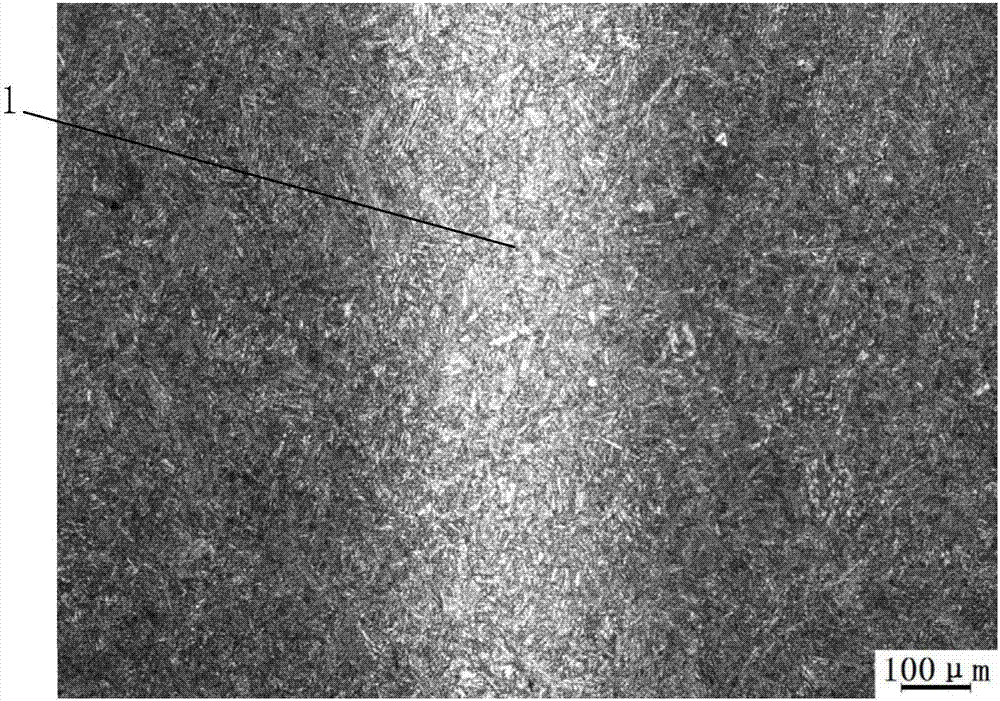

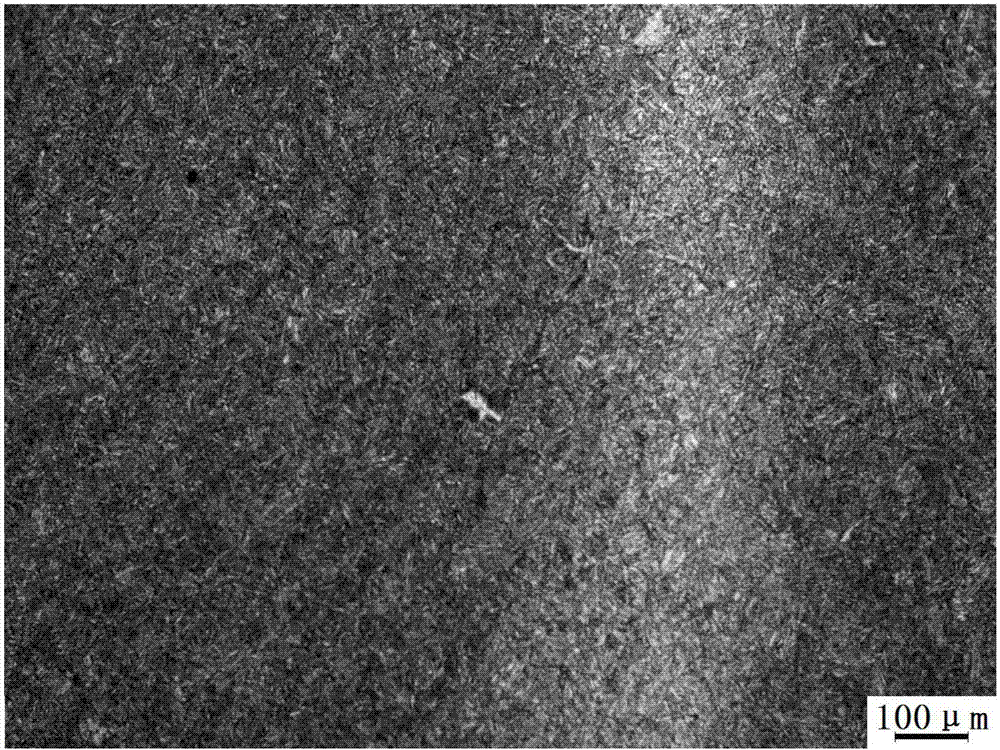

Technological method for controlling 'white block' tissues in bainite steel rail flash welding joint

A process method, bainite technology, applied in the field of rail welding, can solve the problems of large size and large number of "white blocks", achieve the effects of stable welding quality, improved service performance, and improved appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Through the method of the present invention, during the welding process of the bainite rail by the rail flash butt welding equipment, the following control is performed on the flash flat stage, the pulsation stage, the accelerated burning stage, the upsetting stage and the pressure holding stage in sequence:

[0050] Control the welding heat input in the flashing stage to 2.2MJ, and the duration is 22s;

[0051] The welding heat input in the control pulsation stage is 4.9MJ, the rail consumption is 2.5mm, and the duration is 53.9s;

[0052] Control the welding heat input in the accelerated burning stage to 0.6MJ, the rail consumption to 8.2mm, and the duration to 20.5s;

[0053] Control the welding heat input in the upsetting stage to 0.1MJ, the upsetting amount to 14.1mm, the live upsetting time to 0.3s, and the duration to 8.1s;

[0054] The holding pressure of the control holding stage is 27.5T, and the duration is 12.7s;

[0055] The total welding heat input is co...

Embodiment 2

[0057] Through the method of the present invention, during the welding process of the bainite rail by the rail flash butt welding equipment, the following control is performed on the flash flat stage, the pulsation stage, the accelerated burning stage, the upsetting stage and the pressure holding stage in sequence:

