A method for preparing polycrystalline transparent ceramics from natural fluorite minerals

A polycrystalline transparent and fluorite technology is applied in the field of preparing polycrystalline transparent ceramics to achieve the effects of shortening the preparation cycle, broadening the source range and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

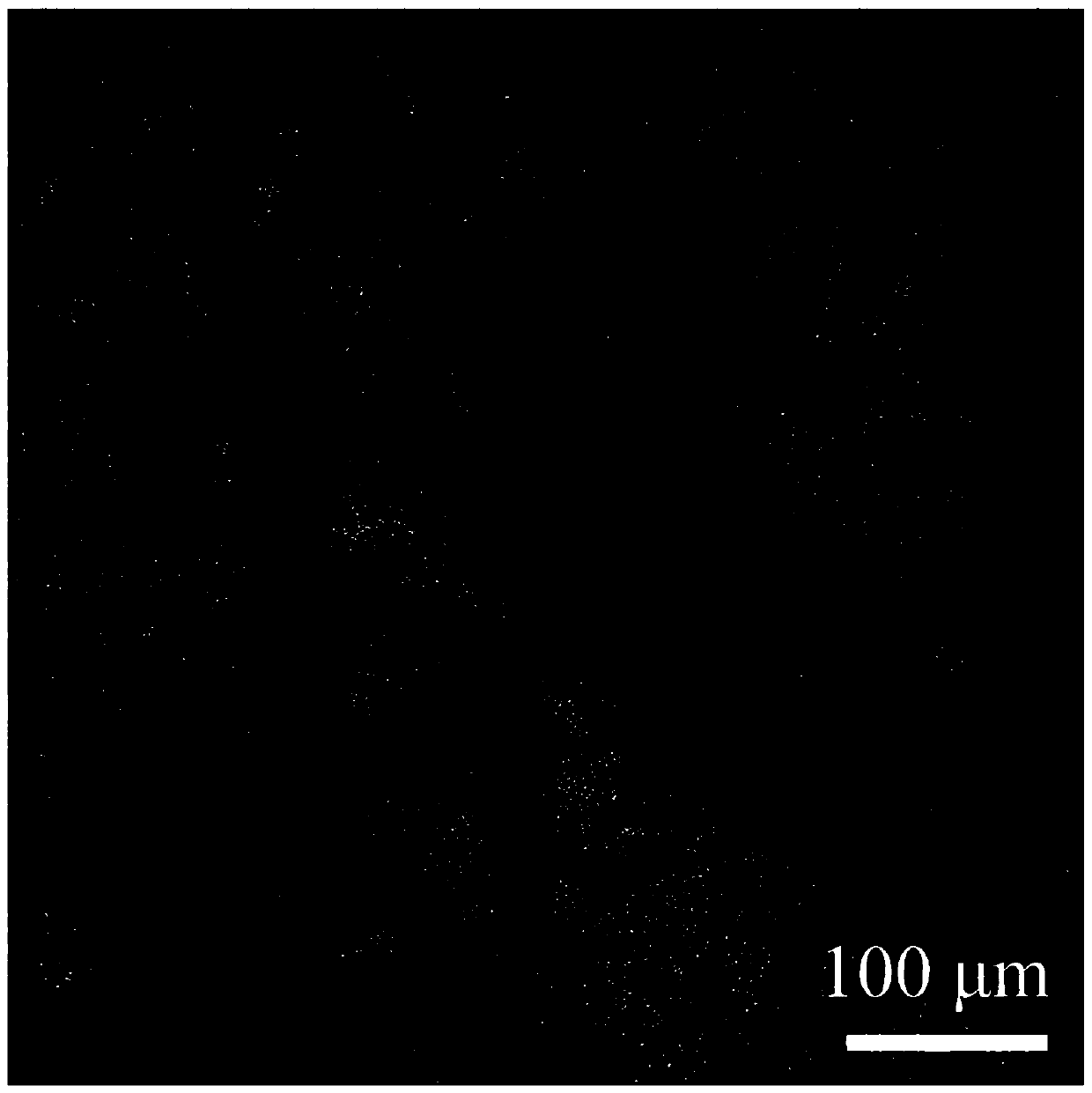

[0025] 1) Grinding of natural fluorite minerals: select natural fluorite minerals as raw materials, and grind the minerals into fine powders with a particle size of less than 100 μm;

[0026] 2) Sample loading of mineral powder raw materials: choose a graphite mold with an inner diameter of 40 mm, line the mold with graphite paper, weigh 10 g of fluorite ore powder and put it into the mold, the graphite paper separates the mold from the powder, graphite Paper thickness is 0.2 mm;

[0027] 3) Sintering of polycrystalline transparent ceramics: Put the filled graphite mold into a vacuum hot-press furnace, evacuate to better than 10 Pa, heat up to 1100 °C at a rate of 10 °C / min, and then apply a pressure of 30 MPa, keep warm 120 min;

