Co-curing forming technological method of variable-curvature composite stiffened wall plate

A technology of composite materials and reinforced wall panels, which is applied in the field of composite material manufacturing, can solve problems such as high cost, inability to fit, and heavy weight of a single mold, so as to reduce mold manufacturing and maintenance molding, and make parts molding and manufacturing fast and high. Effect of Mold Mutual Compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

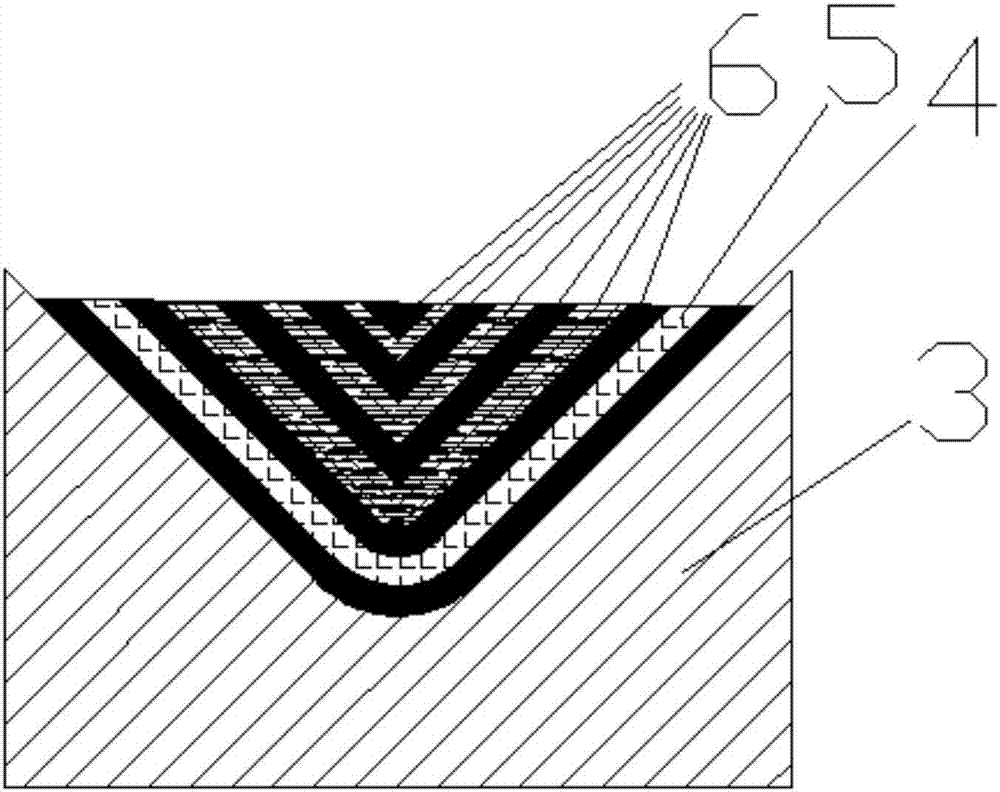

[0023] The preparation of the flexible long stringer mandrel, the long stringer flexible mandrel is cured and formed in the female mold, the inner surface of the female mold is the same as the designed stringer inner shape, firstly, the release agent is applied on the surface of the mold, and the mold is released After the agent is completely dry, a rubber layer, a prepreg layer, and a rubber layer are sequentially laid on the inner surface of the female mold. For the convenience of laying, the rubber can be pressed into a sheet. The total thickness of the rubber layer on the side of the female mold is 0.3 mm to 1 mm, and the thickness of the prepreg layer is 0.5 mm to 3 mm. The rubber on the side not attached to the mold is a filling structure, and the rubber is filled to the upper surface of the female mold. The layer can be formed by stacking multiple layers of prepreg. During the prepreg laying process, the laying direction can be controlled to reduce the bridging of the pr...

Embodiment 1

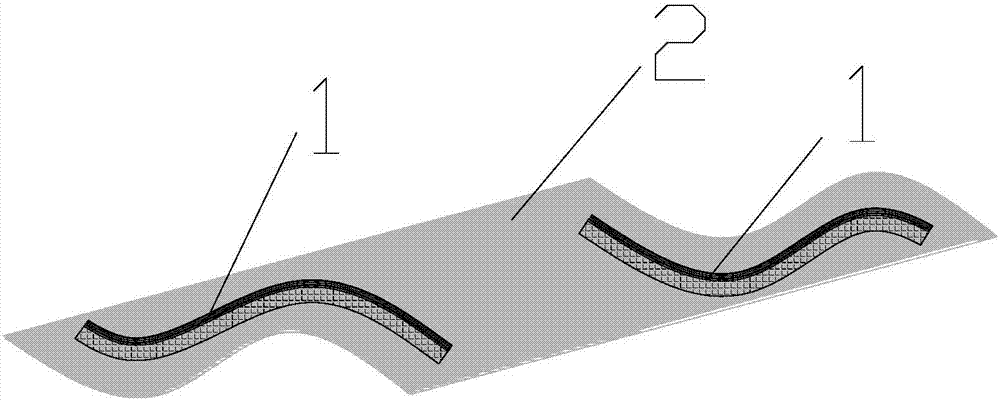

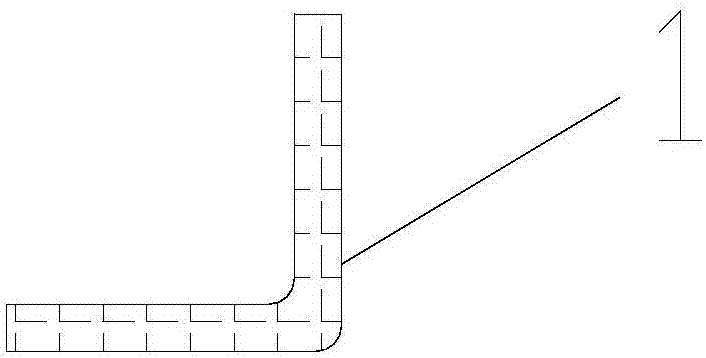

[0030] The variable-curvature composite material reinforced panel part with L-shaped stringers is a typical one in the present invention, and the method of the present invention can realize the co-curing manufacture of this type of structure, figure 1 It reveals the schematic diagram of the appearance of the L-shaped long truss reinforced variable curvature composite wall panel, which includes the L-shaped composite material long truss 1, the composite material skin 2, figure 2 reveals the cross-section of the composite stringer, image 3 Revealed the schematic diagram of the paving and laying of the mandrel mandrel of flexible composite materials, Figure 4 A schematic diagram of the laying of long stringers made of composite materials is revealed, Figure 5 Reveals the schematic diagram of the L-shaped truss-reinforced variable-curvature structural composite panel mold, Image 6 A schematic diagram of the assembly of the part blank is revealed.

[0031] The flexible stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com