Rice seedling transplanter

A rice transplanter and rice technology, which is applied in planting methods, transplanting machinery, applications, etc., can solve the problems of high empty transplanting rate and the inability of the seedling delivery mechanism to adapt to seedlings, etc., and achieve the effects of low empty inserting rate, low cost, and good bite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

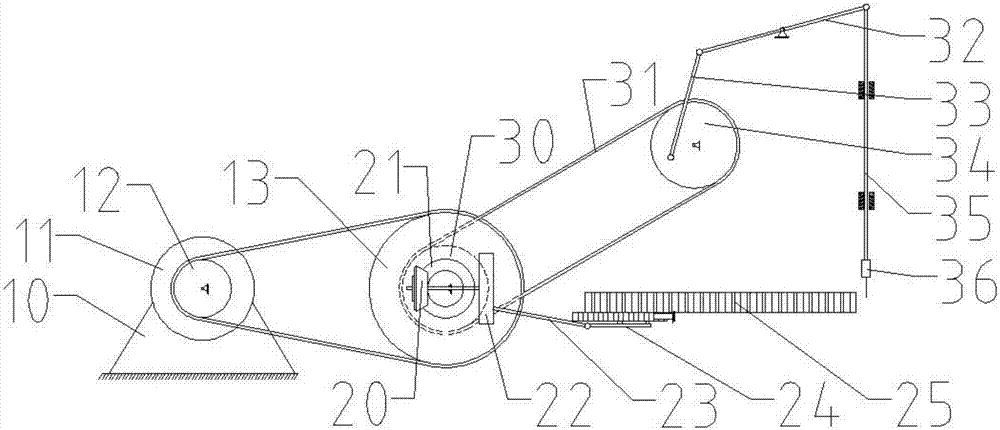

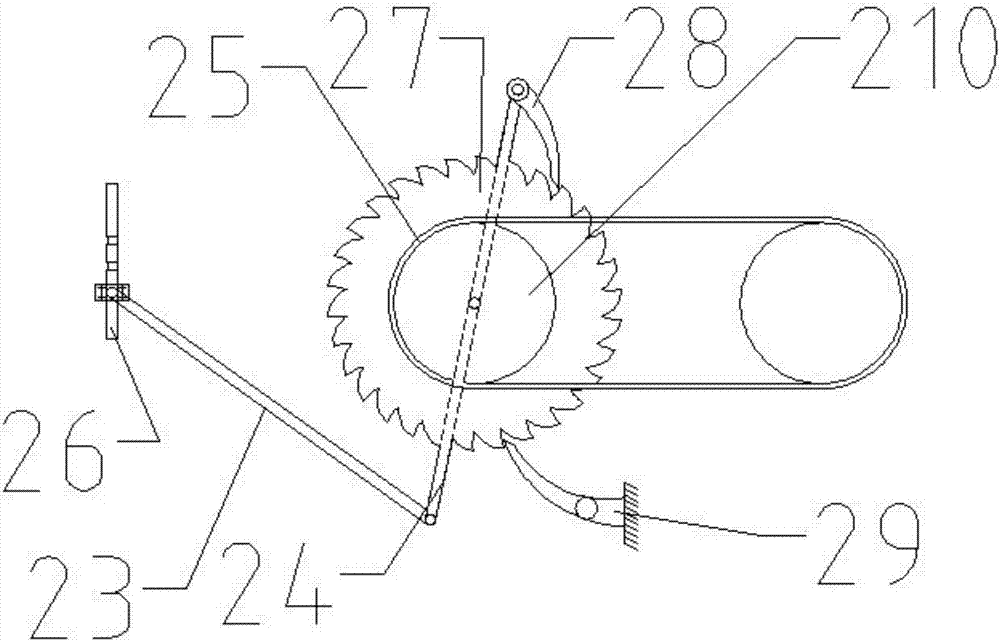

[0018] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0019] Such as Figure 1-3 Shown, a kind of rice transplanter comprises support 10, and described support 10 is fixed with motor 11, and described motor 11 is connected with small pulley 12, and small pulley 12 drives large pulley 13 described large pulley 13 A bevel gear one 20 and a sprocket one 30 are fixed on the top, the bevel gear one 20 cooperates with the bevel gear two 21, the rod where the bevel gear two 21 is located is provided with a disc 22, and the disc 22 is provided with a crank One 26. Described crank one 26 is rotationally connected with connecting rod one 23, and described connecting rod one 23 is rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com