Self pressure regulating type intelligent regulating valve

An intelligent adjustment and self-adjustment technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of unguaranteed valve life and high noise, and achieve the effect of using a wide range of differential pressure, reducing noise, and reducing cavitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in conjunction with accompanying drawing and embodiment:

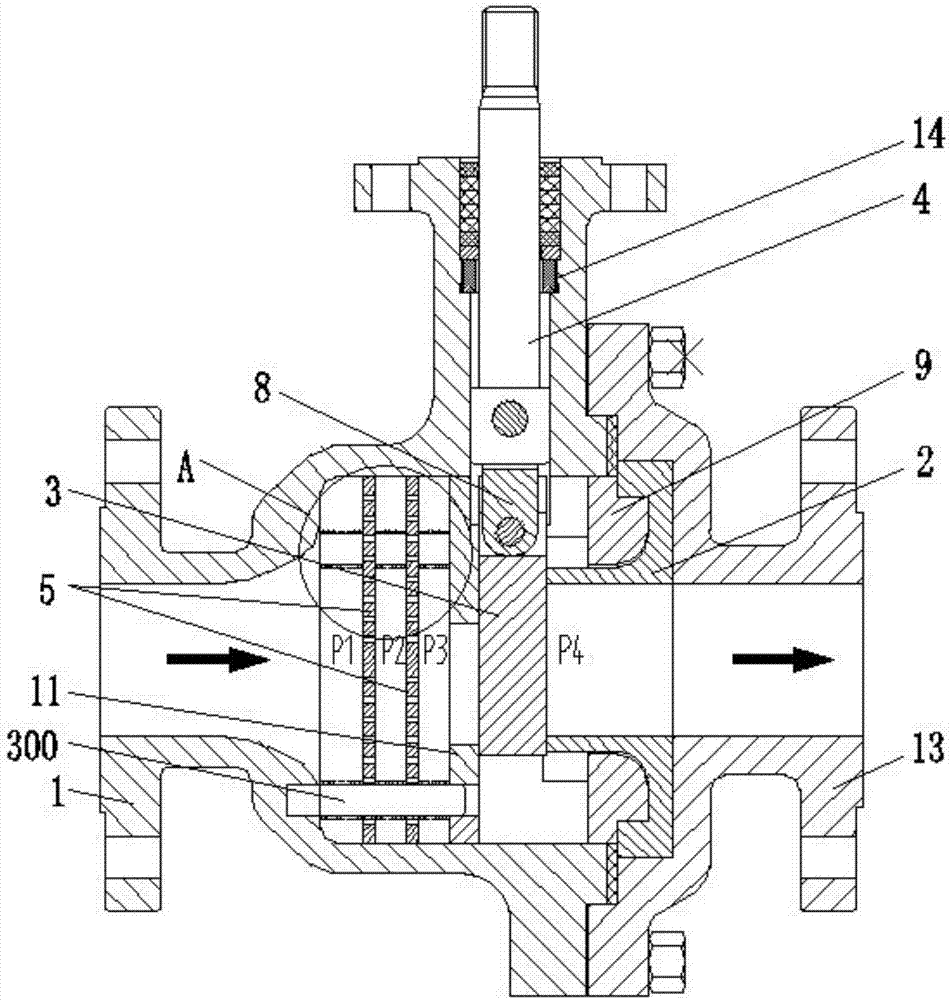

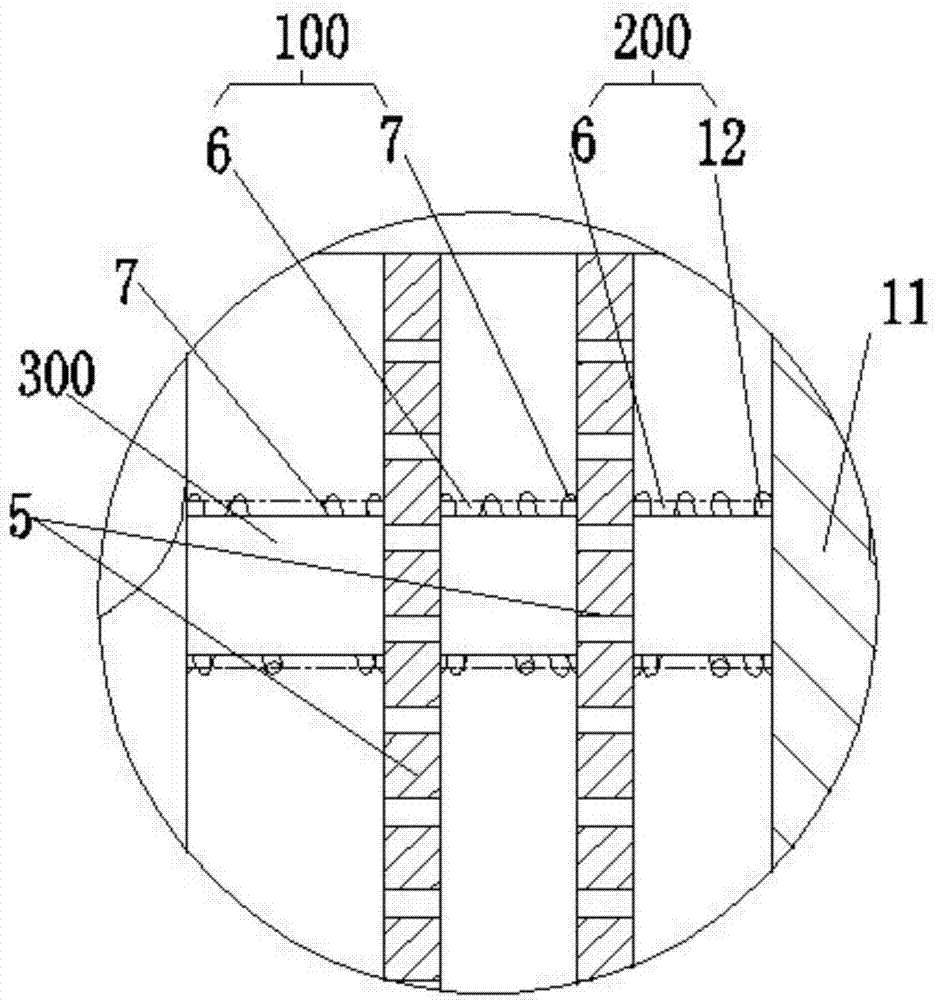

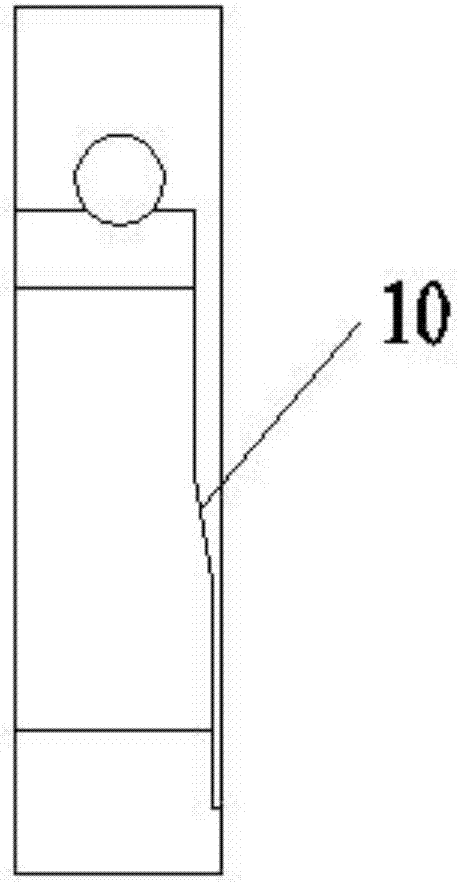

[0029] see Figure 1 to Figure 7 , as shown in the legend, a self-regulating intelligent regulating valve, including a valve body 1, a valve seat 2, a valve plate 3 and a valve stem 4, the valve body 1 is provided with a flow channel, and the valve seat 2 is located in the flow channel , the valve plate 3 cooperates with the valve seat 2 to form the on-off component of the flow channel, and the valve rod 4 drives the valve plate 3 to perform opening and closing movements respectively to open and close the flow channel respectively. The flow channel pressure regulating assembly on the fluid input side, the flow channel pressure regulating assembly includes at least two orifice plates 5, each orifice plate 5 is provided with a first elastic member 6 that drives it to reset, and the elastic force direction of the first elastic member 6 Opposite to the direction of fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com