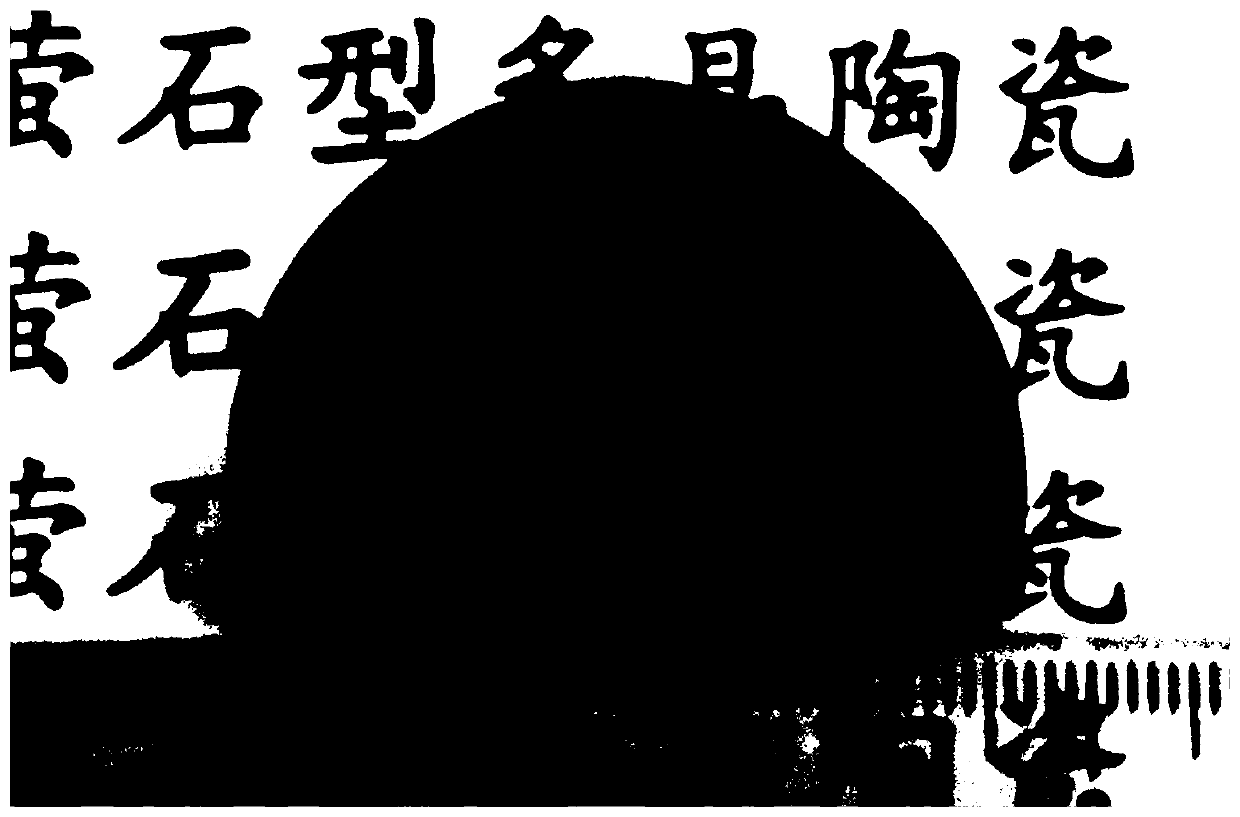

[0028] 4) Treatment of polycrystalline transparent ceramics: After the graphite mold and ceramic samples are cooled to room temperature with the furnace, they are taken out, and the ceramic samples are polished with different types of sandpaper, an...

Embodiment 2

[0031] 1) Grinding of natural fluorite minerals: select natural fluorite minerals as raw materials, and grind the minerals into fine powders with a particle size of less than 100 μm;

[0032] 2) Sample loading of mineral powder raw materials: choose a graphite mold with an inner diameter of 40 mm, line the mold with graphite paper, weigh 10 g of fluorite ore powder and put it into the mold, the graphite paper separates the mold from the powder, graphite Paper thickness is 0.2mm;

[0033] 3) Sintering of polycrystalline transparent ceramics: Put the filled graphite mold into a vacuum hot-press furnace, evacuate to better than 10 Pa, raise the temperature to 1200 °C at a rate of 10 °C / min, and then apply a pressure of 30 MPa, keep warm 120 min;

[0034] 4) Treatment of polycrystalline transparent ceramics: After the graphite mold and ceramic samples are cooled to room temperature with the furnace, they are taken out, and the ceramic samples are polished with different types of ...

Embodiment 3

[0036] 1) Grinding of natural fluorite minerals: select natural fluorite minerals as raw materials, and grind the minerals into fine powders with a particle size of less than 100 μm;

[0037] 2) Sample loading of mineral powder raw materials: choose a graphite mold with an inner diameter of 40 mm, line the mold with graphite paper, weigh 10 g of fluorite ore powder and put it into the mold, the graphite paper separates the mold from the powder, graphite Paper thickness is 0.05 mm;

[0038] 3) Sintering of polycrystalline transparent ceramics: Put the filled graphite mold into a vacuum hot-press furnace, evacuate to better than 10 Pa, heat up to 1100 °C at a rate of 15 °C / min, then apply a pressure of 30 MPa, and keep warm 60 minutes;

[0039] 4) Treatment of polycrystalline transparent ceramics: After the graphite mold and ceramic samples are cooled to room temperature with the furnace, they are taken out, and the ceramic samples are polished with different types of sandpaper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com