Stop type handle automatic restoration and idling device

A technology of automatic reset and idling device, which is applied in the field of anti-theft locks, can solve the problems that the automatic reset feature of the handle is not described at the same time, the automatic reset device fails, and the key cannot be pulled out, etc., to meet the convenience of the product, the structure is simple, and the satisfaction safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

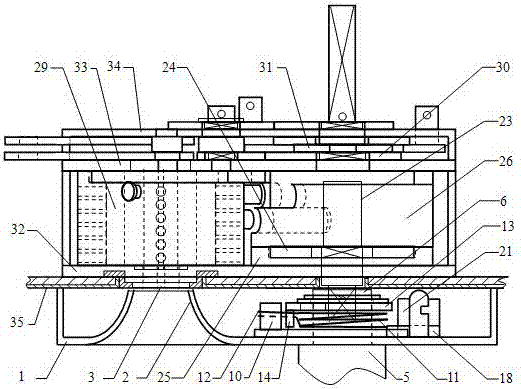

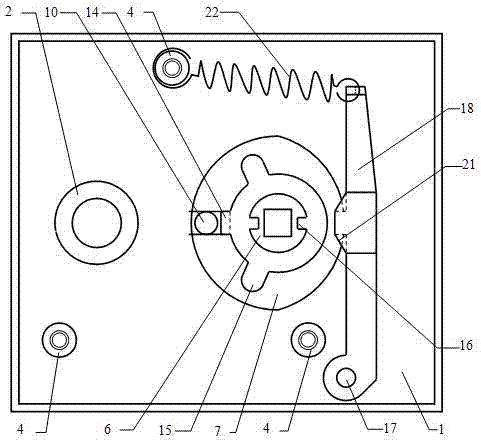

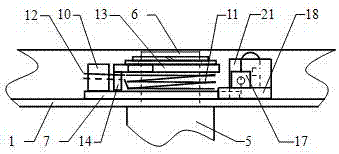

[0031] Combine below Figure 1 to Figure 15 The present invention is further described.

[0032] Such as figure 1 The overall assembly diagram of the lock shown is a technical solution in which the device of the present invention is used in conjunction with an anti-theft lock. The anti-theft lock in this solution is the product corresponding to the eight patents mentioned in the background technology. Wherein, the lock core group 29 and the cam mechanism are all installed between the anti-skid plate 32 and the back plate 33 of the lock body, the transmission mechanism of the lockset is located between the back plate 33 and the buckle cover 34, and the lock bolt and the dead bolt are positioned at the buckle cover 34. outside of the door (using an external hanging type movable connection method, not shown in the figure), the entire lock body is installed inside the door leaf, only the key opening 3 is exposed on the door leaf outer panel 35, and the outer end of the camshaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com