Acid-base bifunctional metal organic skeletal catalyst and preparation method and application thereof

A metal-organic framework and acid-base bifunctional technology, which is applied in the field of acid-base bifunctional metal-organic framework catalysts and their preparation, can solve problems such as poor catalytic performance, restrictions on the large-scale synthesis and use of acid-base bifunctional catalysts, and complicated preparation processes. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. UiO-66-NH 2 -SO 3 The preparation method of H is characterized in that it is carried out according to the following steps:

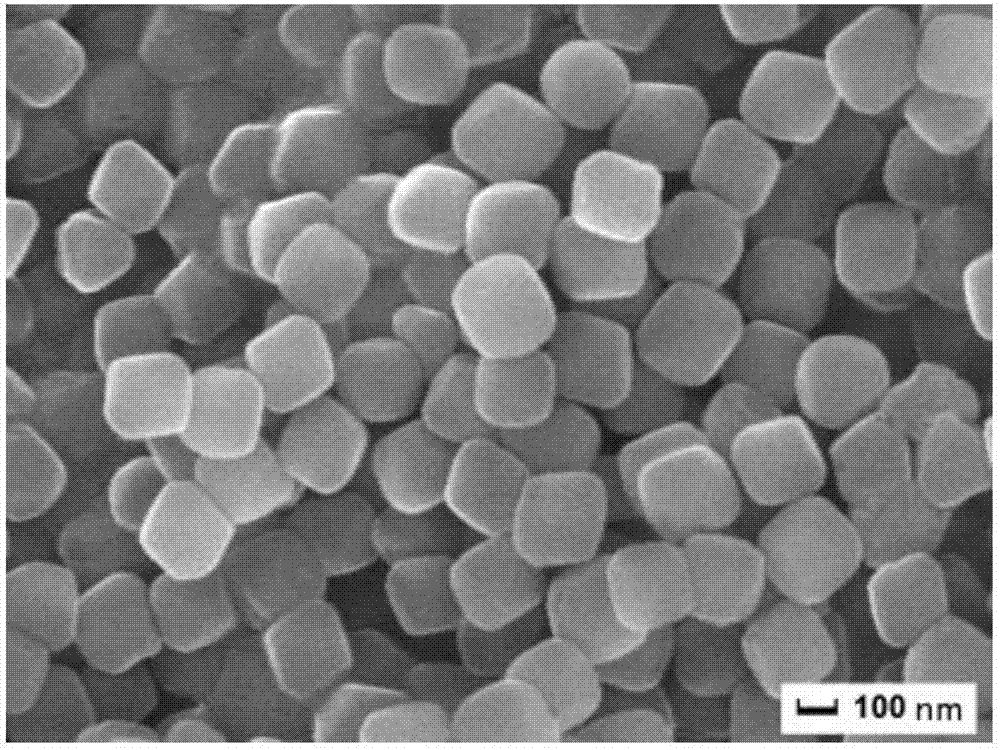

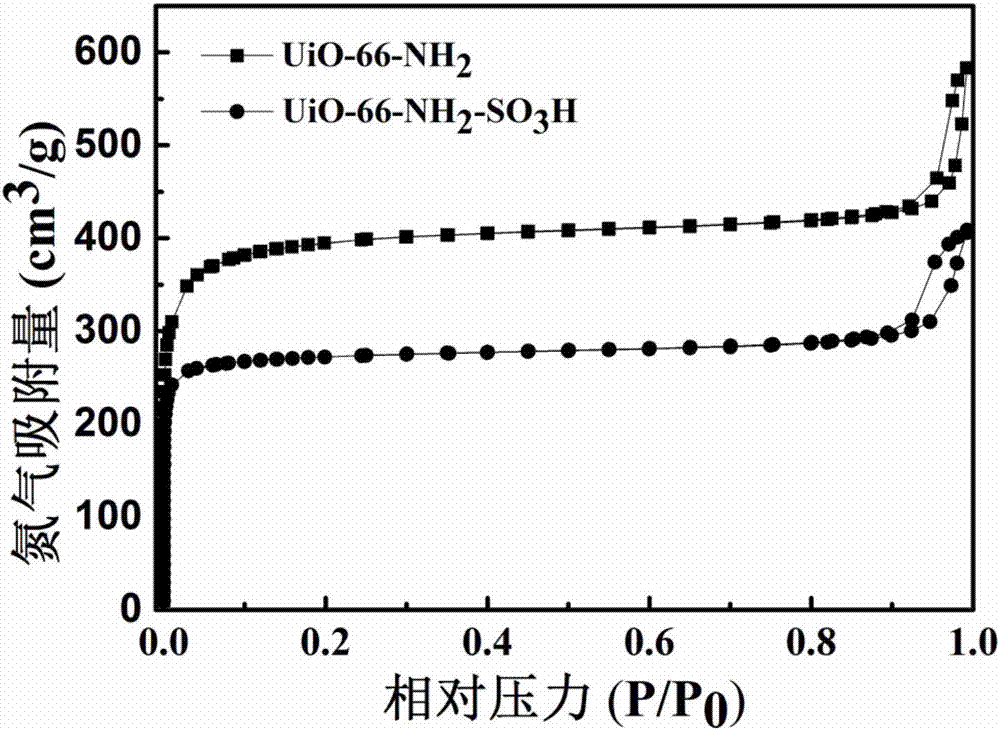

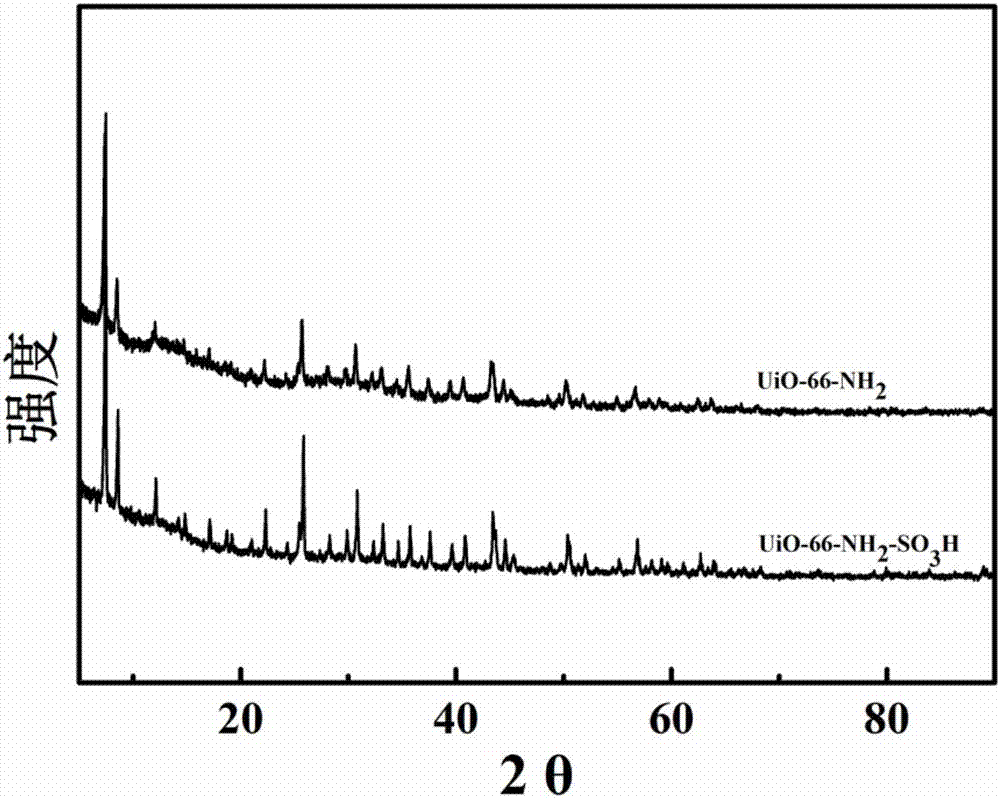

[0026] (1) Dissolve 1.8g of zirconium chloride and 1.2g of 2-aminoterephthalic acid in 150mL of weakly acidic 4 / 1 water and acid mixed solvent, disperse the mixed system evenly under ultrasonic conditions, and then put it in a 250mL In the flask, react in a water bath at 90°C for 24h. The reacted product was collected by filtration and washed 3 times with deionized water. The washed product was soaked in methanol for two days, filtered, and then dried under vacuum at 100 °C to obtain UiO-66-NH 2 Material.

[0027] (2) Prepare a mixed solution containing 575 μL of 1,3-propane sultone and 250 mL of chloroform in a flask, and prepare 0.67 g of UiO-66-NH 2 The crystals were placed in a flask, heated in a water bath at 45° C. for 3 h, and then the obtained solid product was centrifuged and washed by Soxhlet extraction (first with acetonitrile f...

Embodiment 2

[0045] 1. UiO-66-NH 2 -SO 3 The preparation method of H is characterized in that it is carried out according to the following steps:

