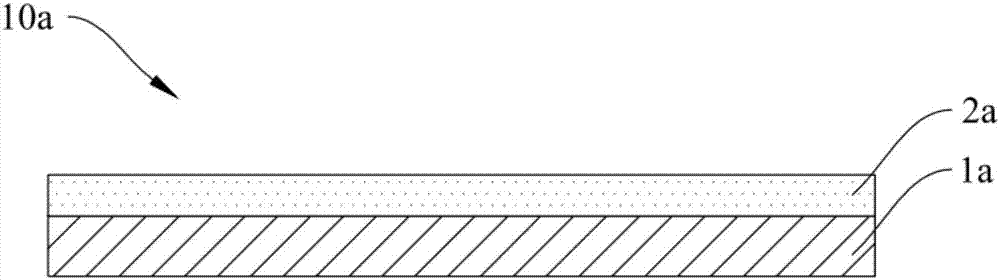

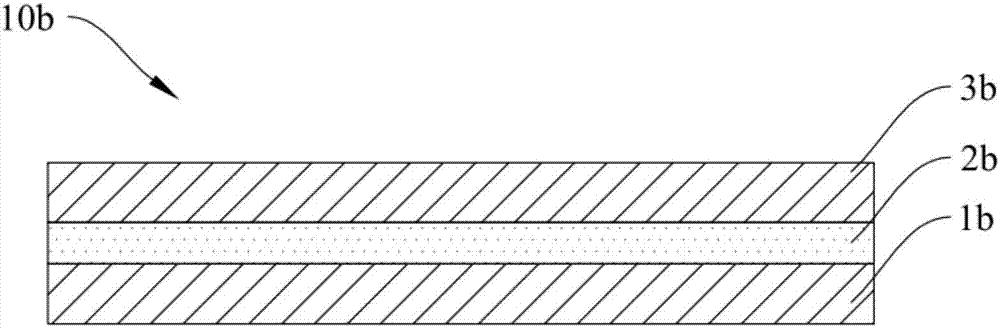

Slice, preparing method thereof, circuit substrate with slice, and preparing method of circuit substrate

A technology for substrates and circuits, which is applied in the field of forming thin sheets for cutting substrate protective films, which can solve problems such as micro scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

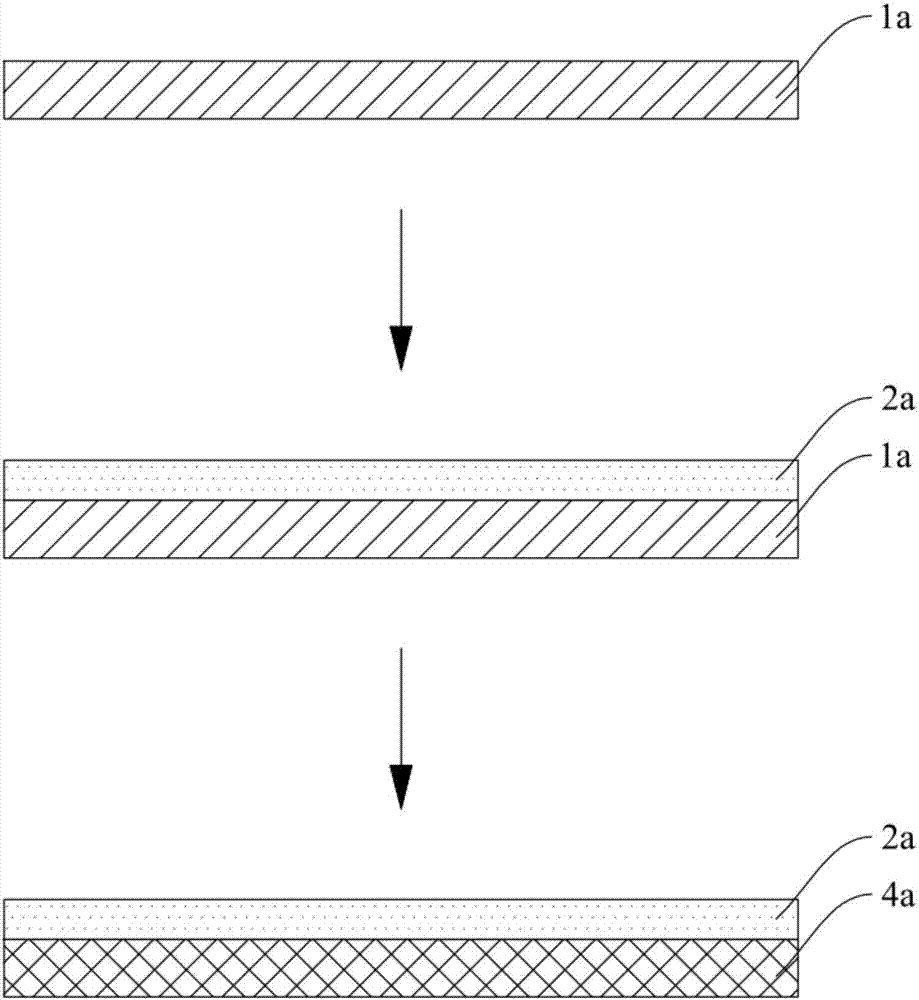

Method used

Image

Examples

Embodiment

[0048] Mix 10g of silica and 0.3g of 3-glycidoxypropyltrimethoxysilane in tetrahydrofuran at 60°C, and react for 4 hours to obtain 3-glycidoxypropyloxysilane. Silica modified by propyltrimethoxysilane.

[0049] Mix 5g of 3-glycidoxypropyltrimethoxysilane modified silica, 45g of CTBN modified epoxy resin and 45g of phenolic hardener to form a slurry, and coat it on polyterephthalic acid The first release sheet of ethylene glycol ester is baked in a continuous oven at 90° C. for 10 minutes to form a protective film layer, and then the sheet of the present invention for forming a cut substrate protective film can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com