Steel beam attachment structure

A technology for joining structures and steel beams, which is applied to building components, building structures, buildings, etc., can solve the problems of complex production and combination of bending plates, not belonging to the transmission of torque, and quality reduction, so as to improve economic efficiency and construction performance , improve quality, and save steel processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

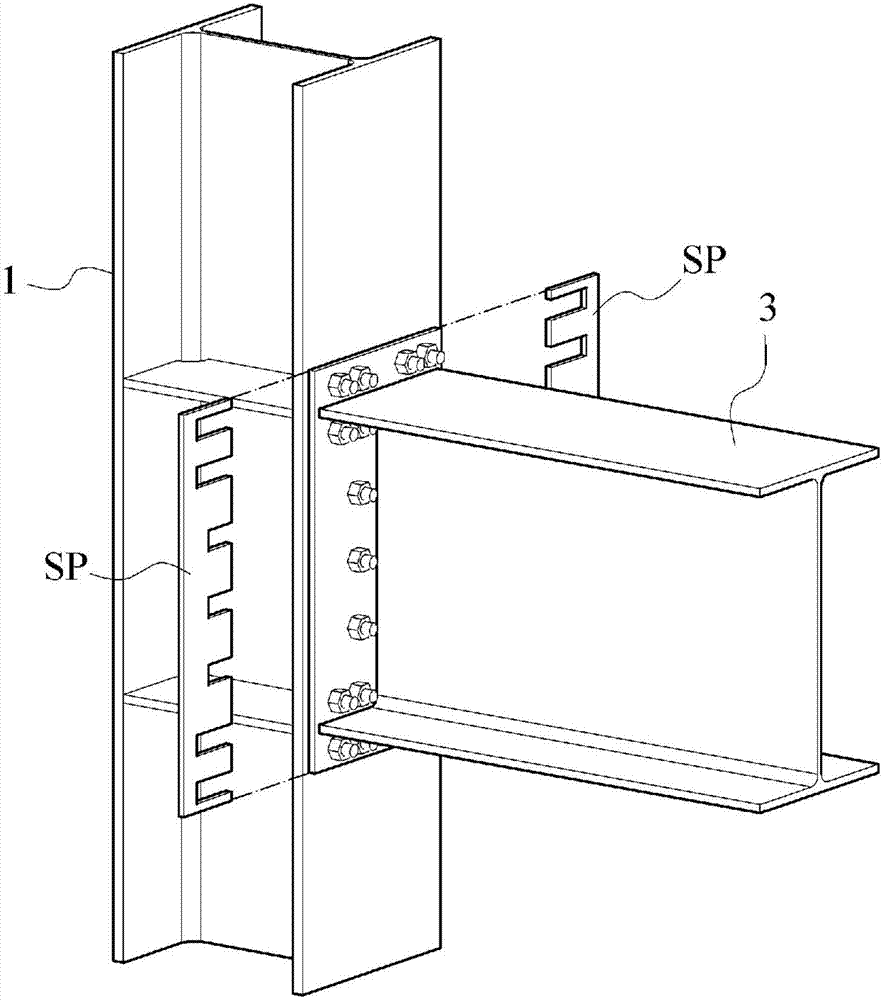

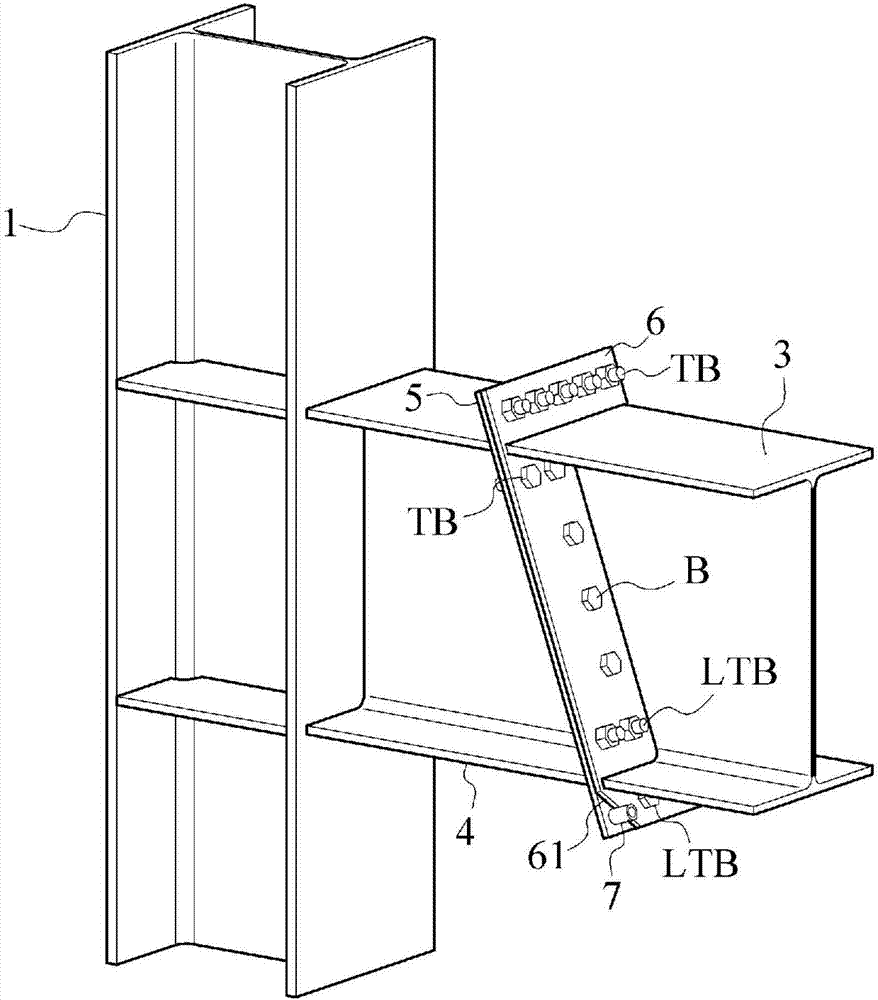

[0062] image 3 is a perspective view showing an embodiment of the steel beam joint structure of the present invention, Figure 4 is a perspective view illustrating a steel beam assembly method, Figure 5 is a perspective view showing an embodiment in which beam haunches have been incorporated.

[0063] The present invention relates to a steel beam joint structure for fixing a steel beam 3 on the side of a column 1 or girder 2 in conjunction with a bracket 4 on the side of a column 1 or girder 2 and joining the steel beam 3 to said bracket 4 steel beam joint structure.

[0064] Figure 3 to Figure 5 An embodiment in which the bracket 4 is combined to the side of the column 1 is shown, which will be described later Figure 11 to Figure 16 An embodiment in which the bracket 4 is coupled to the side of the girder 2 will be described.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com