Ore crushing equipment capable of facilitating sorting

A kind of ore crushing and sorting technology, which is applied in the direction of grain processing, etc., can solve the problems of loose parts inside the equipment, affecting the service life of the equipment, and affecting the lives of residents, so as to achieve the effects of prolonging the service life, speeding up the screening speed and reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

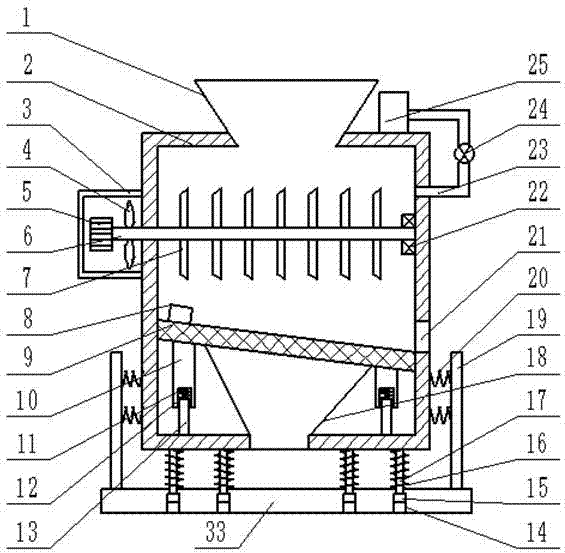

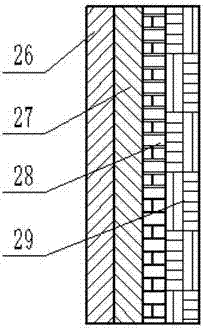

[0018] see Figure 1-3 , a convenient ore crushing equipment for sorting, including a crushing box 2, a dust removal box 25 and a bottom plate 33, and the side walls of the crushing box 2 are sequentially provided with a sound-absorbing layer 26, a heat-resistant layer 27, and a waterproof layer 28 from outside to inside And the wear-resistant layer 29, the middle part of the upper end of the crushing box 2 is connected with the feed hopper 1, the upper right side of the crushing box 2 is provided with a dust removal box 25, the dust removal box 25 communicates with the inside of the crushing box 2 through the dust removal pipe 23, and the dust removal pipe 23 is fixed A blower fan 24 is connected, and a primary filter 30, an activated carbon filter 31 and a secondary filter 32 are successively arranged in the dust removal box 25 from left to right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com