Metal shell as well as surface treatment method and electronic equipment thereof

A technology for surface treatment and electronic equipment, applied in the field of metal shells and electronic equipment, it can solve the problems of lack of translucency and high-end feeling, rough and uneven drawing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

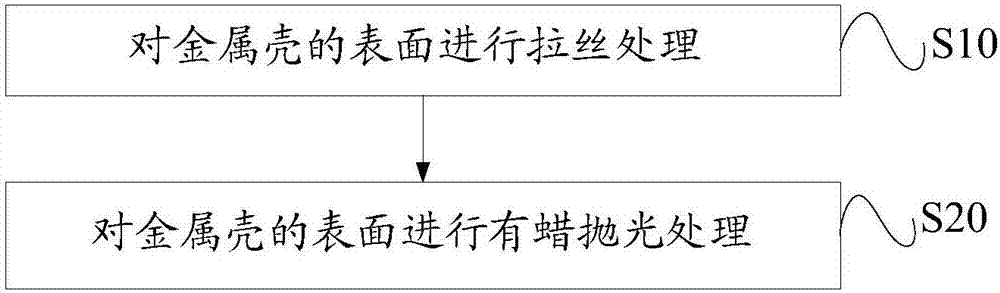

[0038] Such as figure 1 As shown, a method for surface treatment of a metal shell provided according to some embodiments of the present invention includes:

[0039] Step S20, performing wire drawing treatment on the surface of the metal shell;

[0040] In step S40, wax polishing is performed on the surface of the wire-drawn metal shell.

[0041] After brushing the surface of the metal shell, wax polishing (wax polishing) is performed on the brushed surface of the metal shell. The wax polishing process can significantly improve the transparency of the metal shell surface, thereby improving the high-end sense of the metal shell , to avoid the simple silky feeling on the surface of the metal shell, and add a bright and transparent effect to the wire drawing of the metal shell. Preferably, the surface of the metal shell is polished with a load on the surface of the metal shell by using a flat grinder, a carpet consumable, and a polishing liquid (fine polishing liquid) during the...

Embodiment 2

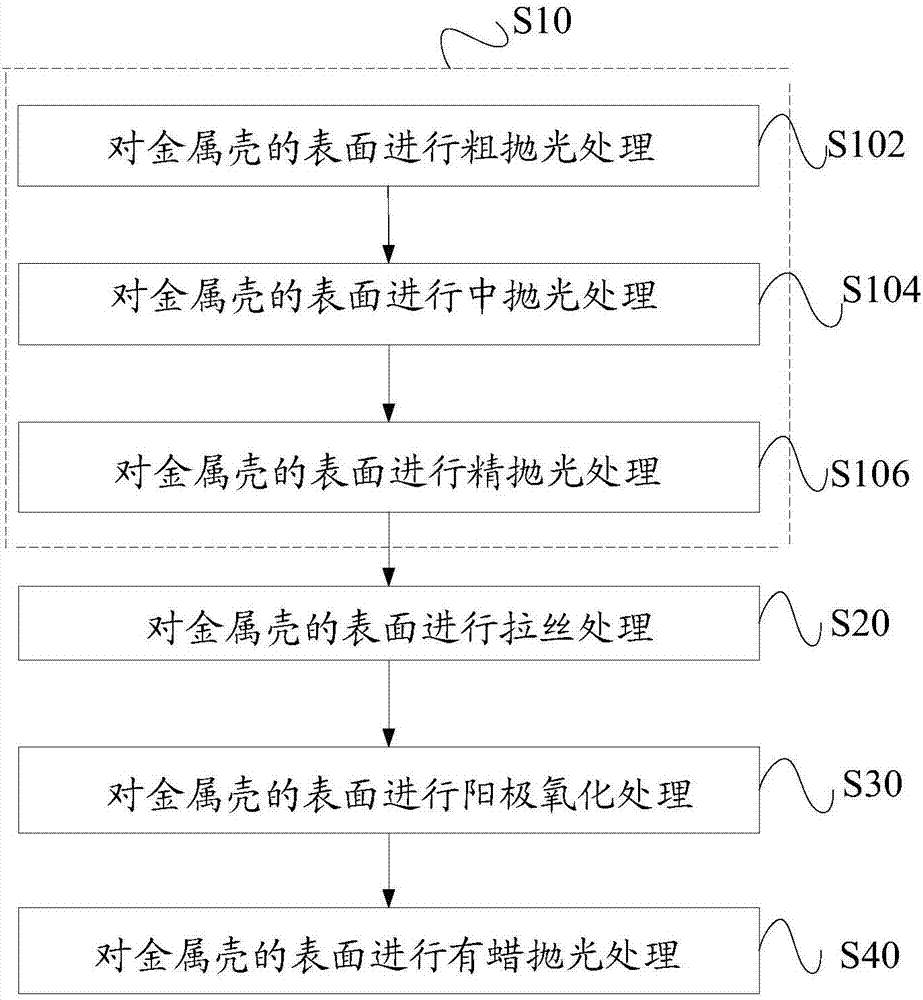

[0043] Such as figure 2 Shown, a kind of surface treatment method of metal shell comprises:

[0044] Step S10, polishing the surface of the metal shell.

[0045] Preferably, step S10 specifically includes:

[0046] Step S102, rough polishing the surface of the metal shell;

[0047] Step S104, performing medium polishing treatment on the surface of the metal shell after the rough polishing treatment;

[0048] Step S106, performing fine polishing treatment on the surface of the metal shell after the middle polishing treatment.

[0049] Here, the rough polishing treatment in step S102 can also be understood as performing a grinding treatment on the surface of the metal shell. Step S102 is specifically: using a flat grinder plus 600# nylon sand for grinding. Step S104 specifically includes: using a flat grinder to add cloth wheel consumables (polishing cloth wheel) and polishing fluid (intermediate polishing fluid) to polish under load. Step S104 specifically includes: polish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com