External motor power conversion circuit of permanent magnet reluctance type double rotor motor

A dual-rotor motor and conversion circuit technology, applied in the direction of AC motor control, electrical components, control systems, etc., can solve problems such as the inability to ensure stable and reliable operation of external motors, low device utilization, and increased manufacturing costs, reducing switching. The effect of frequency, improving utilization, and simplifying control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

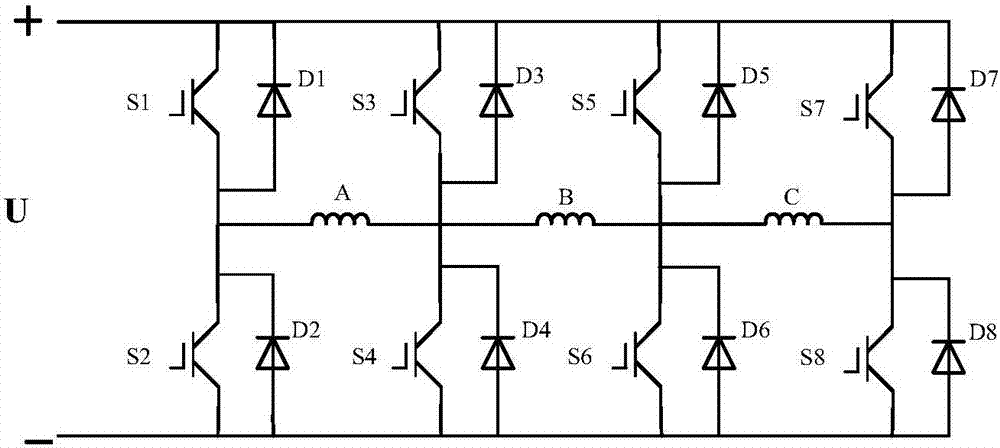

[0018] see image 3 , an external motor power conversion circuit of a permanent magnet reluctance type dual-rotor motor, including a power supply, an A-phase winding, a B-phase winding, a C-phase winding, a first bridge arm, a second bridge arm, a third bridge arm, a fourth bridge arm. The first bridge arm includes a first switch tube S1, a second switch tube S2, a first power diode D1, a second power diode D2, the first switch tube S1 is connected in series with the second switch tube S2, and the first switch tube S1 is connected in antiparallel The first power diode D1, the second switch tube S2 are antiparallel to the second power diode D2; the second bridge arm includes the third switch tube S3, the fourth switch tube S4, the third power diode D3, the fourth power diode D4, and the second bridge arm The three switching tubes S3 and the fourth switching tube S4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com