[0046] (1) Dissolve 0.06g of zirconium chloride and 0.04g of 2-aminoterephthalic acid in 5mL of weakly acidic 3 / 2 water and acid mixed solvent, disperse the mixed system evenly under ultrasonic conditions, and then put it in 25mL In a flask, react in a water bath at 80°C for 12h. The reacted product was collected by filtration and washed 3 times with deionized water. The washed product was soaked in methanol for two days, filtered, and then dried under vacuum at 100 °C to obtain UiO-66-NH 2 Material.

[0047] (2) Prepare a mixed solution containing 11.5 μL of 1,3-propane sultone and 5 mL of chloroform in a flask, and prepare 0.01 g of UiO-66-NH 2 The crystals were placed in a flask, heated in a water bath at 30° C. for 1 h, and then the obtained solid product was centrifuged and washed by Soxhlet extraction (first with acetonitrile for 12 ...

Embodiment 3

[0055] 1. UiO-66-NH 2 -SO 3 The preparation method of H is characterized in that it is carried out according to the following steps:

[0056] (1) 3.6g of zirconium chloride and 2.6g of 2-aminoterephthalic acid were dissolved in 300mL of weakly acidic 6.5 / 1 water and acid mixed solvent, and the mixed system was dispersed evenly under ultrasonic conditions, and then placed in a 500mL In the flask, react in a bath at 100°C for 36h. The reacted product was collected by filtration and washed 3 times with deionized water. The washed product was soaked in methanol for two days, filtered, and then dried under vacuum at 100 °C to obtain UiO-66-NH 2 Material.

[0057] (2) Prepare a mixed solution containing 1150 μL of 1,3-propane sultone and 500 mL of chloroform in a flask, and prepare 1.33 g of UiO-66-NH 2 The crystals were placed in a flask, heated in a water bath at 50°C for 12 hours, and then the obtained solid product was centrifuged and washed by Soxhlet extraction (first was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com