Battery pack structure

A technology of battery packs and batteries, applied in structural parts, battery pack parts, circuits, etc., can solve problems such as imperfect overcurrent protection measures, current damage to batteries or products, and failure to meet the requirements of use, so as to prevent collisions and bursting, Reduced manufacturing cost and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

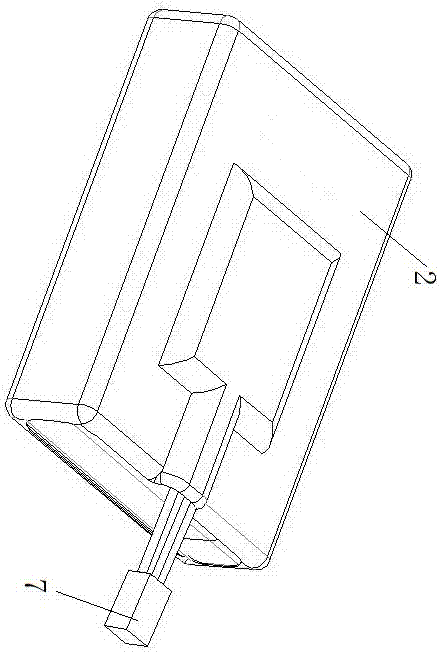

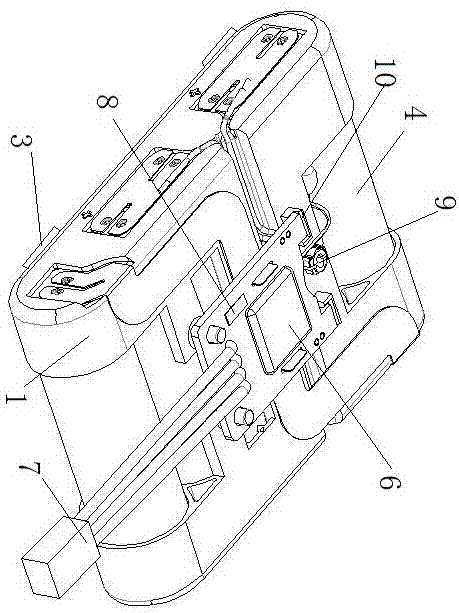

[0022] As shown in the accompanying drawings, the battery pack structure includes a bracket 1, a protective cover 2 and a buffer 3, the buffer is arranged around the bracket, and the protective cover is wrapped around the bracket and the buffer; the bracket is provided with a battery 4, installed Groove 5, protective plate 6 and connector 7, battery is placed in the installation groove, and battery can be by multi-section, and multi-section battery is connected by wire or metal sheet, present embodiment adopts nickel sheet 11 to connect all batteries together, connect The plug-in is connected to the protection board, and the battery pack of the connector outputs electric energy and signals; an over-current protector 8 and a temperature sensor 9 are arranged on the protection board, and both the over-current protector and the temperature sensor are connected to the positive pole or the negative pole of the battery.

[0023] Specifically, the overcurrent protector is a rectangula...

Embodiment 2

[0029] The color of the heat-shrinkable sleeve of the battery pack structure in the second embodiment is black, and the size of the rectangular copper foil is: 1.50mm in length and 0.75mm in width. At this time, the protection current of the overcurrent protector is greater than or equal to 15A, and the other Components and connection methods are the same as those in Embodiment 1. Because the battery pack needs to be coded during the production process, and the black battery pack code is relatively easier to identify.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com