Environment-friendly straw feed manufacturing equipment

A technology for straw feed and manufacturing equipment, which is applied in the fields of feed, food science, application, etc., can solve the problems of increasing the cost of feed and affecting the cost of breeding, and achieves the effect of simple structure, reduced cost and improved storage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

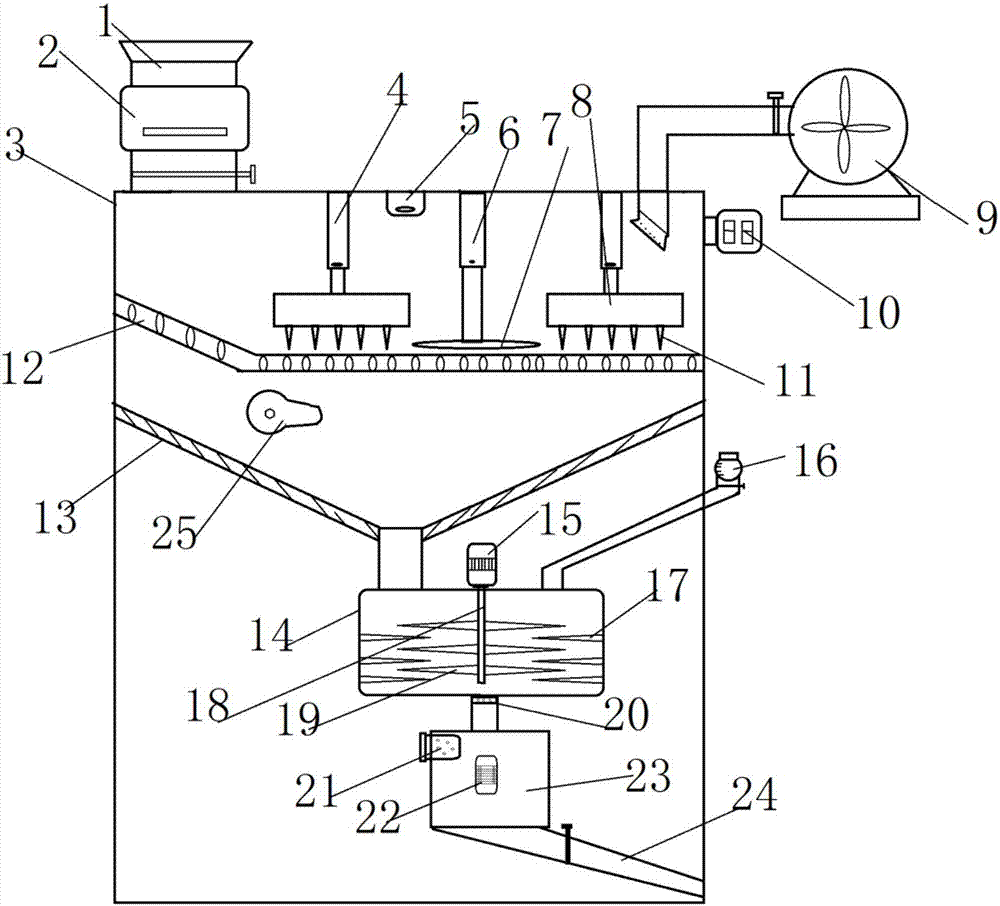

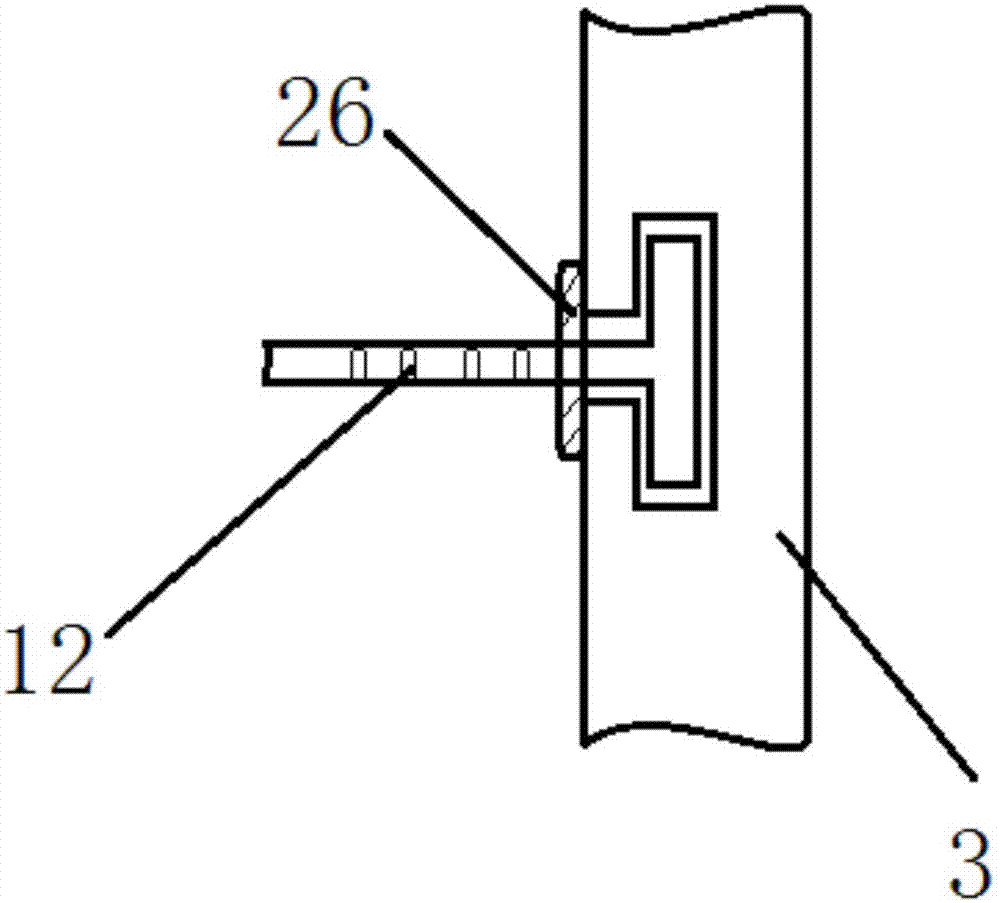

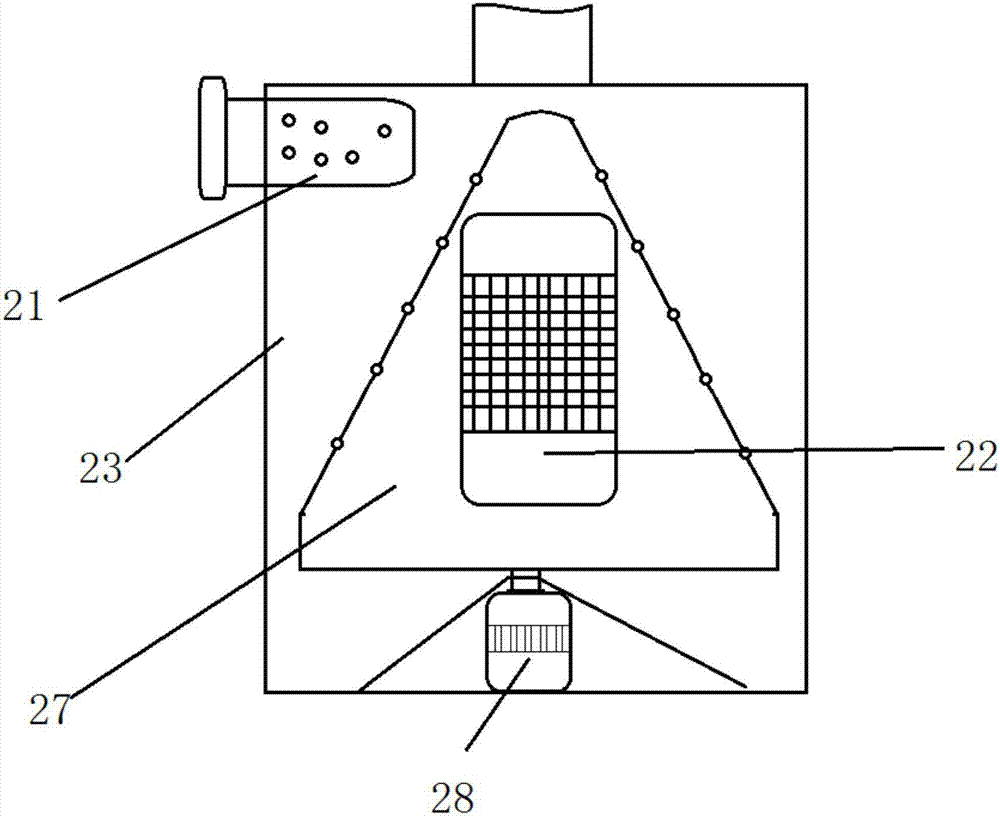

[0019] see Figure 1-3 , an environmentally friendly straw feed manufacturing equipment, including a feed pipe 1, a box body 3, an electric telescopic rod 4, a camera 5, a frying knife 7, a pressure plate 8, a blower 9, a cutter 11, a pressure plate 12, and a crushing box 14 , auxiliary agent adding pipe 16, cutting knife 17, high-speed rotating shaft 18, rotating blade 19, heater 22, drying oven 23, discharge pipe 24 and rotating conical roller 27, and the top of described casing 3 is provided with feeding pipe 1. There is a weighing device 2 on the feed pipe 1, and the weighing device 2 weighs the straw each time it enters to ensure the appropriate amount of input each time. The main component of the straw is fiber, which is mainly concentrated in the cell wall, and the content of the cell wall Accounting for more than 70%, it is composed of cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com