[0058] Control the welding heat input in the flashing stage to 2.3MJ, and the duration is 23s;

[0059] The welding heat input in the control pulsation stage is 5.1MJ, the rail consumption is 3.0mm, and the duration is 57.9s;

[0060] Control the welding heat input in the accelerated burning stage to 0.7MJ, the rail consumption to 8.5mm, and the duration to 20.5s;

[0061] Control the welding heat input in the upsetting stage to 0.1MJ, the upsetting amount to 15.3mm, the live upsetting time to 0.5s, and the duration to 7.8s;

[0062] Control the holding pressure in the holding stage to 26.7T, and the duration is 11s;

[0063] The total welding heat input is cont...

Embodiment 3

[0065] Through the method of the present invention, during the welding process of the bainite rail by the rail flash butt welding equipment, the following control is performed on the flash flat stage, the pulsation stage, the accelerated burning stage, the upsetting stage and the pressure holding stage in sequence:

[0066] Control the welding heat input in the flashing stage to 2.3MJ, and the duration is 22.5s;

[0067] The welding heat input in the control pulsation stage is 5.1MJ, the rail consumption is 2.8mm, and the duration is 52s;

[0068] Control the welding heat input in the accelerated burning stage to 0.5MJ, the rail consumption to 7.9mm, and the duration to 23.5s;

[0069] Control the welding heat input in the upsetting stage to 0.1MJ, the upsetting amount to 14.9mm, the live upsetting time to 0.4s, and the duration to 8.1s;

[0070] The holding pressure of the control holding stage is 27.5T, and the duration is 12.9s;

[0071] The total welding heat input is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com