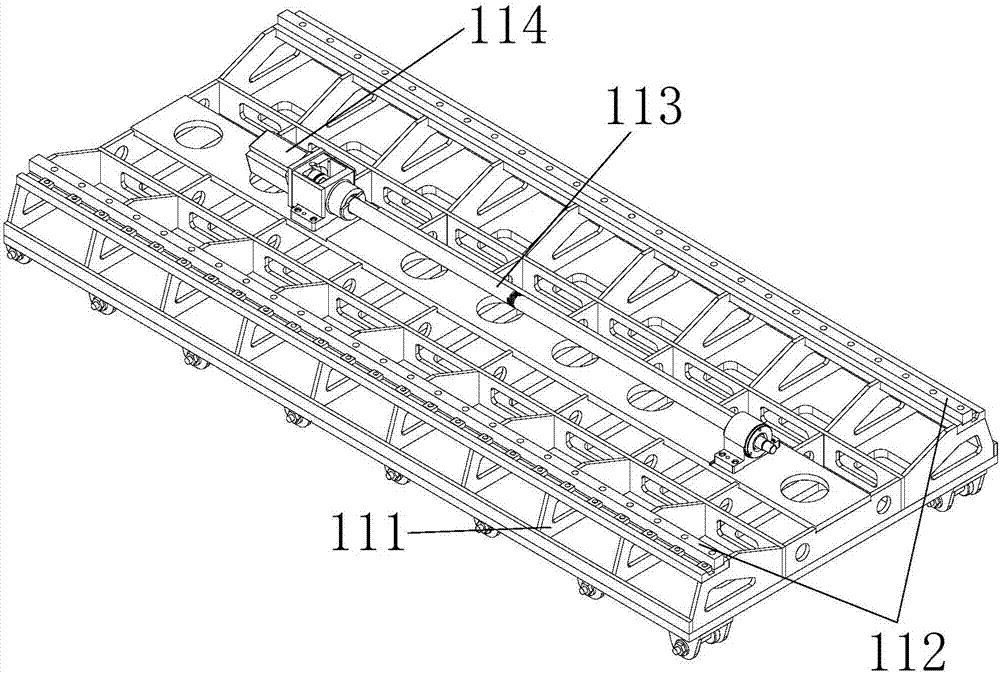

[0054] Such as figure 1 As shown, the vacuum tank 3 adopts a cylindrical horizontal structure, the main material is 0Cr18Ni9Ti, the inner diameter is 2000mm, and the length of the straight section is 2000mm; the vacuum tank 3 is designed with two doors, and there are operation methods for the test personnel on the door. Lan, the size of the big flange is 1000mm in diameter, and two space suit gloves 5 and one observation window 4 are installed on the big flange. The vertical distance between the center of the hole is 280mm, and the tester can see the entire operation interface through the observation window 4. Two guide rails are installed in the vacuum tank 3 with a distance of 700mm, and the load bearing capacity of the guide rails is 1.2T.

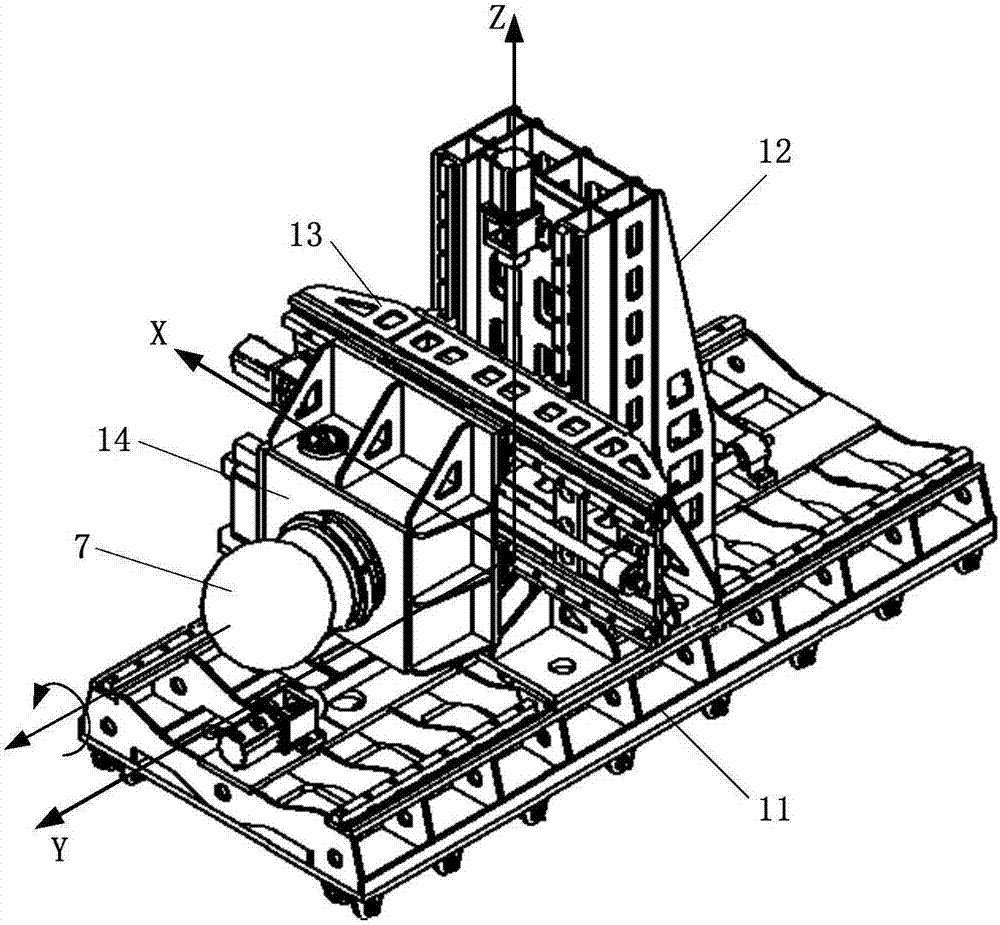

[0055] Servo mechanism 1, the vertical stroke is 300mm, the axial stroke of the vacuum tank is 1200mm, the axial stroke perpendicular to the vacuum tank is 800mm in the horizontal plane, the moving speed is 0.3~1.5m / min, the angular str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com